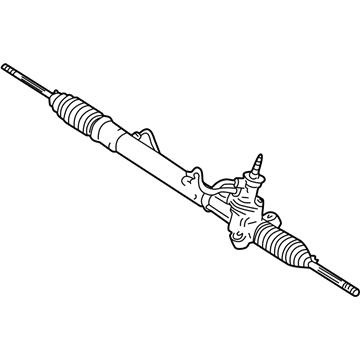

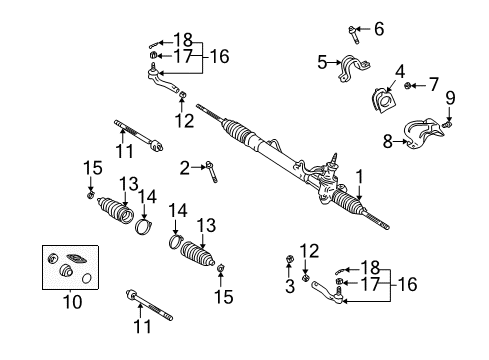

OEM Toyota part with Part Number 44200-52340 Steering Gear known as Toyota Rack And Pinion component provides maximum durability and optimal performance. The certified Toyota dealership components feature a warranty protection for 12-month, 12,000-mile usage. The use of OEM part 44200-52340 Steering Gear enables maintenance standards that match the original factory installation quality. The specific item serves the following model series: 2003-2005 Toyota Echo.

Genuine Toyota offers this high-quality Rack and Pinion Assembly; Steering Gearbox under Manufacturer Part Number 44200-52340 for use. This product identification code consists of 44200 which proves its manufacturer as Toyota. This component features dimensions of 50.2 x 10.4 x 6.6 inches and weighs 13.70 Pounds. This component 4420052340 is specially constructed for vehicle fitting requirements within the Direct Replacement classification. This product is also known as Gear Assembly; Steering Gear Assembly; Link Assembly, Power Steering. Each vehicle requires the component which has an identified SKU of 44200-52340. The factory-warranty from Toyota guarantees continuous reliable operation and high performance for this part 44200-52340. The Shipping Policy and Return Policy pages provide full details about shipping procedures and return instructions.

OEM parts have no match as far as quality is concerned. They are thoroughly quality controlled and are made to Toyota factory specifications. All these eliminate the faults and flaws. And that is why you can be worry-free because they guarantee an outstanding lifespan and perfect matching. We offer very many different OEM components at competitive prices at ToyotaPartsNow.com. We offer an entire product line of all authentic Toyota products, with a manufacturer warranty as an assurance. Customer satisfaction is also part of our priorities and we offer no-hassles returns and fast shipping of all our components.