×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2009 Toyota Tundra Exhaust Pipe

Exhaust Tail Pipe- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Exhaust Pipes found

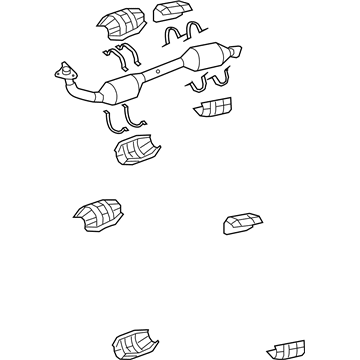

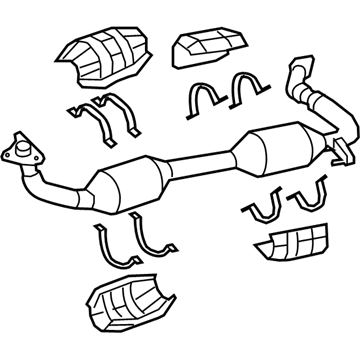

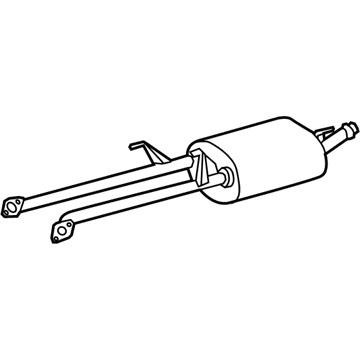

2009 Toyota Tundra Front Pipe

Part Number: 17410-0S070$1589.67 MSRP: $2133.80You Save: $544.13 (26%)Product Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter, Right; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

- Part Name Code: 17410

- Item Weight: 13.10 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-0S070

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

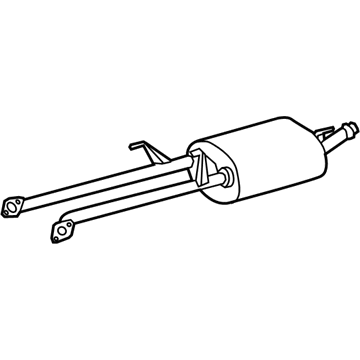

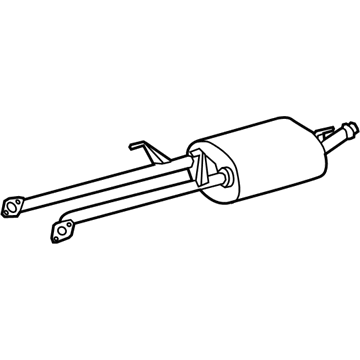

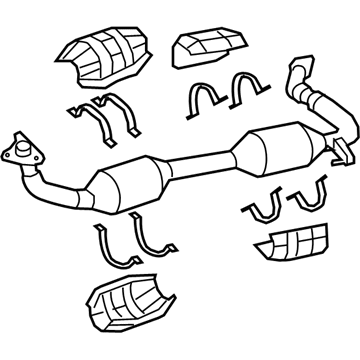

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0S022$532.08 MSRP: $714.20You Save: $182.12 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Muffler Assembly; Direct-Fit Exhaust; System Kit; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Manufacturer Note: MEXICO SPEC

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.20 Pounds

- Item Dimensions: 50.9 x 20.2 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0S022

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

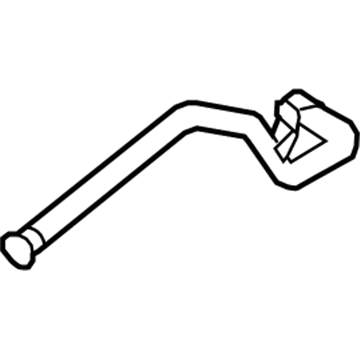

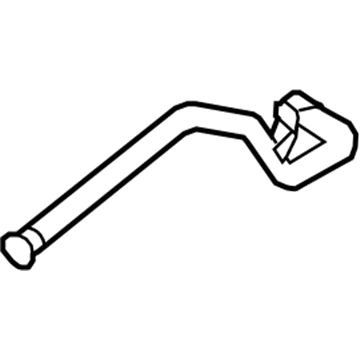

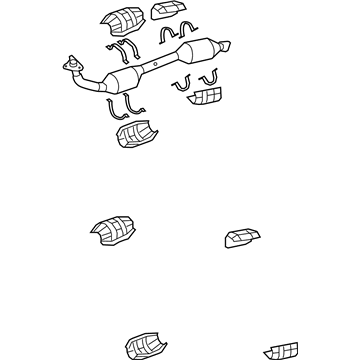

2009 Toyota Tundra Tail Pipe

Part Number: 17430-0F010$255.59 MSRP: $334.25You Save: $78.66 (24%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Tail; Exhaust Tail Pipe; Exhaust Pipe; Direct-Fit Exhaust; Exhaust System Kit; Tailpipe; Pipe Assembly, Exhaust, Tail

- Part Name Code: 17430

- Item Weight: 10.30 Pounds

- Item Dimensions: 43.6 x 12.5 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17430-0F010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

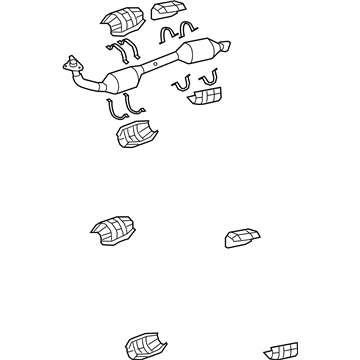

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0P110$2798.10 MSRP: $3755.87You Save: $957.77 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Part Name Code: 17450B

- Item Weight: 14.90 Pounds

- Item Dimensions: 39.6 x 13.7 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0P110

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0S140$1846.75 MSRP: $2478.87You Save: $632.12 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter, Left; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Replaces: 17450-0S011, 17450-0S010

- Part Name Code: 17450B

- Item Weight: 6.30 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0S140

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0S200$1432.59 MSRP: $1922.94You Save: $490.35 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Replaces: 17450-0S021, 17450-0S170, 17450-0S020

- Part Name Code: 17450B

- Item Weight: 14.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0S200

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0S190$1432.59 MSRP: $1922.94You Save: $490.35 (26%)Product Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Replaces: 17450-0S030, 17450-0S160, 17450-0S031

- Part Name Code: 17450B

- Item Weight: 16.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0S190

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0F050$710.16 MSRP: $953.24You Save: $243.08 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Muffler; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 16.80 Pounds

- Item Dimensions: 52.4 x 19.6 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0F050

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Tail Pipe

Part Number: 17430-0S010$319.20 MSRP: $417.43You Save: $98.23 (24%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Tail; Exhaust Tail Pipe; Direct-Fit Exhaust; Exhaust System Kit; Exhaust Pipe; Tailpipe; Pipe Assembly, Exhaust, Tail

- Part Name Code: 17430

- Item Weight: 10.20 Pounds

- Item Dimensions: 43.6 x 12.5 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17430-0S010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0P120$2244.68 MSRP: $3013.01You Save: $768.33 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Part Name Code: 17450B

- Item Weight: 11.00 Pounds

- Item Dimensions: 40.8 x 14.4 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0P120

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe

Part Number: 17410-0P170$2183.50 MSRP: $2930.90You Save: $747.40 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

- Part Name Code: 17410

- Item Weight: 11.20 Pounds

- Item Dimensions: 47.7 x 18.0 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-0P170

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0F120$1849.58 MSRP: $2482.68You Save: $633.10 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter, Left; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Part Name Code: 17450B

- Item Weight: 11.20 Pounds

- Item Dimensions: 40.8 x 14.4 x 8.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0F120

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe, Driver Side

Part Number: 17450-0F130$1987.60 MSRP: $2667.94You Save: $680.34 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front Driver Side

- Part Name Code: 17450B

- Item Weight: 11.00 Pounds

- Item Dimensions: 40.0 x 14.4 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-0F130

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Front Pipe

Part Number: 17410-0F090$1934.48 MSRP: $2596.64You Save: $662.16 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter, Right; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

- Part Name Code: 17410

- Item Weight: 11.00 Pounds

- Item Dimensions: 48.6 x 17.7 x 9.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-0F090

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0F041$661.47 MSRP: $887.88You Save: $226.41 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Muffler Assembly; Direct-Fit Exhaust; System Kit; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Position: Center

- Replaces: 17420-0F040

- Part Name Code: 17420

- Item Weight: 16.90 Pounds

- Item Dimensions: 52.4 x 19.8 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0F041

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0S030$659.42 MSRP: $885.14You Save: $225.72 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Muffler; Exhaust Muffler Assembly; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 16.30 Pounds

- Item Dimensions: 50.9 x 19.6 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0S030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0S010$610.85 MSRP: $819.93You Save: $209.08 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Muffler; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.10 Pounds

- Item Dimensions: 50.4 x 19.5 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0S010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Muffler & Pipe, Center

Part Number: 17420-0F030$485.20 MSRP: $651.28You Save: $166.08 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Muffler; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 16.80 Pounds

- Item Dimensions: 51.4 x 19.8 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0F030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Pipe Assembly, Exhaust; Exhaust Muffler; Exhaust Pipe; Tail Pipe; Pipe Assembly, Exhaust, Center; Muffler

- Position: Center

- Part Name Code: 17420

- Item Weight: 16.30 Pounds

- Item Dimensions: 51.9 x 19.6 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0F031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Tundra Exhaust Pipe

Looking for affordable OEM 2009 Toyota Tundra Exhaust Pipe? Explore our comprehensive catalogue of genuine 2009 Toyota Tundra Exhaust Pipe. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2009 Toyota Tundra Exhaust Pipe Parts Q&A

- Q: How to Remove the Exhaust Pipe in a Regular Cab Standard Deck on 2009 Toyota Tundra?A: Protective gloves and cool exhaust pipe conditions are necessary before attempting to remove the 1GR-FE engine exhaust pipe found in the Regular Cab Standard Deck vehicle. You need to start by taking off the bolting the clamp from the tailpipe assembly which allows you to detach the tailpipe from its position on the exhaust pipe support. The center exhaust pipe assembly needs to be separated through the removal of 4 bolts while detaching its connections to 3 exhaust pipe supports. The front No. 3 exhaust pipe sub-assembly removal begins when two bolts are unfastened and the exhaust pipe support connection is completed. Detach the front No. 2 exhaust pipe by unconnecting both air fuel ratio sensor and heated oxygen sensor connectors as well as removing the 3 retaining nuts. Disconnection of the front exhaust pipe assembly starts with removing 3 nuts after detaching 2 heated oxygen sensor wire clamps and separating the air fuel ratio sensor connector and heated oxygen sensor connector. According to their individual procedures remove Bank 1 Sensor 1 and Bank 2 Sensor 1 air fuel ratio sensors together with Bank 1 Sensor 2 and Bank 2 Sensor 2 heated oxygen sensors.