×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2009 Toyota Camry TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 TPMS Sensors found

2009 Toyota Camry TPMS Sensor

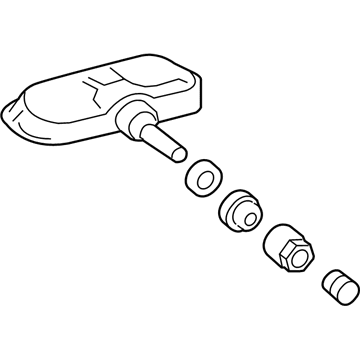

Part Number: 42607-06012$59.42 MSRP: $82.70You Save: $23.28 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Sub-Assembly, Tire; Tire Pressure Monitoring System Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Tire Sensor; Pressure Sensor; Sensor

- Replaces: 42607-06011, 42607-AD020, 42607-06010, 42607-02010, 42607-0C020

- Condition: New

- SKU: 42607-06012

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

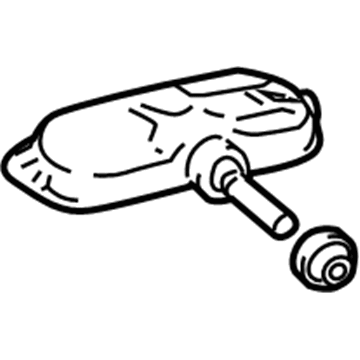

Product Specifications- Other Name: Valve Sub-Assembly, Tire; TPMS Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Valve Stem; Tire Sensor; Pressure Sensor; Pressure Valve; Sensor

- Replaces: 42607-34020, 42607-52030, 42607-35030, 42607-52010, 42607-33010, 42607-33011, 42607-35010

- Condition: New

- SKU: 42607-33012

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

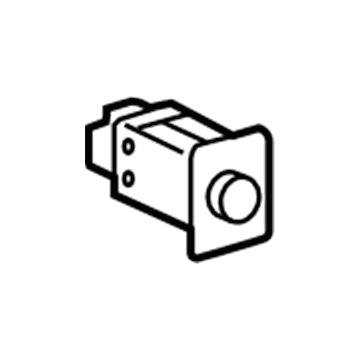

2009 Toyota Camry Tire Pressure Sensor, Driver Side

Part Number: 84746-AE010$69.19 MSRP: $97.12You Save: $27.93 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Switch, Tire Pressure; TPMS Reset Switch; TPMS Sensor Service Kit; Pressure Switch; Warning Switch; Switch; Receiver; Indicator; Switch, Tire Pressure Warning

- Position: Driver Side

- Replaces: 84746-50010, 84746-48010

- Item Weight: 0.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 84746-AE010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Camry TPMS Sensor

Looking for affordable OEM 2009 Toyota Camry TPMS Sensor? Explore our comprehensive catalogue of genuine 2009 Toyota Camry TPMS Sensor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2009 Toyota Camry TPMS Sensor Parts Q&A

- Q: How to remove the TPMS Sensor and Transmitter on 2009 Toyota Camry?A: Removing the Tire Pressure Warning Valve and Transmitter begins with separating both front and rear wheels together with the Grand Spare Tire if installed. You must start by removing the tire air after unseating the valve core and cap before you take off the washer and nut holding the tire pressure warning valve and transmitter so they can fall into the tire. The operator should maintain safekeepin of the valve core and nut together with the washer and valve cap. The procedure starts with dropping the valve and transmitter into the tire after valve detachment while making sure the valve and transmitter remain undamaged by the tire bead. Normal bead removal technique should be followed on the tire whereafter the tire pressure warning valve and transmitter can be extracted before performing the same bead removal on the lower side. Inspect the grommet for any damage before testing or changing it because broken parts require immediate replacement of the grommet and nut along with the washer.