×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

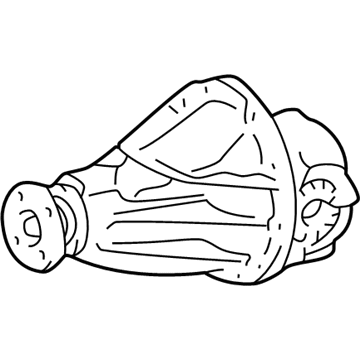

OEM Toyota Tacoma Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

50 Differentials found

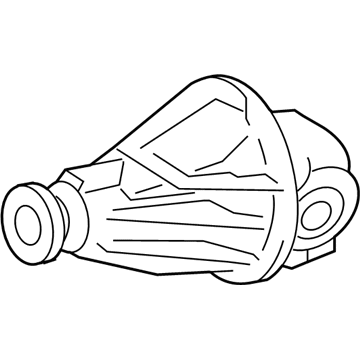

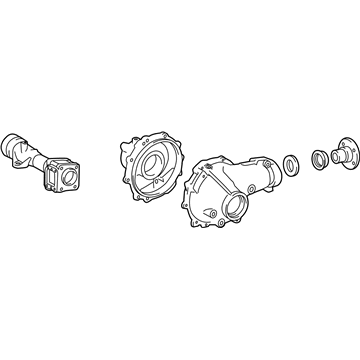

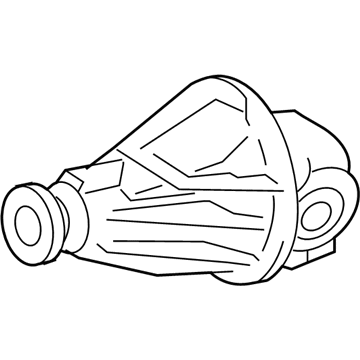

Toyota Tacoma Differential Carrier, Rear

Part Number: 41110-34341$1419.65 MSRP: $2080.51You Save: $660.86 (32%)Ships in 1-2 Business Days

Toyota Tacoma Differential Carrier, Rear

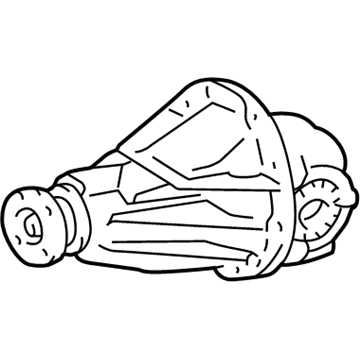

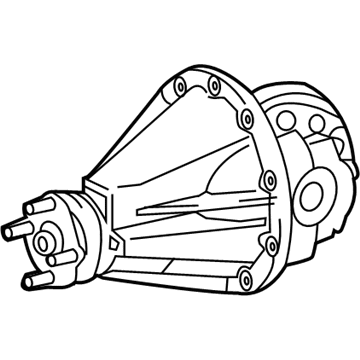

Part Number: 41110-35A21$2535.81 MSRP: $3716.26You Save: $1180.45 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-34241$1851.72 MSRP: $2713.71You Save: $861.99 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-35861$2535.81 MSRP: $3716.26You Save: $1180.45 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

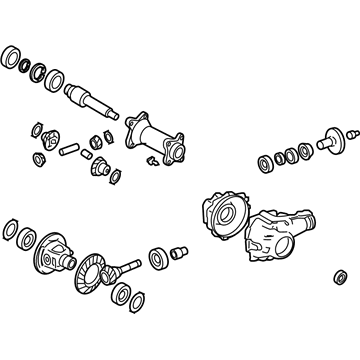

Part Number: 41110-35D81$2070.46 MSRP: $3034.28You Save: $963.82 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Case, Rear

Part Number: 41301-60061$762.60 MSRP: $1117.59You Save: $354.99 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-35820$1492.17 MSRP: $2186.80You Save: $694.63 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-35B40$1263.45 MSRP: $1851.59You Save: $588.14 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-0K580$1454.60 MSRP: $2131.74You Save: $677.14 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Assembly

Part Number: 41301-04010$575.66 MSRP: $843.63You Save: $267.97 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-35E50$1894.53 MSRP: $2776.45You Save: $881.92 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-35A31$1381.40 MSRP: $2024.45You Save: $643.05 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-35B70$1985.33 MSRP: $2909.52You Save: $924.19 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Assembly, Rear

Part Number: 41303-0K010$1472.88 MSRP: $2158.52You Save: $685.64 (32%)Ships in 1-3 Business DaysToyota Tacoma Carrier Case, Rear

Part Number: 41101-35151$416.42 MSRP: $610.27You Save: $193.85 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-34261$2245.81 MSRP: $3291.27You Save: $1045.46 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-35B90$1894.53 MSRP: $2776.45You Save: $881.92 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-43030$1296.73 MSRP: $1900.37You Save: $603.64 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Front

Part Number: 41110-35E10$1894.53 MSRP: $2776.45You Save: $881.92 (32%)Ships in 1-3 Business DaysToyota Tacoma Differential Carrier, Rear

Part Number: 41110-35A41$1381.40 MSRP: $2024.45You Save: $643.05 (32%)

| Page 1 of 3 |Next >

1-20 of 50 Results

Toyota Tacoma Differential

Choose genuine Differential that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Differential for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Tacoma Differential Parts and Q&A

- Q: How to remove and replace the rear differential carrier assembly (without differential lock) on Toyota Tacoma?A:Before starting the process of differential carrier assembly removal and replacement without differential lock technicians should isolate the negative battery terminal and remove the rear wheel and drain brake fluid. You must first detach the rear brake drum sub-assembly before proceeding to take off the front and rear brake shoes. The repair process starts with the removal of propeller shaft assembly for 2WD driver type regular cab units while 2WD drive type except regular cab requires the removal of the propeller with center bearing shaft assembly and 4WD drive type regular cab needs the same propeller shaft assembly removed as 2WD followed by the removal of propeller with center bearing shaft assembly for 4WD drive type except regular cab. After draining differential oil users must separate the rear Speed Sensors from both sides by using the same steps employed for the right side application as for the left. After separating the No.3 parking brake cable assembly as for the No.2 cable proceed with the same method. Procede with the removal of the backed-up Axle Shaft from both sides by implementing the same technique used for the right side that was employed for the left. Use caution when removing the ten nuts from the differential carrier assembly because doing so may damage its removal surface. After taking off the assembly you should remove the rear differential carrier gasket from the differential carrier assembly.

- Q: How to install the rear differential carrier assembly without a differential lock on Toyota Tacoma?A:The first step to install the rear differential carrier assembly without differential lock requires a two-part process. Clean the differential carrier assembly and axle housing contact surfaces before applying liquid gasket on both sides but excluding the stud bolt. You should position 10 new nuts and washers on the differential carrier assembly and torques them to 45 Nm (459 kgf-cm, 33 ft-lbf). The installation of rear Axle Shafts with backing plates should be carried out on both left and right sides adopting a standardized procedure. Execute installation of the No.3 and No.2 parking brake cable assemblies on both sides using the same method. The rear Speed Sensor installation process should be done once for both the left and right sides. The propeller shaft assembly needs installation according to drive type and cab configuration through the correct procedures that differ for 2WD and 4WD systems or Regular Cab and Access/Dual Cab setups. Move on to the installation of brake shoes on both the rear and front while inspecting the brake drum installation for the rear braking system before installing the rear brake drum sub-assembly. The service process includes two steps which are adjusting the rear drum brake shoe clearance followed by filling reservoirs with brake fluids for multiple boosters before performing master cylinder and brake line bleeding operations for all Brake Boosters. The examination of the reservoir fluid content along with brake fluid leak detection is essential. Differential oil maintenance requires inspection and search for leakage during the process. The final step includes installing the rear wheel with a torque setting of 113 Nm (1,152 kgf-cm, 83 ft-lbf) and performing proper checks on the parking brake system followed by connecting the cable to the negative battery terminal using 3.9 Nm (40 kgf-cm, 35 in-lbf) of torque. The VSC sensor signal needs verification for both components.