×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2008 Toyota Prius A/C Compressor

Air Conditioning Compressor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 A/C Compressor found

2008 Toyota Prius Compressor

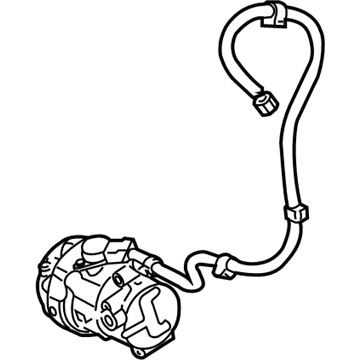

Part Number: 88370-47010$551.01 MSRP: $808.72You Save: $257.71 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor Assembly, With Pulley; A/C Compressor; Compressor Assembly, W/Motor

- Part Name Code: 88370

- Item Weight: 11.10 Pounds

- Item Dimensions: 13.5 x 9.5 x 9.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 88370-47010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2008 Toyota Prius A/C Compressor

Looking for affordable OEM 2008 Toyota Prius A/C Compressor? Explore our comprehensive catalogue of genuine 2008 Toyota Prius A/C Compressor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2008 Toyota Prius A/C Compressor Parts Q&A

- Q: How to install the A/C Compressor on 2008 Toyota Prius?A: The initial step for electric inverter compressor installation involves inspecting the compressor oil through a helium gas discharge procedure from the service valve followed by accurate oil removal per the formula (100 + 15 cc) - (remaining oil in the removed compressor assembly). Take necessary safety measures while handling the cooler installation process to prevent oil contamination that can interrupt refrigerant operations and create abnormal vibration issues. Check all leaks to determine the amount of ND-OIL 11 required for maintaining motor insulation performance when the compressor contains little remaining oil. Begin by tightening two compressor bolts only then proceed to achieve 25 Nm (255 kgf-cm, 18 ft-lbf) torque on all bolts starting with the specified sequence and finish with securing the remaining bolt at the same torque value. Secure the 3 wire harness clamps while connecting the wire harness using gloves with insulation protection and lock the green-colored lock. Install a fresh O-ring together with ND-OIL 11 lubrication, apply it to both an electric inverter compressor fitting surface and a new O-ring then secure the suction hose with a bolt that reaches 9.8 Nm (100 kgf/cm, 87 in-lbf). Apply the oil to the discharge hose again then put on the O-ring followed by bolting the hose at identical torque settings. Clients need to install the service plug grip while connecting the cable to the negative battery terminal and carry out an initial procedure that certain systems demand after restoring the battery connection. The last installation steps involve installing the deck floor box rear and rear No. 2 floor board while charging refrigerant then warming the compressor before conducting refrigerant leak tests.