×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2001 Toyota Tacoma Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Ball Joints found

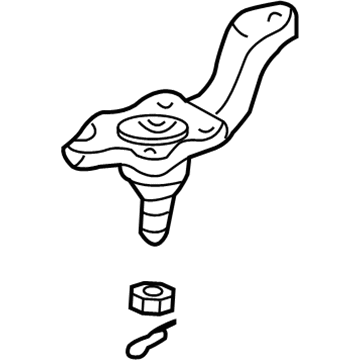

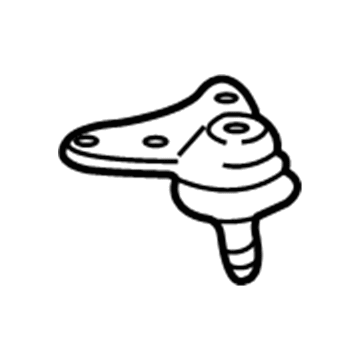

2001 Toyota Tacoma Lower Ball Joint, Driver Side

Part Number: 43340-39585$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Driver Side

- Replaces: 43340-39287, 43340-39286

- Item Weight: 8.80 Pounds

- Item Dimensions: 5.5 x 3.4 x 2.4 inches

- Condition: New

- SKU: 43340-39585

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Lower Ball Joint, Passenger Side

Part Number: 43330-39815$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Passenger Side

- Replaces: 43330-39366, 43330-39367

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.3 x 3.2 x 2.5 inches

- Condition: New

- SKU: 43330-39815

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

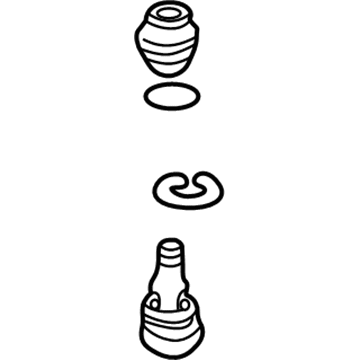

2001 Toyota Tacoma Upper Ball Joint, Front

Part Number: 43310-39016$49.94 MSRP: $69.51You Save: $19.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Upper; Upper Ball Joints; Front Upper Ball Joint Assembly for Driver & Passenger Side.

- Position: Front Upper

- Replaces: 43310-39085, 43310-39065

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.5 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43310-39016

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Lower Ball Joint, Front Passenger Side

Part Number: 43330-39556$134.88 MSRP: $190.93You Save: $56.05 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39555

- Part Name Code: 43330K

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.4 x 3.2 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43330-39556

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

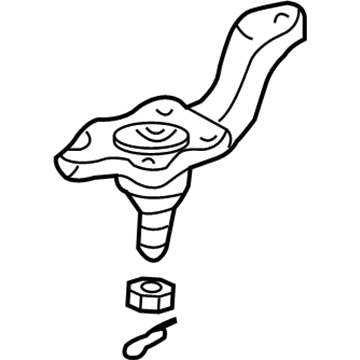

2001 Toyota Tacoma Lower Ball Joint, Front Driver Side

Part Number: 43340-39436$117.66 MSRP: $165.16You Save: $47.50 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Joint Assembly, Lower Ball, Front Driver Side; Suspension Ball Joint; Ball Joint

- Position: Front Driver Side

- Replaces: 43340-39435

- Part Name Code: 43340A

- Item Weight: 5.20 Pounds

- Item Dimensions: 5.4 x 3.4 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43340-39436

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Lower Ball Joint, Front Passenger Side

Part Number: 43330-39565$93.25 MSRP: $130.89You Save: $37.64 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39355

- Part Name Code: 43330K

- Item Weight: 3.00 Pounds

- Item Dimensions: 5.4 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43330-39565

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Lower Ball Joint, Front Driver Side

Part Number: 43340-39445$73.70 MSRP: $103.44You Save: $29.74 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Joint Assembly, Lower Ball, Front Driver Side; Suspension Ball Joint; Ball Joint

- Position: Front Driver Side

- Replaces: 43340-39275

- Part Name Code: 43340A

- Item Weight: 2.90 Pounds

- Item Dimensions: 5.4 x 3.3 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43340-39445

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

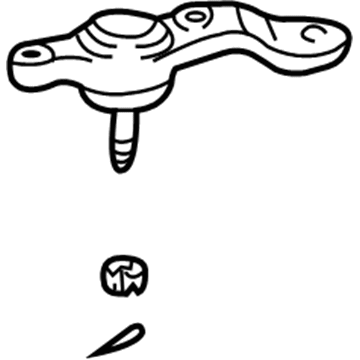

2001 Toyota Tacoma Upper Ball Joint, Driver Side

Part Number: 43360-39095$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Left Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Driver Side; Suspension Ball Joint; Ball Joint

- Position: Driver Side

- Part Name Code: 43360

- Item Weight: 1.90 Pounds

- Item Dimensions: 7.1 x 4.6 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43360-39095

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Upper Ball Joint, Passenger Side

Part Number: 43350-39105$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper B; Suspension Ball Joint, Front Right Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Passenger Side

- Part Name Code: 43350

- Item Weight: 1.90 Pounds

- Item Dimensions: 5.3 x 3.7 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43350-39105

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Tacoma Ball Joint

Looking for affordable OEM 2001 Toyota Tacoma Ball Joint? Explore our comprehensive catalogue of genuine 2001 Toyota Tacoma Ball Joint. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2001 Toyota Tacoma Ball Joint Parts Q&A

- Q: How to service and repair the lower ball joint on 2001 Toyota Tacoma?A: A proper servicing and repairing process of the lower ball joint starts by taking off the front wheel and tightly securing it with 110 Nm (1,150 kgf-cm, 83 ft. lbs.) torque. Unscrew the four bolts securing the tie rod end to an 80 Nm torque without bolt removal before removing the cotter pin and nut at 90 Nm torque. Tighten the nut up to additional 60 degrees if the holes do not align properly. Special Service Tool: 09610-20012 should be used to disconnect the steering knuckle-bound tie rod end. The lower ball joint removal process starts by extracting the cotter pin and nut with 140 Nm (1,450 kgf-cm, 103 ft. lbs.) torque and finishing the nut tightening process to 60 degrees if required. You should use Special Service Tool: 09628-62011 to disconnect the lower ball joint from the lower suspension arm while facing the mission-directed position of the cotter pin hole. Remove the 4 bolts next and lift the upper suspension arm and steering knuckle to extract the lower ball joint after you support the upper suspension arm and steering knuckle properly. To check the lower ball joint rotation condition inspect the ball joint stud when rotating it 5 times backward and forward before applying a torque wrench that turns the nut once during 2 - 4 seconds at 0.1 - 2.5 Nm (11 - 25 kgf-cm, 1 - 22 inch lbs.). The reverse order of mounting should be followed for installation then inspect the wheel alignment after swimming.