×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2005 Scion xA Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rack And Pinion found

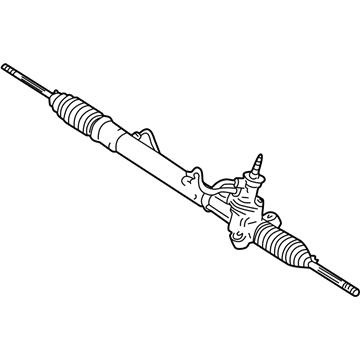

2005 Scion xA Steering Gear

Part Number: 44200-52340$610.09 MSRP: $894.08You Save: $283.99 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rack and Pinion Assembly; Steering Gearbox; Gear Assembly; Steering Gear Assembly; Link Assembly, Power Steering

- Part Name Code: 44200

- Item Weight: 13.70 Pounds

- Item Dimensions: 50.2 x 10.4 x 6.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44200-52340

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Scion xA Rack And Pinion

Looking for affordable OEM 2005 Scion xA Rack And Pinion? Explore our comprehensive catalogue of genuine 2005 Scion xA Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2005 Scion xA Rack And Pinion Parts Q&A

- Q: How to Overhaul the Rack and Pinion in a Power Steering Link Assembly on 2005 Scion xA?A: The first step of power steering link assembly overhaul requires you to apply either power steering fluid or molybdenum disulfide lithium base grease to designated components. Start by taking off the front wiper arms on both right and left sides and the hood to cowl top seal, cowl top ventilator louvers from right and left sides, windshield wiper motor with link assembly and cowl panel sub-assembly. After inspecting the center front wheel proceed to remove the steering column hole cover plate and separate the steering sliding yoke sub-assembly by using a seat belt to fix the steering wheel from rotating and by marking the sliding yoke and intermediate shaft and loosening the bolt. Clip A should be disengaged to sever the first steering column hole cover sub-assembly while you drain power steering fluid from the hood sub-assembly. The front wheel assembly needs removal followed by the separation of tie rod end sub-assemblies (left and right) using tools 09620-62011 and 09628-62011. Afterward remove engine under covers on both sides. You must disconnect the pressure feed tube assembly while using Special Service Tool: 09023-12701 for unclipping and hose return and then separate the front suspension arm sub-assemblies (lower No.1 LH and RH) using Special Service Tool: 09628-00011. The engine assembly requires suspension from the floor using two No.1 engine hangers with the following part numbers: No.1 engine hanger: 12281-21010 and Bolt: 91642-81025. Use two No.1 engine hangers (12281-21010 with bolt 91642-81025 torqued to 40Nm) to suspend the engine assembly while performing the following tasks. Remove the front suspension crossmember sub-assembly by unbolt its components and reinforce it with a transmission jack. I will take off the power steering rack housing heat insulator together with steering column hole cover sub-assembly No.1 and steering intermediate shaft while marking the steering link assembly and intermediate shaft before I proceed with removal. Mark both the power steering rack and the bracket No.2 before removing their bolts and nuts along with bracket No.2, grommet No.2, and the entire assembly while properly torquing the bolt when using the attached nut. Use Special Service Tool: 09023-38201 to remove the steering right turn pressure tube along with its O-rings before performing the same procedure for the left turn pressure tube. After setting the power steering rack with Special Service Tool: 09612-00012 users should detach the tie rod end sub-assemblies (LH and RH) by marking then loosening the lock nut. Apply caution when removing clips and clamps from the rack and pinion boot before you extract No.1 and No.2 boot and rack and pinion end subassembly by using Special Service Tool: 09922-10010. The rack guide and power steering control valve require disassembly before you remove their bolts and replace the gasket after marking both the rack housing and control valve housing. The rack steering piston requires removal of its end stopper through needle nose plier manipulation before the power steering rack with rack bush extraction using Special Service Tool: 09950-70010 (09951-07200) and a press tool followed by complete removal of the rack bush combined with an oil seal utilizing a Special Service Tool: 09612-24014 (09613-22011). Detach the piston ring along with the O-ring from the rack steering piston yet avoid harming the grooves during removal. Check the power steering rack for maximum runout at 0.1 mm while evaluating its teeth wear and damage. Measure the torque settings of both LH and RH tie rod end sub-assemblies. The new power steering rack housing oil seal must have its proper positioning checked before installing the rack steering piston ring and adjusting the power steering fluid levels accurately.