×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota Celica Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Axle Shafts found

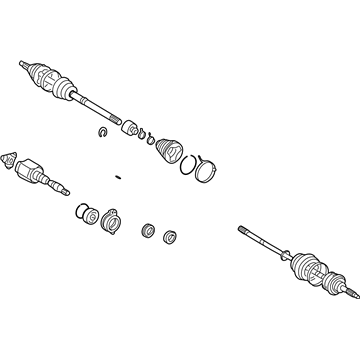

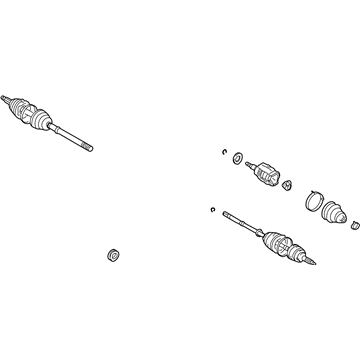

2004 Toyota Celica Shaft & Joint Assembly

Part Number: 43470-29725$237.85 MSRP: $339.59You Save: $101.74 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Drive Outboard; Axle Shaft; CV Joint; Outer Joint Assembly

- Condition: New

- SKU: 43470-29725

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

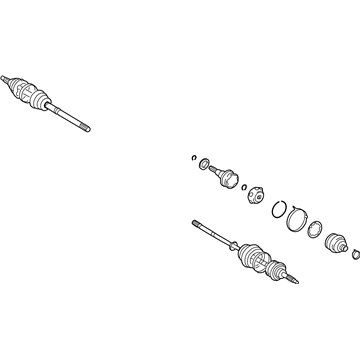

2004 Toyota Celica Axle Assembly, Passenger Side

Part Number: 43410-20800$468.03 MSRP: $685.90You Save: $217.87 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; CV Axle Assembly

- Manufacturer Note: W(ABS)

- Position: Passenger Side

- Part Name Code: 43410

- Item Weight: 27.50 Pounds

- Item Dimensions: 43.3 x 5.5 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20800

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Passenger Side

Part Number: 43410-20760$450.95 MSRP: $660.87You Save: $209.92 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side

- Position: Passenger Side

- Part Name Code: 43410

- Item Weight: 25.30 Pounds

- Item Dimensions: 43.7 x 5.6 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20760

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Passenger Side

Part Number: 43410-20771$450.60 MSRP: $660.35You Save: $209.75 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; CV Axle Assembly

- Position: Passenger Side

- Replaces: 43410-20770

- Part Name Code: 43410

- Item Weight: 19.20 Pounds

- Item Dimensions: 43.7 x 5.5 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20771

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Passenger Side

Part Number: 43410-20781$449.71 MSRP: $659.06You Save: $209.35 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; CV Axle Assembly

- Manufacturer Note: W(ABS)

- Position: Passenger Side

- Replaces: 43410-20780

- Part Name Code: 43410

- Item Weight: 21.70 Pounds

- Item Dimensions: 42.8 x 5.4 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20781

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Passenger Side

Part Number: 43410-20600$449.01 MSRP: $658.03You Save: $209.02 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side

- Manufacturer Note: W(ABS)

- Position: Passenger Side

- Part Name Code: 43410

- Item Weight: 26.80 Pounds

- Item Dimensions: 42.8 x 5.4 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20600

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

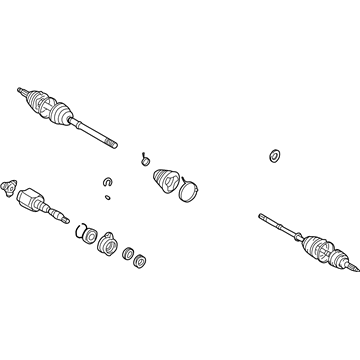

2004 Toyota Celica Axle Assembly, Driver Side

Part Number: 43420-20540$417.20 MSRP: $611.42You Save: $194.22 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Position: Driver Side

- Part Name Code: 43420

- Item Weight: 14.60 Pounds

- Item Dimensions: 29.2 x 7.5 x 6.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20540

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Driver Side

Part Number: 43420-20571$397.36 MSRP: $582.35You Save: $184.99 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Position: Driver Side

- Replaces: 43420-20570

- Part Name Code: 43420

- Item Weight: 14.60 Pounds

- Item Dimensions: 31.3 x 5.1 x 5.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20571

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

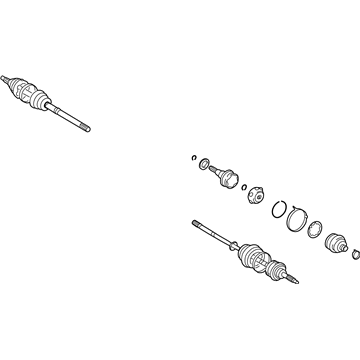

2004 Toyota Celica Axle Assembly, Driver Side

Part Number: 43420-20550$397.36 MSRP: $582.35You Save: $184.99 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; Axle Shaft; Shaft Assembly, Front Drive, Driver Side

- Position: Driver Side

- Part Name Code: 43420

- Item Weight: 14.10 Pounds

- Item Dimensions: 28.9 x 7.5 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20550

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Driver Side

Part Number: 43420-20581$396.85 MSRP: $581.60You Save: $184.75 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Manufacturer Note: W(ABS)

- Position: Driver Side

- Replaces: 43420-20580

- Part Name Code: 43420

- Item Weight: 14.30 Pounds

- Item Dimensions: 30.4 x 5.3 x 5.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20581

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Assembly, Driver Side

Part Number: 43420-20560$396.72 MSRP: $581.40You Save: $184.68 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; Axle Shaft; Shaft Assembly, Front Drive, Driver Side

- Manufacturer Note: W(ABS)

- Position: Driver Side

- Part Name Code: 43420

- Item Weight: 27.30 Pounds

- Item Dimensions: 31.0 x 5.3 x 5.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20560

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; CV Axle Assembly

- Position: Passenger Side

- Part Name Code: 43410

- Item Weight: 27.30 Pounds

- Item Dimensions: 43.7 x 5.6 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-20790

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Manufacturer Note: W(ABS)

- Position: Driver Side

- Part Name Code: 43420

- Item Weight: 26.80 Pounds

- Item Dimensions: 29.8 x 5.2 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-20590

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Celica Axle Shaft

Looking for affordable OEM 2004 Toyota Celica Axle Shaft? Explore our comprehensive catalogue of genuine 2004 Toyota Celica Axle Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota Celica Axle Shaft Parts Q&A

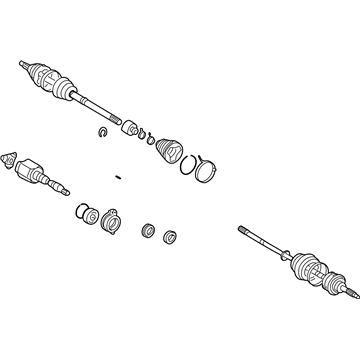

- Q: How to disassemble and reassemble the axle shaft for the engines on 2004 Toyota Celica?A: When servicing the 1Z-FE engine (M/T) or 2Z-GE engine one must check the outboard joint for play and inspect that the inboard joint moves freely while looking for damage on the boots. The process requires using a screwdriver and side cutter on boot clamps to remove them before beginning dynamic damper clamp disassembly. Move the inboard joint boot towards the outboard joint while keeping your matchmarks undamaged and then take off the snap ring before unfastening the inboard joint shaft. Disassemble the outboard joint shaft through the process of matchmarking and successive removal of six balls followed by sliding the cage then using a snap ring expander and brass bar to take out the inner race and cage. The repair process for the dynamic damper requires removing the damper clamp and inboard and outboard joint boots together with inboard joint clamps but the outboard joint remains intact. To check the drive shaft of the 1Z-FE engine (A/T) you should use the same procedures to remove boot clamps then slide the inboard joint boot and place matchmarks before using a snap ring expander and brass bar to extract the inboard joint shaft and tripod. Remove the inboard and outboard joint boots as well as clamps from the transmission yet keep the outboard joint whole. Use SST 09950-00020 along with a snap ring expander for the LH inboard joint shaft of 1Z-FE engine (M/T) and 2Z-GE engine and the transaxle side dust cover for RH side with a press and remove the center bearing by taking off the outside snap ring using a snap ring expander then press the center bearing case to expose the straight pin which requires a pin punch for removal. Install the inboard joint shaft after placing new dust cover on with a press and new outer snap ring by using a snap ring expander followed by center bearing installation via pin punch and press together with SST 09950-60010 (09951-00650), 09950-70010 (09951-07150). A steel plate along with a press enables installation of the transaxle side dust cover. Remember to use new temporary boot and clamp installations on the 1Z-FE engine (A/T) and you should tape the outboard joint shaft spline with vinyl tape. Insert the tripod after properly positioning its matchmarks then tap it before adding the new snap ring. After installation of the inboard joint shaft follow by matching the marks while performing a temporary boot installation. The boot clamps should be assembled by placing the boots inside the shaft grooves while avoiding stretch then securing the inboard joint clamps and locking the outboard joint clamps. Adjust the boot clamp clearance by tightening the large clamp with SST 09521-24010 and using SST 09240-00020 to reach 0.8 mm or less. Complete the small clamp with the same procedure. The assembly process for the outboard joint shaft begins with dynamic damper and clamp installation for 1Z-FE engine (M/T) and 2ZZ-GE engine but requires vinyl tape wrapping of the spline before cage placement and matchmark alignment and inner race tapping and new snap ring addition. Grass the outboard boot together with the matching joint grease until it reaches 115 to 135 g before placing the inboard shaft and matching the marks with a new snap ring. Follow the earlier described techniques to install boot clamps correctly while setting the M/T dynamic damper distance to 155.0 ± 2.0 mm before locking the clamp. Finally, check the drive shaft.