×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2008 Toyota Camry Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Timing Chains found

2008 Toyota Camry Timing Chain

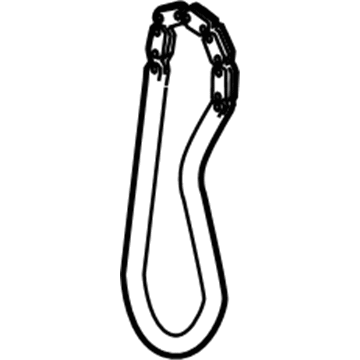

Part Number: 13507-28010$89.46 MSRP: $125.57You Save: $36.11 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly, Oil; Engine Timing Chain; Chain; Chain Sub-Assembly

- Replaces: 13507-0H020

- Part Name Code: 13507

- Item Weight: 0.70 Pounds

- Item Dimensions: 2.6 x 2.4 x 0.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13507-28010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

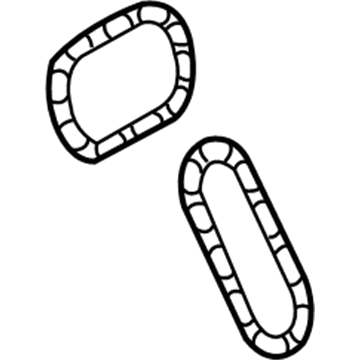

2008 Toyota Camry Timing Chain

Part Number: 13507-0P010$73.58 MSRP: $103.28You Save: $29.70 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly; Engine Timing Chain; Secondary Chain

- Replaces: 13507-31020

- Part Name Code: 13507

- Item Weight: 1.40 Pounds

- Item Dimensions: 2.7 x 2.4 x 0.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 13507-0P010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

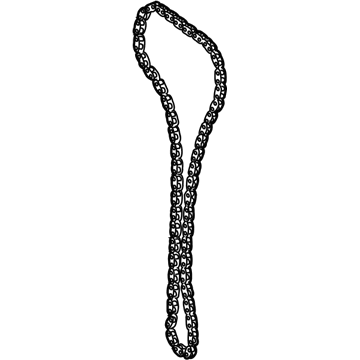

2008 Toyota Camry Timing Chain

Part Number: 13506-0H011$268.87 MSRP: $383.89You Save: $115.02 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly, Timing; Engine Timing Chain; Chain Sub-Assembly

- Replaces: 13506-28020, 13506-0H031, 13506-28010, 13506-28011, 13506-28021, 13506-0H010

- Part Name Code: 13506

- Item Weight: 1.20 Pounds

- Item Dimensions: 6.8 x 3.4 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13506-0H011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

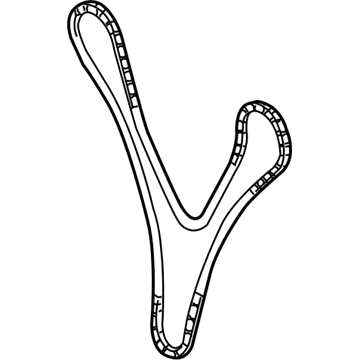

2008 Toyota Camry Timing Chain

Part Number: 13506-0P011$240.91 MSRP: $343.96You Save: $103.05 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly; Engine Timing Chain

- Manufacturer Note: (L)

- Replaces: 13506-31031, 13506-31020, 13506-0P010

- Part Name Code: 13506

- Item Weight: 1.40 Pounds

- Item Dimensions: 6.5 x 3.4 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13506-0P011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2008 Toyota Camry Timing Chain

Looking for affordable OEM 2008 Toyota Camry Timing Chain? Explore our comprehensive catalogue of genuine 2008 Toyota Camry Timing Chain. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2008 Toyota Camry Timing Chain Parts Q&A

- Q: How to install the No. 2 Timing Chain sub-assembly and complete the assembly process on 2008 Toyota Camry?A: The installation requires positioning the crankshaft key into its left horizontal orientation while rotating the drive shaft for upward facing alignment of yellow mark links with all gear timing marks. First position the crankshaft key at the left horizontal alignment then place the oil pump drive shaft sprocket on its gear while winding the chain along its toothed surface before securing it using the nut. From the inside of the adjusting hole, position the damper spring before adding the chain tensioner plate with a bolt that requires 12 Nm (122 kgf-cm, 9 ft-lbf) of torque. The alignment between the oil pump groove and the oil pump drive shaft sprocket adjusting hole must be achieved before installing a 4mm-diameter bar and tightening the nut to 30 Nm (301 kgf-cm, 22 ft-lbf). Position the crankshaft at a 90-degree angle clockwise point and bring the crankshaft key to the top position during the crankshaft timing sprocket installation. Fasten the No. 1 chain vibration damper by using two bolts which need to be torqued to 9.0 Nm (92 kgf-cm, 80 in-lbf). Set the No. 1 cylinder to TDC using compression while using a wrench to position camshafts at the correct timing alignment compared to the marks on No. 1 and No. 2 bearing caps and adjust the crankshaft key orientation to face upward. Set the gold or pink mark link of the chain opposite the crankshaft timing sprocket timing mark. Afterward install the crankshaft timing sprocket through repeated blows with Special Service Tool: 09309-37010 and a hammer. The first step is to position the gold or yellow link directly above each timing mark on the camshaft timing gear and sprocket before fastening the chain tensioner slipper and timing chain guide. Both elements require a torque of 19 Nm (194 kgf-cm, 14 ft-lbf) for the tensioner slipper whereas the guide needs 9.0 Nm (92 kgf-cm, 80 in-lbf). The timing chain case oil seal and timing chain cover sub-assembly should be installed after the No.1 crankshaft position sensor plate facing forward direction with "F" mark visible. Installation of the V-ribbed belt tensioner assembly spring type requires the bolt tightening first followed by nut tightening up to 60 Nm (607 kgf-cm, 44 ft-lbf) while ensuring the pin replacement is done correctly. The non-spring type tensioner installation requires the same 60 Nm (607 kgf-cm, 44 ft-lbf) torque when tightening the bolt and nut together. Use 3 bolts to fasten the engine mounting bracket RH while torquing them to 54 Nm (551 kgf-cm, 40 ft-lbf). Then raise the engine to mount the engine mounting insulator RH using 4 nuts, which need proper torque values of 95 Nm (969 kgf-cm, 70 ft-lbf) for Nut A and 87 Nm (888 kgf-cm, 64 ft-lbf) for Nut B. The steering gear return tube clamps require installation onto the frame via 2 bolts at 8.0 Nm (80 kgf-cm, 69 in-lbf) torque. Additionally, install the engine mounting insulator FR with a bolt at 87 Nm (888 kgf-cm, 64 ft-lbf) torque. The manual transmission requires installation of the engine lateral control rod with one bolt while torquing to 89 Nm (910 kgf-cm, 66 ft-lbf). Use a continuous section of seal packing (Diameter 3.0 to 4.0 mm (0.118 to 0.157 in.)) to coat the oil pan sub-assembly contact areas before installing it to the cylinder block. Tighten the 12 bolts and 2 nuts in a sequence to 9.0 Nm (92 kgf-cm, 80 in-lbf). You should install the crank position sensor and crankshaft pulley with the No. 1 chain tensioner assembly while releasing the ratchet pawl and completely pushing the plunger before tightening to 9.0 Nm (92 kgf-cm, 80 in-lbf). The cylinder head cover sub-assembly requires seal packing application before its installation with 8 bolts along with 2 nuts where Bolt A receives 11 Nm (112 kgf-cm, 8 ft-lbf) torque and Bolt B gets 14 Nm (143 kgf-cm, 10 ft-lbf) torque and the nut receives 11 Nm (112 kgf-cm, 8 ft-lbf) torque. The installation of the engine wires starts with torquing their 2 bolts to 8.4 Nm (86 kgf-cm, 74 in-lbf). This is followed by attaching the No. 2 ventilation hose and ventilation hose, then using 4 bolts to secure the ignition coil assembly at 9.0 Nm (92 kgf-cm, 80 in-lbf) and finally connecting the vane pump assembly. The procedural order includes installing the generator assembly followed by the V-ribbed belt and proceeded with the No. 2 engine mounting bracket RH then engine moving control rod sub-assembly and finishing with the No. 2 engine mounting stay RH. The front exhaust pipe receives installation followed by engine oil addition then the negative battery terminal cable connection and leak checks on engine oil and exhaust gas and ignition timing verification and assembly of the front fender apron seal together with engine under cover LH and engine under cover RH parts and front wheel RH and No. 1 engine cover sub-assembly.