×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Sienna Wiper Motor

Windshield Wiper Motor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

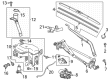

9 Wiper Motors found

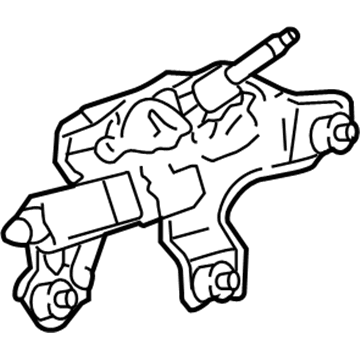

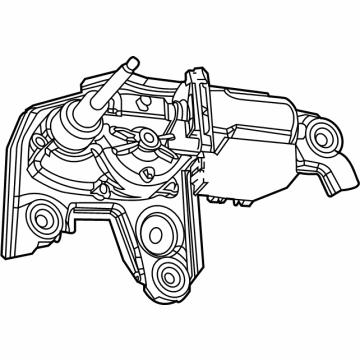

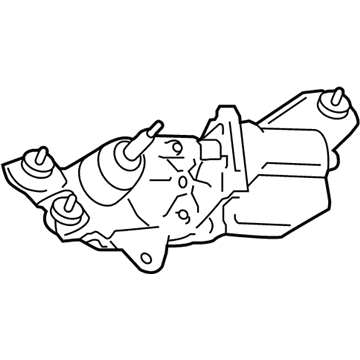

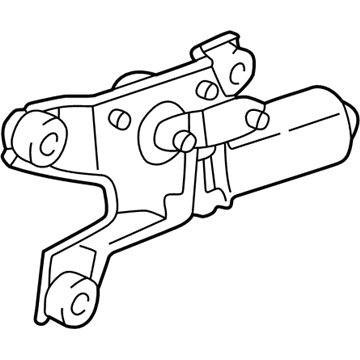

Toyota Sienna Motor & Bracket, Rear

Part Number: 85130-AE010$181.15 MSRP: $258.64You Save: $77.49 (30%)Ships in 1-3 Business Days

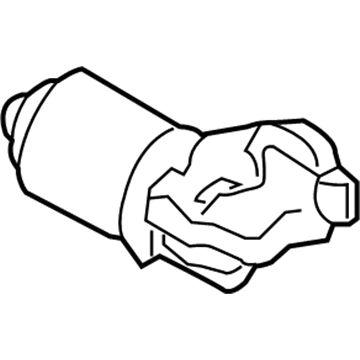

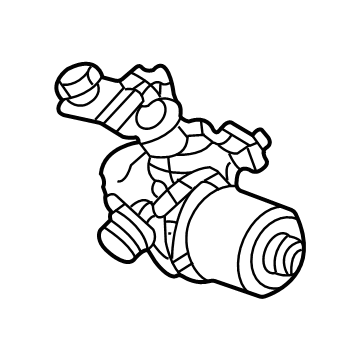

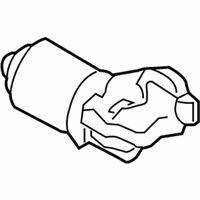

Toyota Sienna Front Motor

Part Number: 85110-08030$154.74 MSRP: $219.05You Save: $64.31 (30%)Ships in 1-3 Business Days

Toyota Sienna Wiper Motor, Front

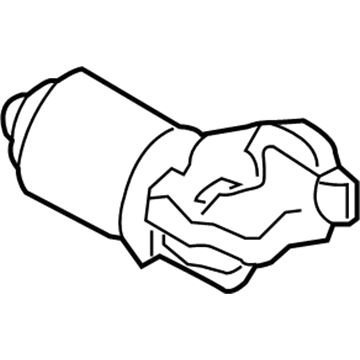

Part Number: 85110-08010$192.45 MSRP: $274.77You Save: $82.32 (30%)Ships in 1-3 Business DaysToyota Sienna Wiper Motor, Rear

Part Number: 85130-0E120$136.05 MSRP: $192.60You Save: $56.55 (30%)Ships in 1-3 Business DaysToyota Sienna Motor & Bracket, Rear

Part Number: 85130-08010$157.20 MSRP: $222.55You Save: $65.35 (30%)Ships in 1-3 Business DaysToyota Sienna Wiper Motor, Front

Part Number: 85110-08050$170.95 MSRP: $242.01You Save: $71.06 (30%)Ships in 1-3 Business DaysToyota Sienna Front Motor

Part Number: 85110-AE010$197.69 MSRP: $282.26You Save: $84.57 (30%)Ships in 1-3 Business Days

Toyota Sienna Wiper Motor

Choose genuine Wiper Motor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Wiper Motor for your Toyota Sienna? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sienna parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Sienna Wiper Motor Parts and Q&A

- Q: How to install the windshield wiper motor assembly on Toyota Sienna?A:The windshield wiper motor assembly installation requires MP grease application on the crank arm pivot before assembly to the windshield wiper link assembly through 3 bolts tightened to 7.5 Nm (76 kgf-cm, 66 in-lbf). The installment requires 4 bolts which need to be tightened up to 5.5 Nm (56 kgf-cm, 49 in-lbf) along with connector attachment. You should mount the cowl top ventilator louver sub-assembly by using 6 claws as points of attachment. Begin by stopping the motor at automatic stop while operating the front wiper arm LH before using a round file and wire brush to clean the serration part of the wiper arm so you can install the arm and its nut tightened to a torque of 20 Nm while manually supporting the arm hinge. The process of repair continues with the front wiper arm RH before installing the arm with a torque of 20 Nm (205 kgf-cm, 15 ft-lbf) but still requires hand stabilization of the arm hinge. The wiper operation under fluid should be performed to verify wiping quality and check that the front wiper avoids vehicle collisions before securing the wiper arm caps.

- Q: How to remove the rear wiper motor and bracket on Toyota Sienna?A:You need to start with the rear wiper arm removal through dismantling the head cap and the nut. Start by removing the back door garnish center and proceed to take off the back door side garnish from the left-hand side of the vehicle before removing the power back door rod. The service requires removal of the back door side garnish on the right-hand side and backing door strap cover and back door trim board assembly. The removal process requires the disconnecting and removal of the rear wiper motor assembly after breaking the 3 bolts and cutting the connector free from installation.