×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tundra TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 TPMS Sensors found

Toyota Tundra Tire Pressure Sensor, Driver Side

Part Number: 84746-AE010$69.19 MSRP: $97.12You Save: $27.93 (29%)Ships in 1-3 Business Days

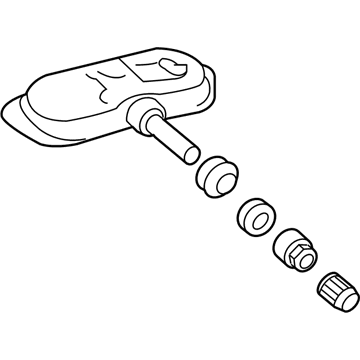

Toyota Tundra TPMS Sensor

Part Number: 42607-0C101$66.63 MSRP: $93.53You Save: $26.90 (29%)Ships in 1-3 Business Days

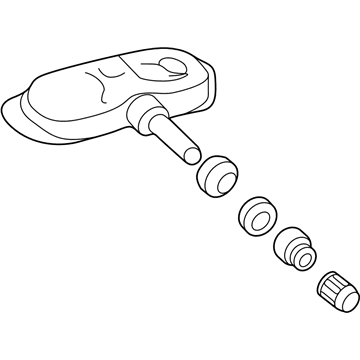

Toyota Tundra TPMS Sensor

Part Number: 42607-0C091$96.33 MSRP: $135.21You Save: $38.88 (29%)Ships in 1-2 Business Days

Toyota Tundra TPMS Sensor

Part Number: 42607-0C080$61.13 MSRP: $85.81You Save: $24.68 (29%)Ships in 1-3 Business Days

Toyota Tundra TPMS Sensor

Part Number: 42607-06030$59.89 MSRP: $84.06You Save: $24.17 (29%)Ships in 1 Business Day

Toyota Tundra TPMS Sensor

Part Number: 42607-04020$60.38 MSRP: $84.75You Save: $24.37 (29%)Ships in 1-2 Business Days

Toyota Tundra TPMS Sensor

Part Number: 42607-02050$61.70 MSRP: $86.61You Save: $24.91 (29%)Ships in 1-3 Business DaysToyota Tundra TPMS Sensor

Part Number: 42607-04011$58.94 MSRP: $82.04You Save: $23.10 (29%)Ships in 1-3 Business DaysToyota Tundra TPMS Sensor

Part Number: 90942-A5005$10.74 MSRP: $14.96You Save: $4.22 (29%)Ships in 1 Business Day

Toyota Tundra TPMS Sensor

Choose genuine TPMS Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM TPMS Sensor for your Toyota Tundra? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tundra parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

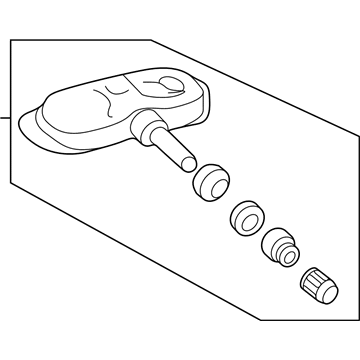

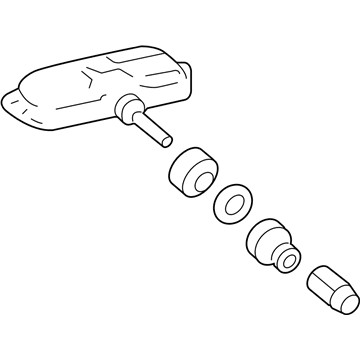

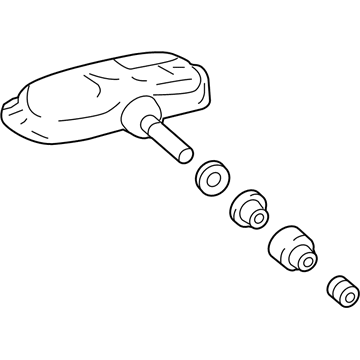

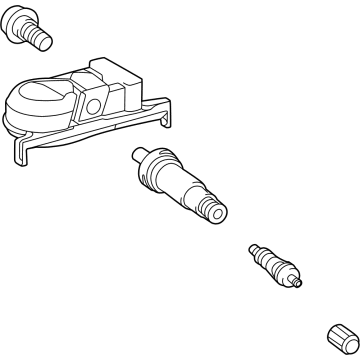

This is a genuine TPMS sensor used on Toyota Tundra cars, famous for their reliability and performance of the vehicles. This is another important sensor that helps in improving efficiency as well as safety in the sense that it reminds drivers about the high or low limit of tire pressure. Each Toyota Tundra manufactured has its TPMS sensor for all the tires, and the mounting type can be clamp-in, screw-in, and snap-in. The Toyota Tundra utilizes two primary types of TPMS: The two categories are Indirect TPMS (iTPMS) and Direct TPMS (dTPMS). Although iTPMS has software based estimated that is user friendly, dTPMS has the features of an actual monitoring in that the hardware sensors give accurate tire pressure readings in real time. This difference enables the Toyota Tundra owners to make a decision on which system will suit them most. The Toyota Tundra TPMS Sensor is available for use with a host of Tundra models making it possible for vehicle owners of any generation of this much-raved about pickup truck to enjoy the prime in tire performance. Being a reliable truck, the Toyota Tundra has received lots of commendations such as the Motor Trend's Truck of the Year; thus, the Toyota Tundra has carved a place for itself in the market. The TPMS Sensor is unlike every other gadget since it is very functional and at the same time improves on the overall experience of driving; this is why it is very important for any Toyota Tundra driver who is very much interested in safety and performance.

Toyota Tundra TPMS Sensor Parts and Q&A

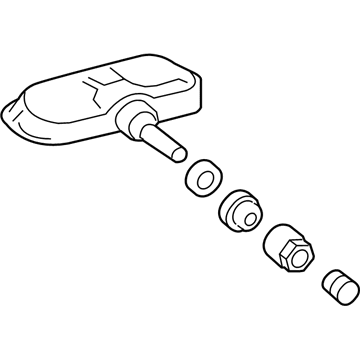

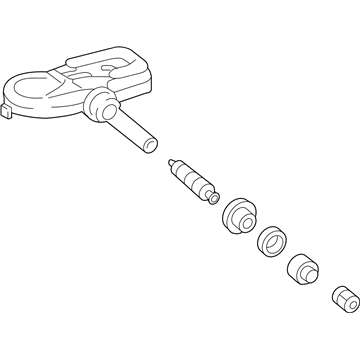

- Q: How to install the TPMS Sensor and transmitter on Toyota Tundra?A:The tire pressure warning valve and transmitter requires installation through the inside surface of a wheel rim before setting the printed side towards the outside. The valve and rim hole must be checked for clear signs of damage and foreign objects because wrong installation can harm the valve and cause high-speed signal failure. Writing down the transmitter ID before installation becomes essential because the registration process applies to all replacements. Reusing the valve and transmitter requires installation of a new grommet found in new units. Place the washer to the valve side from the rim and tighten the nut turning it to 4.0 Nm (41 kgf-cm, 35 in-lbf) while checking for foreign matter or lubricant. Set the wheel disc on a mounting machine before installing the lower tire bead while placing the valve and transmitter main body in the designated shaded region that avoids possible interference. Add the upper bead to the wheel after rope clamp removal and inflate the tire while re-tightening the nut to correct specifications before testing for air leaks with soapy water. The torque setting should be at 131 Nm (1336 kgf-cm, 97 ft-lbf) when installing aluminum wheels while steel wheel installation requires 209 Nm (2131 kgf-cm, 154 ft-lbf). Before starting the process you must inspect the tire while recording transmitter ID and complete initialization steps when all tires maintain the correct pressure levels. The DATA LIST should show actual tire pressures as a confirmation after all necessary repairs are done.

- Q: How to remove the TPMS Sensor and Transmitter on Toyota Tundra?A:The first step for removing the Tire Pressure Warning Valve and Transmitter is to remove the tire. You need to both remove tire air pressure through the valve core removal and disassemble the tire pressure warning valve and transmitter nut and washer to let the transmitter drop into the tire space. Save all elements you remove from the Tire Pressure Warning Valve and Transmitter because you will need them later for reassembly. The tire bead requires disengagement through a shoe of tire remover tool but maintain caution toward the sensor to prevent damage from bead contact. Pull away the bead from the top surface before you can extract the tire pressure warning valve and transmitter from inside the tire and then remove the bottom bead from its position. Users should check the grommet for damage because it serves as a non-reusable component. In case the grommet exhibits damage, users should replace both the washer and nut.