×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2009 Toyota Land Cruiser Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Exhaust Manifolds found

2009 Toyota Land Cruiser Exhaust Manifold, Driver Side

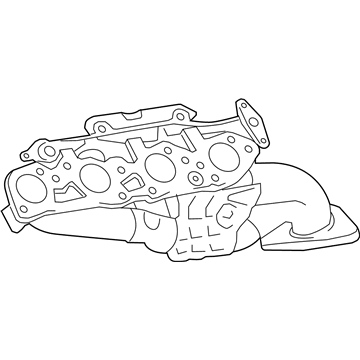

Part Number: 17150-38010$357.29 MSRP: $523.60You Save: $166.31 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Exhaust Manifold, Left; Manifold Assembly, Exhaust, Driver Side

- Position: Driver Side

- Part Name Code: 17150

- Item Weight: 11.50 Pounds

- Item Dimensions: 16.5 x 13.5 x 7.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17150-38010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Land Cruiser Manifold Assembly, Exhaust, Passenger Side

Part Number: 17140-38010$357.29 MSRP: $523.60You Save: $166.31 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Exhaust Manifold

- Position: Passenger Side

- Part Name Code: 17140

- Item Weight: 11.70 Pounds

- Item Dimensions: 16.2 x 13.1 x 7.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17140-38010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota Land Cruiser Exhaust Manifold

Looking for affordable OEM 2009 Toyota Land Cruiser Exhaust Manifold? Explore our comprehensive catalogue of genuine 2009 Toyota Land Cruiser Exhaust Manifold. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2009 Toyota Land Cruiser Exhaust Manifold Parts Q&A

- Q: How to install the exhaust manifold on 2009 Toyota Land Cruiser?A: The first step to install the exhaust manifold involves placing a new gasket on the cylinder head followed by placing another gasket on the No. 2 air tube. Both gaskets need to have their tab faces toward the engine front and their claws facing the tube side. The exhaust manifold needs to be attached with the A marked nuts and 8 new nuts while all other unlabeled nuts receive uniform tightening before torquing the A marked nuts to 10 Nm (102 kgf-cm, 7 ft-lbf) and the remaining nuts to 21 Nm (214 kgf-cm, 15 ft-lbf). The installation of the insulator to the exhaust manifold requires 2 nuts which should be torqued to 10 Nm (102 kgf-cm, 7 ft-lbf). The No. 1 exhaust manifold heat insulator should be installed using 3 bolts that need a torque setting of 10 Nm (102 kgf-cm, 7 ft-lbf). Tighten the two bolts on the No. 1 manifold stay following the order requirement to 40 Nm (408 kgf-cm, 30 ft-lbf) before removing them. For the exhaust manifold sub-assembly LH place the gasket tab facing towards the engine rear and apply the same nut tightening sequence as before. Weld the No. 2 exhaust manifold heat insulator in place using three bolfwith 10 Nm (102 kgf-cm, 7 ft-lbf) torque and mount the No. 2 manifold stay with two bolts fastened to 40 Nm (408 kgf-cm, 30 ft-lbf) torque. The propeller shaft heat insulator needs installation with two bolts tightened to 16 Nm (160 kgf-cm, 12 ft-lbf). The installation order should include front exhaust pipe assembly while also including the front No. 2 exhaust pipe assembly with center exhaust pipe assembly before installing the tailpipe assembly. Then install the engine oil level dipstick guide before conducting leakage tests on the exhaust system and conducting any necessary tightening and replacing any faulty parts. Using specified clips, finish the installation sequence by putting front fender apron seals on both sides. These installation steps cover the No. 1 engine under cover sub-assembly together with the front fender splash shield sub-assemblies (LH and RH) and the No. 2 engine under cover.