×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Tundra TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 TPMS Sensors found

Product Specifications

Product Specifications- Other Name: Valve Sub-Assembly, Tire; TPMS Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Valve Stem; Tire Sensor; Pressure Sensor; Pressure Valve; Sensor

- Replaces: 42607-34020, 42607-52030, 42607-35030, 42607-52010, 42607-33010, 42607-33011, 42607-35010

- Condition: New

- SKU: 42607-33012

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Tundra Tire Pressure Sensor, Driver Side

Part Number: 84746-AE010$69.19 MSRP: $97.12You Save: $27.93 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Switch, Tire Pressure; TPMS Reset Switch; TPMS Sensor Service Kit; Pressure Switch; Warning Switch; Switch; Receiver; Indicator; Switch, Tire Pressure Warning

- Position: Driver Side

- Replaces: 84746-50010, 84746-48010

- Item Weight: 0.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 84746-AE010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Tundra TPMS Sensor

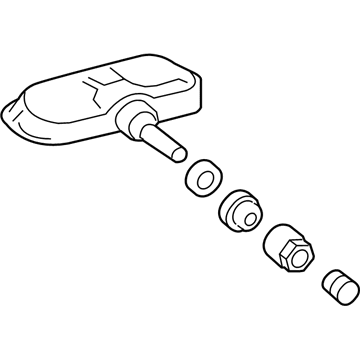

Part Number: 42607-04011$58.94 MSRP: $82.04You Save: $23.10 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Sub-Assembly, Tire; Tire Pressure Monitoring System Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Sensor

- Replaces: 42607-04010, 42607-AD010, 42607-0C010

- Item Weight: 1.40 Pounds

- Item Dimensions: 6.4 x 6.2 x 5.3 inches

- Condition: New

- SKU: 42607-04011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Tundra TPMS Sensor

Looking for affordable OEM 2006 Toyota Tundra TPMS Sensor? Explore our comprehensive catalogue of genuine 2006 Toyota Tundra TPMS Sensor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Tundra TPMS Sensor Parts Q&A

- Q: How to replace and dispose of a TPMS Sensor valve sub-assembly on 2006 Toyota Tundra?A: A screwdriver can be used to open the back cover so the battery and base board covered by silicone resin are visible before disconnecting the two battery terminals that connect the base board and extracting the battery. Start by detaching the front and rear tires then penetrate the valve core to lower tire pressure while you remove the nut and washer that connects the tire pressure monitor valve sub-assy until the sensor drops inside the wheel. Use the tire remover shoe toDetach the bead while safeguarding the tire pressure monitor valve then eliminate the sensor by pulling out both of its sides. First inspect the inner grommet on the tire pressure monitor valve sub-assy and check it for any signs of damage or cracks before deciding on replacement with a new grommet along with other parts. Insert the tire pressure monitor valve through the installation hole of the rim while facing the print surface outward from inside the rim before verifying its exterior appearance. The tire pressure monitor washer should be mounted onto the valve from the inner rim side before tightening its nut to 4.0 Nm (41 kgf-cm, 35 inch lbs.) torque when no foreign objects are visible. Inflate the tire then secure the valve nut to its torques specification while checking for air leaks by soaking a rag with soapy water. Position the wheel disc into the mounting machine while carefully installing the lower bead starting by correctly positioning the sensor main body to prevent interference followed by upper bead installation without clamp occurrence. The last installation step includes fitting both front and rear wheels to 103 Nm torque (1,050 kgf-cm, 76 ft. lbs.) and performing inspections of the tire and recording the transmitted ID and verifying the operation of the tire pressure warning system. Special Service Tool: 09843-18040.