×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

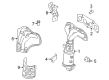

OEM Scion Catalytic Converter

Cat. Converter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Catalytic Converters found

Product Specifications

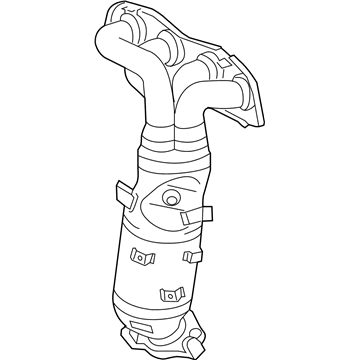

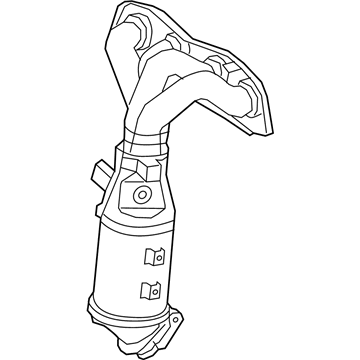

Product Specifications- Other Name: Converter Sub-Assembly; Manifold Converter; Manifold; Converter Sub-Assembly, Exhaust Manifold

- Manufacturer Note: (L),*212

- Replaces: 25051-36010

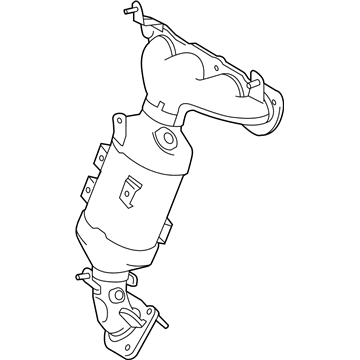

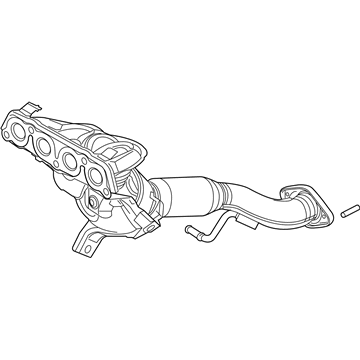

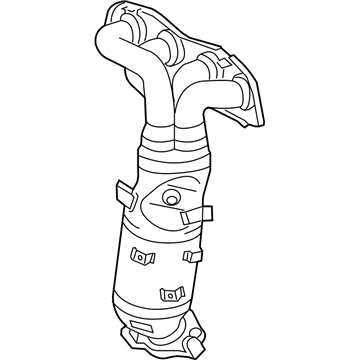

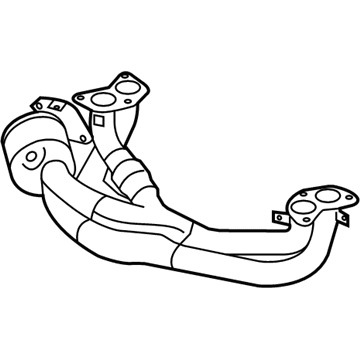

Scion Exhaust Manifold

Part Number: 25051-28340$682.58 MSRP: $850.73You Save: $168.15 (20%)Ships in 1 Business DayProduct Specifications- Other Name: Converter Sub-Assembly; Catalytic Converter with Integrated Exhaust Manifold; Manifold Converter; Converter Sub-Assembly, Exhaust Manifold

- Replaces: 25051-28360

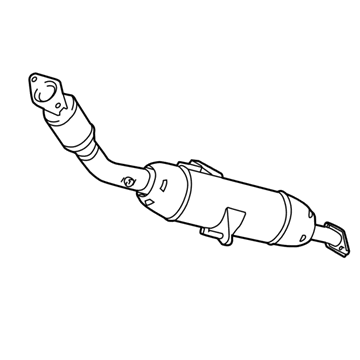

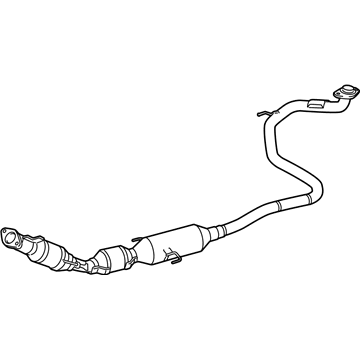

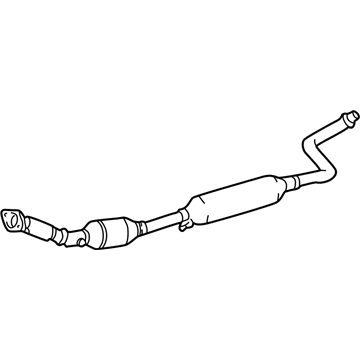

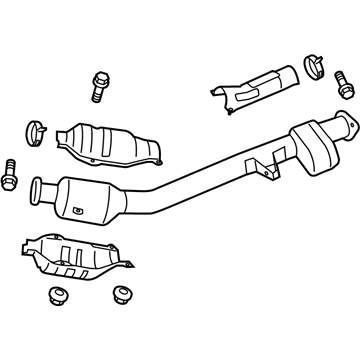

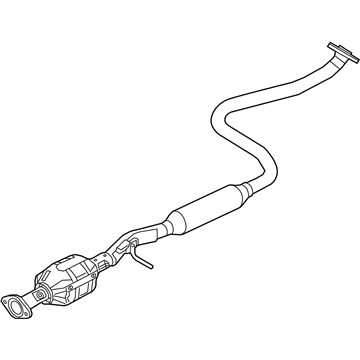

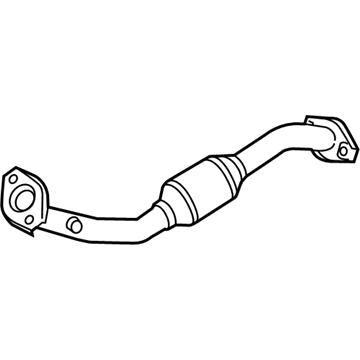

Scion Front Pipe

Part Number: 17410-37A50$1306.26 MSRP: $1753.38You Save: $447.12 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Scion Front Pipe

Part Number: 17410-37271$1525.88 MSRP: $2048.18You Save: $522.30 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Intermediate Pipe, Front; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Scion Front Pipe

Part Number: 17410-21572$1539.96 MSRP: $2067.07You Save: $527.11 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe

- Replaces: 17410-21571, 17410-21570

Scion Front Pipe

Part Number: 17410-21441$1515.55 MSRP: $2034.32You Save: $518.77 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Crossover Pipe, Front; Catalytic Converter; Exhaust Pipe; Converter & Pipe

- Position: Front

- Replaces: 17410-21440

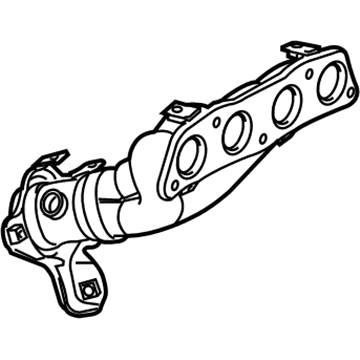

Scion Exhaust Manifold

Part Number: 17141-0T200$192.68 MSRP: $275.10You Save: $82.42 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Exhaust

- Manufacturer Note: (L)

- Replaces: 17141-37230, 17141-0T080

Scion Exhaust Manifold

Part Number: 25051-47080$388.27 MSRP: $483.92You Save: $95.65 (20%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Converter Sub-Assembly; Manifold; Converter Sub-Assembly, Exhaust Manifold

Scion Exhaust Manifold

Part Number: 25051-36180$337.95 MSRP: $410.37You Save: $72.42 (18%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Converter Sub-Assembly; Manifold Converter; Manifold; Converter Sub-Assembly, Exhaust Manifold

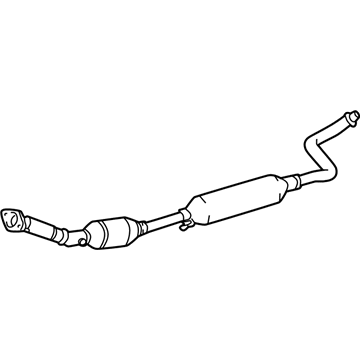

Scion Intermediate Pipe, Front

Part Number: SU003-06248$442.35 MSRP: $552.21You Save: $109.86 (20%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly Center-Exhaust, R; Catalytic Converter, Rear; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front; Catalytic Converter

- Position: Front

- Replaces: SU003-01131

Scion Catalytic Converter

Part Number: 25051-WB001$1639.13 MSRP: $2042.92You Save: $403.79 (20%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Converter Sub-Assembly; Catalytic Converter with Integrated Exhaust Manifold; Exhaust Manifold; Manifold W/Converter; Converter Sub-Assembly, Exhaust Manifold

Scion Exhaust Manifold

Part Number: 25051-28350$585.42 MSRP: $729.64You Save: $144.22 (20%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Converter Sub-Assembly; Catalytic Converter with Integrated Exhaust Manifold; Manifold Converter; Manifold; Converter Sub-Assembly, Exhaust Manifold

Scion Front Pipe

Part Number: 17410-WB002$892.17 MSRP: $1197.55You Save: $305.38 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

- Replaces: 17410-WB001

Scion Front Pipe

Part Number: 17410-47200$793.69 MSRP: $1065.37You Save: $271.68 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Scion Front Pipe

Part Number: 17410-37270$1253.60 MSRP: $1682.69You Save: $429.09 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Scion Exhaust Manifold, Front

Part Number: SU003-01134$594.24 MSRP: $809.90You Save: $215.66 (27%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Complete-Exhaust, Front; Catalytic Converter, Front; Preconverter; Manifold, Exhaust; Catalytic Converter

- Position: Front

Scion Catalytic Converter

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Scion produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Scion Catalytic Converter? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Scion Catalytic Converter filters the poisonous exhaust into clean air and keeps the engine energetic. The brand sat out of conservatism in showroom practices, retailed aggressive compact cars with virtual Scion City tie-ins, guerrilla concert tours and secret Release Series drops that hinted exclusivity, but never raised prices above a part-time paycheck. Scion regarded its offerings as a series of test laboratories, developing one-price menus over oddly dressed bodies, and then letting online forums help them make adjustments quicker than many companies could arrange focus groups. With its badge still present, Scion disappeared in 2016, but the parent companies still think that authenticity, short production, and easy customization appeal to young drivers more than slick advertisements do. The cars made Scion still get hailed by fans as the automobiles showed how affordable metal can spur pride, meet-ups and the mod culture without taking six-year loans. The Catalytic Converter uses a stainless shell and a platinum-palladium-rhodium honeycomb that is densely packed with super-hot gases directing them through enormous reactive surface, transforming the hydrocarbons, carbon monoxide and nitrogen oxides into much safer products without resulting in power-absorbing backpressure. Since backpressure is reduced by the Catalytic Converter, the engine has its way and maintains good mileage with traffic jams or with an interstate. Ceramics that are heat resistant allow the Catalytic Converter to shake off vibration, salt and violent temperature swings to be applied over long service. Making the Catalytic Converter replacement when warning codes appear and tailpipe tests remain legal around the country.

Scion Catalytic Converter Parts and Q&A

- Q: How to install the Catalytic Converter sub-assembly on Scion xB?A:Install the No. 2 exhaust manifold heat insulator first using 2 bolts that should attain 12 Nm (122 kgf-cm, 9 ft-lbf) of torque. After mounding the 4 bolts of the No. 1 manifold converter insulator it should be torqued to 12 Nm (122 kgf-cm, 9 ft-lbf). The exhaust manifold installation requires the use of new gaskets for nuts which must be tightened in the given sequence with a torquing value of 37 Nm (377 kgf-cm, 27 ft-lbf). After bolting the manifold stay using a nut and torquing it to 44 Nm (449 kgf-cm, 33 ft-lbf) you must install the No. 2 manifold stay using the same bolt and nut procedure and torquing force of 44 Nm (449 kgf-cm, 33 ft-lbf). Mount the front exhaust pipe by applying 4 bolts and installing two required compression springs. The procedure begins with sensor installation for the air fuel ratio followed by application of the No. 1 exhaust manifold insulator followed by exhaust gas leak inspection before the No. 1 engine under cover installation.