×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Sequoia Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Shock Absorbers found

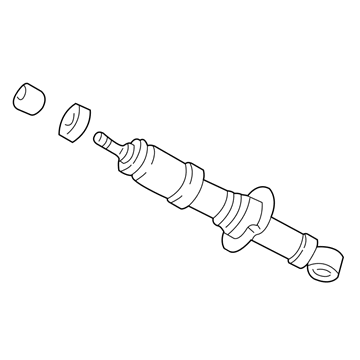

2003 Toyota Sequoia Shock Absorber, Front

Part Number: 48510-A9170$151.68 MSRP: $214.72You Save: $63.04 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber, Shock, Front; Suspension Kit; Strut Assembly; Shock Set; Complete Strut; Strut; Absorber Assembly, Shock, Front Passenger Side; Absorber Assembly, Shock, Front Driver Side; Shock

- Manufacturer Note: MARK=48510-AF040

- Position: Front

- Item Weight: 6.90 Pounds

- Item Dimensions: 27.1 x 8.5 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48510-A9170

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

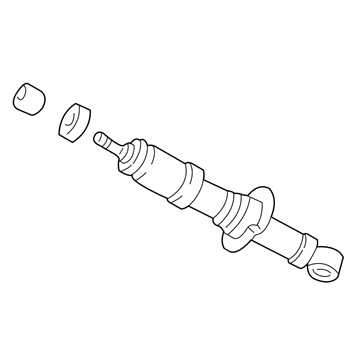

2003 Toyota Sequoia Shock Absorber, Front

Part Number: 48510-A9180$147.45 MSRP: $208.74You Save: $61.29 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock, Front; Suspension Kit; Strut Assembly; Shock Set; Complete Strut; Strut; Absorber Assembly, Shock, Front Passenger Side; Absorber Assembly, Shock, Front Driver Side; Shock

- Manufacturer Note: MARK=48510-AF050

- Position: Front

- Item Weight: 9.70 Pounds

- Item Dimensions: 26.6 x 8.2 x 7.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48510-A9180

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

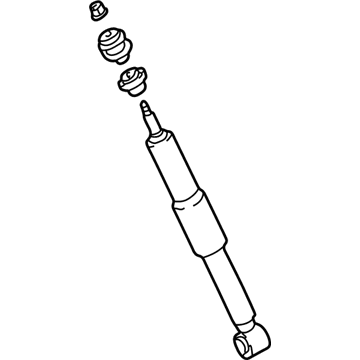

2003 Toyota Sequoia Shock Absorber

Part Number: 48530-A9180$92.77 MSRP: $130.23You Save: $37.46 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Shock Absorber; Suspension Kit; Strut Assembly; Shock Set; Strut Kit; Shock; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-AF021

- Item Weight: 7.10 Pounds

- Item Dimensions: 26.1 x 6.5 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-A9180

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Sequoia Shock Absorber

Part Number: 48530-A9170$96.45 MSRP: $135.38You Save: $38.93 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Shock Absorber; Suspension Kit; Strut Assembly; Shock Set; Strut Kit; Shock; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-AF011

- Item Weight: 1.90 Pounds

- Item Dimensions: 25.6 x 6.6 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-A9170

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Sequoia Shock Absorber

Part Number: 48530-80104$82.58 MSRP: $115.92You Save: $33.34 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Shock Absorber; Suspension Kit; Strut Assembly; Shock Set; Strut Kit; Shock; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-34010

- Item Weight: 5.40 Pounds

- Item Dimensions: 25.8 x 6.6 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-80104

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Sequoia Shock Absorber

Part Number: 48530-80105$82.82 MSRP: $116.25You Save: $33.43 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Shock Absorber; Suspension Kit; Strut Assembly; Shock Set; Strut Kit; Shock; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-34020

- Item Weight: 6.90 Pounds

- Item Dimensions: 25.8 x 6.6 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-80105

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Sequoia Shock Absorber

Looking for affordable OEM 2003 Toyota Sequoia Shock Absorber? Explore our comprehensive catalogue of genuine 2003 Toyota Sequoia Shock Absorber. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Sequoia Shock Absorber Parts Q&A

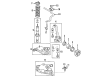

- Q: How to service and repair the rear shock absorber with coil spring on 2003 Toyota Sequoia?A: First service or repair the rear shock absorber with coil spring by taking away both rear wheels while tightening them to 110 Nm (1,150 kgf-cm, 83 ft. lbs.). Raise the rear axle housing with a jack while performing the operation. Service the shock absorber of the normal type by removing the housing bolt that requires 87 Nm (887 kgf-cm, 64 ft. lbs.) torque before doing the same procedure to the opposite side. You must first hold the piston rod before you proceed to remove the nut followed by the 2 retainers and shock absorber and cushion at 58 Nm (591 kgf-cm, 43 ft. lbs.) torque. At this point, you need to extract the 2 retainers and cushion from the shock absorber. When removing auto-leveler parts you must make sure the shock absorber reaches its full stretched position. Detach the shock absorber from the axle housing in a similar manner before proceeding with the other side. When holding the piston rod you should remove the nut, retainer, cushion, shock absorber using 58 Nm (591 kgf-cm, 43 ft. lbs. torque) and subsequently uninstall the retainer and cushion from the shock absorber. Use a torque wrench to remove the two LH and RH stabilizer bar links nuts to 69 Nm (704 kgf-cm) before disconnecting the lateral control rod by taking out nut and washer and bolt to a torque of 140 Nm (1,428 kgf-cm). Re-torque these components on stabilized suspension. Lift the axle housing slowly to protect cables while removing coil spring components along with follow spring and insulator. Ensure correct positioning of the coil spring end before final installation. Check for abnormal resistance and irregular sounds in the normal type shock absorber by compressively moving its rod before deciding to replace it if abnormal conditions exist. The disposal process begins with stretching the shock absorber rod completely before drilling a hole into the cylinder for the normal type shock absorber users while strictly guarding against loose chip materials. The procedure for the auto leveler type requires drilling a hole through the shaded part of the cylinder while following pressure changes from the high to low chamber and wearing protective goggles and covering the absorber. The bushing replacement process for the normal type requires Special Service Tools: 09710-14013 (09710-10061), 09710-28012 (09710-17031), 09950-70010 (09951-17100) as well as a press to achieve successful removal and installation of new bushings. You should conduct the installation steps exactly opposite to the removal order.