×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Tacoma Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Ball Joints found

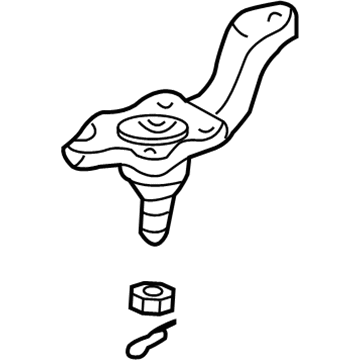

2000 Toyota Tacoma Lower Ball Joint, Driver Side

Part Number: 43340-39585$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Driver Side

- Replaces: 43340-39287, 43340-39286

- Item Weight: 8.80 Pounds

- Item Dimensions: 5.5 x 3.4 x 2.4 inches

- Condition: New

- SKU: 43340-39585

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Tacoma Lower Ball Joint, Passenger Side

Part Number: 43330-39815$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Passenger Side

- Replaces: 43330-39366, 43330-39367

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.3 x 3.2 x 2.5 inches

- Condition: New

- SKU: 43330-39815

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

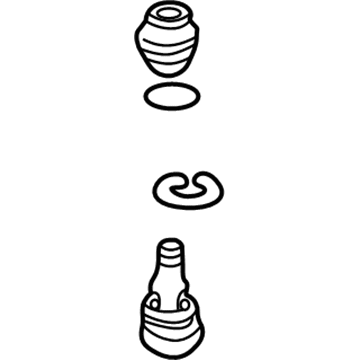

2000 Toyota Tacoma Upper Ball Joint, Front

Part Number: 43310-39016$49.94 MSRP: $69.51You Save: $19.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Upper; Upper Ball Joints; Front Upper Ball Joint Assembly for Driver & Passenger Side.

- Position: Front Upper

- Replaces: 43310-39085, 43310-39065

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.5 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43310-39016

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Tacoma Lower Ball Joint, Front Passenger Side

Part Number: 43330-39565$93.25 MSRP: $130.89You Save: $37.64 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39355

- Part Name Code: 43330K

- Item Weight: 3.00 Pounds

- Item Dimensions: 5.4 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43330-39565

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

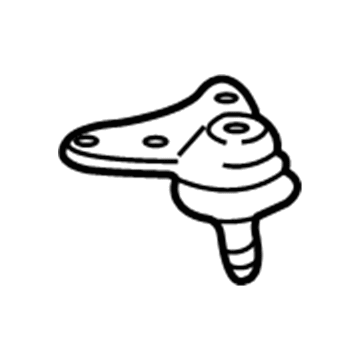

2000 Toyota Tacoma Lower Ball Joint, Front Driver Side

Part Number: 43340-39445$73.70 MSRP: $103.44You Save: $29.74 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Joint Assembly, Lower Ball, Front Driver Side; Suspension Ball Joint; Ball Joint

- Position: Front Driver Side

- Replaces: 43340-39275

- Part Name Code: 43340A

- Item Weight: 2.90 Pounds

- Item Dimensions: 5.4 x 3.3 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43340-39445

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

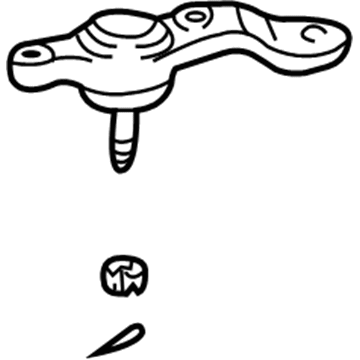

2000 Toyota Tacoma Upper Ball Joint, Driver Side

Part Number: 43360-39095$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Left Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Driver Side; Suspension Ball Joint; Ball Joint

- Position: Driver Side

- Part Name Code: 43360

- Item Weight: 1.90 Pounds

- Item Dimensions: 7.1 x 4.6 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43360-39095

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Tacoma Upper Ball Joint, Passenger Side

Part Number: 43350-39105$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper B; Suspension Ball Joint, Front Right Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Passenger Side

- Part Name Code: 43350

- Item Weight: 1.90 Pounds

- Item Dimensions: 5.3 x 3.7 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43350-39105

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Tacoma Ball Joint

Looking for affordable OEM 2000 Toyota Tacoma Ball Joint? Explore our comprehensive catalogue of genuine 2000 Toyota Tacoma Ball Joint. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Tacoma Ball Joint Parts Q&A

- Q: How to service and repair the lower ball joint on 2000 Toyota Tacoma?A: Start lower ball joint service and repair by first removing the front wheel according to a specific torque level of 110 Nm. The first step involves loosening the tie rod end bolts to 80 Nm while keeping them in place before removing the nut and cotter pin along with tightening the nut to 90 Nm. To combat misalignment between cotter pin holes during installation, further increase nut torque to 60. The special service tool 09610-20012 enables you to detach the tie rod end from the steering knuckle. When replacing the lower ball joint one must remove its retaining nut and cotter pin utilizing 140 Nm (1,450 kgf-cm, 103 ft. lbs.) of torque while tightening the nut up to 60° when the holes are misaligned during reinstallation. The lower ball joint disconnecting procedure requires Special Service Tool: 09628-62011 to separate the lower ball joint from the lower suspension arm with the cotter pin hole facing forward when reinstalling. The 4 bolts should get removed until you can lift the upper suspension arm and steering knuckle to extract the lower ball joint. Afterwards establish stable support for the upper suspension arm and steering knuckle. Before installing the nut check lower ball joint rotation by rotating the ball joint stud five times mutually in both directions and perform the torque wrench operation starting from one continuous turn every 2 to 4 seconds while inspecting the torque reading on the fifth turn to achieve a turning torque at 0.1 to 2.5 Nm (11-25 kgf-cm, 1-22 inch lbs.). After installation you should examine the front wheel alignment. The sequence for installation runs in the opposite direction of removal.