×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion Hydraulic Hose

Brake Hydraulic Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

47 Hydraulic Hoses found

Scion Flex Hose, Passenger Side

Part Number: 90947-02D33$85.78 MSRP: $120.42You Save: $34.64 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Right; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Manufacturer Note: RH

- Position: Passenger Side

Scion Flex Hose, Front Passenger Side

Part Number: 90947-02G34$89.10 MSRP: $125.07You Save: $35.97 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Right; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Front Passenger Side

Scion Flex Hose, Driver Side

Part Number: 90947-02D34$85.78 MSRP: $120.42You Save: $34.64 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Left; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Manufacturer Note: LH

- Position: Driver Side

Scion Flex Hose, Front Passenger Side

Part Number: 90947-02E33$88.51 MSRP: $124.23You Save: $35.72 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Right; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Front Passenger Side

Scion Flex Hose, Front Driver Side

Part Number: 90947-02G44$95.74 MSRP: $134.38You Save: $38.64 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Line, Front Left; Hydraulic Hose; Brake Hose; Brake Line; Hose, Flexible(For Front)

- Position: Front Driver Side

Scion Flex Hose

Part Number: 90118-WB078$74.37 MSRP: $104.39You Save: $30.02 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Hydraulic Hose; Clutch Hose; Hose, Clutch

Scion Flex Hose, Front Driver Side

Part Number: 90947-02E34$88.51 MSRP: $124.23You Save: $35.72 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Left; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Front Driver Side

Scion Flex Hose, Front Passenger Side

Part Number: 90947-02F92$95.74 MSRP: $134.38You Save: $38.64 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Line, Front Right; Hydraulic Hose; Brake Hose; Brake Line; Hose, Flexible(For Front)

- Position: Front Passenger Side

- Replaces: 90947-02G70

Scion Flex Hose, Driver Side

Part Number: 90947-02D77$72.51 MSRP: $101.78You Save: $29.27 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Left; Brake Hose; Brake Line; Hose, Flexible(For Front); Brake Hydraulic Hose; Hydraulic Hose

- Manufacturer Note: LH

- Position: Driver Side

- Replaces: 90947-02C32

Scion Flex Hose, Passenger Side

Part Number: 90947-02D76$72.51 MSRP: $101.78You Save: $29.27 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Right; Brake Hose; Brake Line; Hose, Flexible(For Front); Brake Hydraulic Hose; Hydraulic Hose

- Manufacturer Note: RH

- Position: Passenger Side

- Replaces: 90947-02C31

Scion Flex Hose, Rear Driver Side

Part Number: 90947-02E10$46.71 MSRP: $65.02You Save: $18.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Rear Left, Rear Left Inner; Brake Hose; Brake Line; Hose, Flexible(For Rear Driver Side); Hydraulic Hose

- Manufacturer Note: PAINTED=PINK

- Position: Rear Driver Side

Scion Flex Hose, Rear Driver Side

Part Number: 90947-02F95$43.25 MSRP: $60.19You Save: $16.94 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Line, Rear Left; Hydraulic Hose; Brake Hose; Brake Line; Hose, Flexible(For Rear Driver Side)

- Position: Rear Driver Side

Scion Flex Hose, Passenger Side

Part Number: 90947-02F94$43.56 MSRP: $60.63You Save: $17.07 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Line, Rear Right; Clutch Hose; Brake Hose; Hose, Flexible(For Rear Passenger Side); Hose, Clutch

- Position: Passenger Side

Scion Flex Hose, Front Driver Side

Part Number: 47340-WB001$41.50 MSRP: $57.77You Save: $16.27 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly, Flexible; Brake Hydraulic Hose, Front Left; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Front Driver Side

Scion Hydraulic Lines

Part Number: 31483-42080$13.73 MSRP: $19.11You Save: $5.38 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tube, Accumulator To; Hydraulic Hose; Clutch Hose; Clutch Line; Tube, Accumulator To Flexible Hose

Scion Flex Hose, Front Passenger Side

Part Number: 47330-WB001$41.50 MSRP: $57.77You Save: $16.27 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly, Flexible; Brake Hydraulic Hose, Front Right; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Front Passenger Side

Scion Flex Hose, Rear

Part Number: 90947-02C30$56.03 MSRP: $78.00You Save: $21.97 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Flexible; Brake Hydraulic Hose, Rear Left, Rear Right; Brake Hose; Brake Line; Hose, Flexible(For Rear Passenger Side); Hose, Flexible(For Rear Driver Side); Brake Hydraulic Hose; Hydraulic Hose

- Position: Rear

Scion Hydraulic Lines

Part Number: 31482-WB001$40.65 MSRP: $56.58You Save: $15.93 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tube, Release Cylinder To Flexible Hose; Hydraulic Hose; Clutch Hose; Clutch Line; Tube, Clutch Release Cylinder To Flexible Hose

- Product Specifications

- Other Name: Hose, Flexible; Brake Hydraulic Hose, Front Left; Brake Hose; Brake Line; Hose, Flexible(For Front); Hydraulic Hose

- Position: Driver Side

- Product Specifications

- Other Name: Tube, Master Cylinder; Hydraulic Hose; Clutch Hose; Clutch Line; Tube, Clutch Master Cylinder To Flexible Hose

| Page 1 of 3 |Next >

1-20 of 47 Results

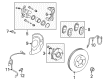

Scion Hydraulic Hose

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Scion produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Scion Hydraulic Hose? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Scion Hydraulic Hose offers a durable but elastic conduit through which pressurized fluid passes to maintain the primary systems of a Scion receptive and reliable on all of its commutes. Scion was started in 2003 with small customizable vehicles that directly addressed the needs of the young customer, it utilised aggressive online worlds and small Release Series models to generate a buzz. The brand continued to make the pricing simple to enable the shoppers to concentrate on the selection of bright colors and components that would make a car unique to them. Scion served as a moving laboratory, attempting new concepts which would eventually shape the broader Toyota family, and the brand sold over a million units before its closure in 2016, but its innovativeness continues to influence a significant number of trends in the automotive industry today. A Scion Hydraulic Hose in itself is a strengthened flexible hose that has the primary purpose to connect hydraulic components together and carry high pressurizing fluid without ruptures or bending. To install a Hydraulic Hose, it is necessary to match the specification of the hose with the Scion system, ensure that the pressure is shut and then measure the required length and cut it square and deburr the edges. Install fittings or crimp ferrules using a slide on fitting and then a little squirt of clean lubricant and tamp the fitting and assembly together without twisting the hose. Then, the Hydraulic Hose should be carefully bent in a non sharp and hot environment and clamped with clamps or shields. Complete with a short trial run by pressurizing, leak checking and re-torquing connections.