×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tacoma Air Bag

Air Bag Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Air Bags found

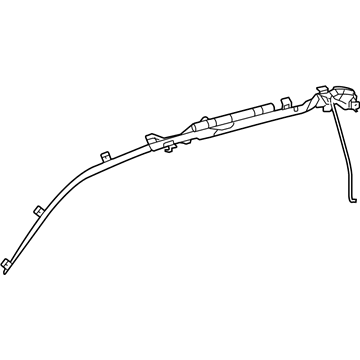

Toyota Tacoma Inflator Curtain, Passenger Side

Part Number: 62170-04012$1179.48 MSRP: $1728.54You Save: $549.06 (32%)

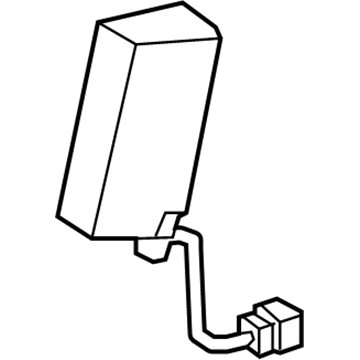

Toyota Tacoma Side Impact Inflator Module, Driver Side

Part Number: 73920-04040$378.17 MSRP: $554.22You Save: $176.05 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Passenger Side

Part Number: 62170-04010$1198.44 MSRP: $1756.32You Save: $557.88 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Driver Side

Part Number: 62180-04021$769.86 MSRP: $1128.24You Save: $358.38 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Driver Side

Part Number: 62180-04010$1165.44 MSRP: $1707.96You Save: $542.52 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Passenger Side

Part Number: 62170-04050$1111.61 MSRP: $1629.08You Save: $517.47 (32%)Toyota Tacoma Inflator Curtain, Driver Side

Part Number: 62180-04050$1111.61 MSRP: $1629.08You Save: $517.47 (32%)Toyota Tacoma Knee Inflator Module, Lower Passenger Side

Part Number: 73990-04011-C0$784.16 MSRP: $1149.19You Save: $365.03 (32%)Ships in 1-3 Business DaysToyota Tacoma Side Impact Inflator Module, Driver Side

Part Number: 73920-04050$379.87 MSRP: $556.71You Save: $176.84 (32%)Ships in 1-2 Business DaysToyota Tacoma Head Air Bag, Driver Side

Part Number: 62180-04060$1160.19 MSRP: $1700.27You Save: $540.08 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Driver Side

Part Number: 62180-04040$1097.76 MSRP: $1608.78You Save: $511.02 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Passenger Side

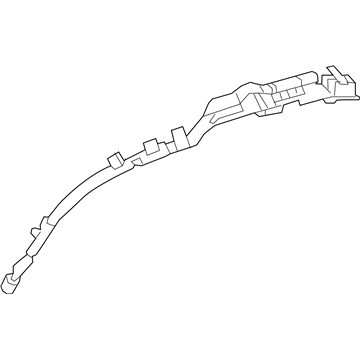

Part Number: 62170-04031$663.96 MSRP: $973.05You Save: $309.09 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Driver Side

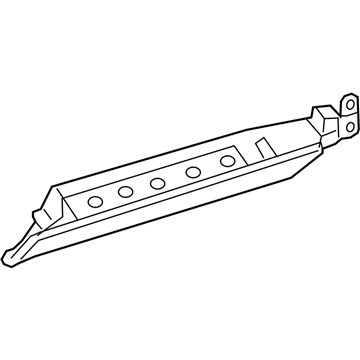

Part Number: 62180-04031$663.96 MSRP: $973.05You Save: $309.09 (32%)Ships in 1-3 Business DaysToyota Tacoma Passenger Air Bag, Upper

Part Number: 73960-04060$577.25 MSRP: $845.97You Save: $268.72 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Passenger Side

Part Number: 62170-04040$1097.76 MSRP: $1608.78You Save: $511.02 (32%)Ships in 1-3 Business DaysToyota Tacoma Inflator Curtain, Driver Side

Part Number: 62180-04012$1179.48 MSRP: $1728.54You Save: $549.06 (32%)Toyota Tacoma Inflator Curtain, Passenger Side

Part Number: 62170-04021$769.86 MSRP: $1128.24You Save: $358.38 (32%)

| Page 1 of 2 |Next >

1-20 of 25 Results

Toyota Tacoma Air Bag

Choose genuine Air Bag that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Air Bag for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Tacoma Air Bag Parts and Q&A

- Q: What are the essential steps to take after a collision regarding the front passenger Air Bag assembly and related components on Toyota Tacoma?A:System diagnostic testing must follow visual assessment of the front passenger Air Bag assembly after any collision takes place. Any vehicle that does not encounter collisions needs its front passenger Air Bag door checked for minor breaks, tiny fractures and clear color alterations. Prior to any inspection of the front passenger Air Bag assembly following a collision without deployment check for damage on the Air Bag door as well as any wire harness and connector damage and instrument panel and reinforcement deformation. Deformation of the instrument panel requires a panel replacement instead of attempting repairs. During new Air Bag assembly installation keep a uniform distance between the Air Bag door and instrument panel without allowing any obstruction to occur. When an Air Bag deploys in a vehicle you must recheck diagnostics while examining all instrument panel and reinforcement components and glove compartment door for deformation and inspecting the connectors and wire harnesses for any damage. The examination of the steering wheel pad should include a search for any cuts or cracks as well as discoloration while confirming that it presents no obstacles to wheel control. The replacement of the steering wheel pad becomes necessary when the horn button contact plate shows any deformation. The SRS wire harness at the instrument panel should have no exposed wires or breaks and all its connectors need to be standard yellow. The Air Bag Sensor assembly must undergo fault evaluation and needs replacing after it has deployed. A diagnostic test should be performed on the front Air Bag sensor before inspecting any front fender damage to ensure its bracket remains undamaged while also checking for broken paint and sensor case or connector defects. Replacement of front Air Bag sensors needs to be performed when they are deployed or faulty or dropped using proper removal methods and installation steps.

- Q: What are the inspection and repair procedures for the front passenger Air Bag assembly after a collision on Toyota Tacoma?A:A thorough examination along with repair work must be performed for front passenger Air Bag assemblies after any accident. Vehicles that have not participated in collisions need to start with a diagnostic system check for reading and erasing diagnostic trouble codes. Check the instrument panel surrounding the assembly because it should show no breaks and must have clear appearance and normal coloring. Before inspecting the front passenger Air Bag assembly after a car accident without Air Bag deployment check the diagnostic system and inspect the removed part for wire harness and connector damage and instrument panel and reinforcement damage and look for marked discoloration, cuts and minute cracks. The correct procedure for front passenger Air Bag assembly replacement and removal and installation should be followed during the process. The instrument panel together with its reinforcement requires complete replacement as a new part whenever deformations or cracks become visible. Special Service Tool: 999-9999.