×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2008 Toyota 4Runner TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 TPMS Sensors found

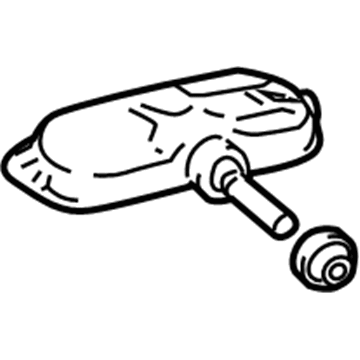

2008 Toyota 4Runner Valve Sub-Assembly, Tire

Part Number: 42607-33022$83.89 MSRP: $117.75You Save: $33.86 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: VALVE SUB-ASSY, TIRE; TPMS Sensor Service Kit; TPMS Sensor

- Replaces: 42607-30030, 42607-33021

- Item Weight: 3.10 Pounds

- Item Dimensions: 17.5 x 7.5 x 5.5 inches

- Condition: New

- SKU: 42607-33022

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

Product Specifications- Other Name: Valve Sub-Assembly, Tire; TPMS Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Valve Stem; Tire Sensor; Pressure Sensor; Pressure Valve; Sensor

- Replaces: 42607-34020, 42607-52030, 42607-35030, 42607-52010, 42607-33010, 42607-33011, 42607-35010

- Condition: New

- SKU: 42607-33012

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2008 Toyota 4Runner TPMS Sensor

Looking for affordable OEM 2008 Toyota 4Runner TPMS Sensor? Explore our comprehensive catalogue of genuine 2008 Toyota 4Runner TPMS Sensor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2008 Toyota 4Runner TPMS Sensor Parts Q&A

- Q: How to remove the TPMS Sensor and Transmitter on 2008 Toyota 4Runner?A: First step to eliminate the Tire Pressure Warning Valve and Transmitter requires the uninstallation of front and rear wheels and following steps afterwards. The second step involves taking off both valve cap and core to drain air from the tire. After sufficient tire pressure reduction you should detach the nut and washer that protects the tire pressure warning valve and transmitter so it can fall into the tire cavity. The shoe of a tire remover should be used to disengage the bead but extra caution is needed to protect the sensor from the tire bead interference. Remove the tire bead on the upper side followed by extraction of the tire pressure warning valve and transmitter from the tire space before releasing the lower tire bead. The complete removal of the nut together with the washer and grommet set should be performed even when there is no grommet damage.