×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Highlander Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Shock Absorbers found

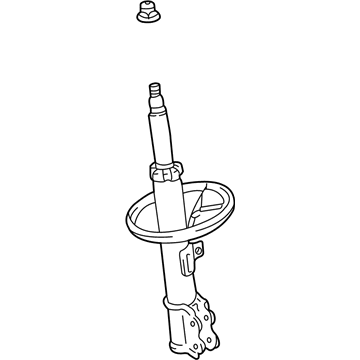

2003 Toyota Highlander Strut Assembly, Front Passenger Side

Part Number: 48510-49655$157.91 MSRP: $223.53You Save: $65.62 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Set, Front Right-Hand; Suspension Strut, Front Right; Shock Absorber; Strut

- Position: Front Passenger Side

- Replaces: 48510-49285

- Item Weight: 9.80 Pounds

- Item Dimensions: 27.1 x 8.4 x 7.6 inches

- Condition: New

- SKU: 48510-49655

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Strut, Rear Driver Side

Part Number: 48540-49125$161.67 MSRP: $228.87You Save: $67.20 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Left Suspension Strut; Complete Strut Kit; Shock Absorber; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48540-48080

- Position: Rear Driver Side

- Part Name Code: 48540

- Item Weight: 11.90 Pounds

- Item Dimensions: 26.9 x 7.1 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48540-49125

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Strut, Rear Passenger Side

Part Number: 48530-49195$161.67 MSRP: $228.87You Save: $67.20 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Right Suspension Strut; Complete Strut Kit; Shock Absorber; Absorber Assembly, Shock, Rear Passenger Side

- Manufacturer Note: MARK 48530-48080

- Position: Rear Passenger Side

- Part Name Code: 48530

- Item Weight: 12.70 Pounds

- Item Dimensions: 26.9 x 6.9 x 6.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-49195

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

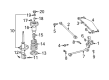

2003 Toyota Highlander Strut Assembly, Front Driver Side

Part Number: 48520-49715$154.97 MSRP: $219.38You Save: $64.41 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Set, Front Left-Hand; Suspension Strut, Front Left; Shock Absorber; Strut

- Position: Front Driver Side

- Replaces: 48520-49395

- Item Weight: 9.30 Pounds

- Item Dimensions: 26.9 x 8.5 x 7.4 inches

- Condition: New

- SKU: 48520-49715

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Strut, Rear Driver Side

Part Number: 48540-49145$175.06 MSRP: $247.83You Save: $72.77 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Left Suspension Strut; Complete Strut Kit; Shock Absorber; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48540-48100

- Position: Rear Driver Side

- Part Name Code: 48540

- Item Weight: 6.90 Pounds

- Item Dimensions: 26.1 x 6.6 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48540-49145

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Strut, Rear Passenger Side

Part Number: 48530-49215$175.06 MSRP: $247.83You Save: $72.77 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Rear Right Suspension Strut; Complete Strut Kit; Shock Absorber; Absorber Assembly, Shock, Rear Passenger Side

- Manufacturer Note: MARK 48530-48100

- Position: Rear Passenger Side

- Part Name Code: 48530

- Item Weight: 6.50 Pounds

- Item Dimensions: 25.6 x 6.6 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-49215

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Shock Absorber

Looking for affordable OEM 2003 Toyota Highlander Shock Absorber? Explore our comprehensive catalogue of genuine 2003 Toyota Highlander Shock Absorber. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Highlander Shock Absorber Parts Q&A

- Q: How to install a Shock Absorber in a rear strut assembly on 2003 Toyota Highlander?A: The procedure to replace the rear strut starts with wheel removal before you disconnect the stabilizer bar link assembly by unscrewing the nut to separate the stabilizer bar link from the shock absorber while using a 5 mm hexagon (hex) wrench to stabilize the stud if the ball joint turns with the nut. To begin the replacement of the shock absorber proceed with removing two bolts from 2WD models and disconnecting the flexible hose and speed sensor wire for both 2WD and 4WD models. Begin shock absorber lower bolt loosening before supporting the axle carrier with a jack tool then eliminating the small cap followed by center suspension support nut loosening. The service procedure involves removing first the 3 suspension support nuts then lowering the rear axle carrier to finally extract the shock absorber with coil spring by uninstalling its bottom 2 nuts and bolts. Put two nuts along with a bolt onto the shock absorber bracket at the bottom section before clamping it in a vise then use Special Service Tool: 09727-30021 to clamp the coil spring yet use extreme caution by not applying power with an impact wrench to safeguard the tool. Start by removing the nut and collar followed by suspension support and then take out coil spring and spring bumper and lower insulator. The examination of the rear shock absorber assembly requires rod compression together with shock absorber rod extension to identify any unusual sounds or resistant behavior which would trigger a replacement. For coil spring installation onto the shock absorber start by positioning the spring bumper and lower insulator. After using Special Service Tool 09727-30021 to compress the coil spring, place the coil spring in position, position the suspension support exactly aligned with the shock absorber lower bracket, install the collar to the piston rod and temporarily fasten a new nut before removing the Special Service Tool. Finish with one more check of the suspension support direction. The procedure starts by installing the shock absorber with coil spring along with three nuts until torque reaches 39 Nm (400 kgf-cm, 29 ft. lbs.). Afterwards, add the shock absorber with coil spring, two bolts and nuts while torquing to 255 Nm (2,600 kgf-cm, 188 ft. lbs.). For 2WD models, install the flexible hose and ABS speed sensor wire harness with 2 bolts, torquing the flexible hose to 19 Nm (194 kgf-cm, 14 ft. lbs.) and the ABS speed sensor wire harness to 5.0 Nm (51 kgf-cm, 41 inch lbs.); for 4WD models, install the flexible hose and ABS speed sensor with 3 bolts, torquing the flexible hose to 19 Nm (194 kgf-cm, 14 ft. lbs.), the ABS speed sensor wire harness to 5.4 Nm (55 kgf-cm, 48 inch lbs.), and the ABS speed sensor to 19.5 Nm (198 kgf-cm, 14 inch lbs.). Rest the suspension support by torquing the center nut to 49 Nm (500 kgf-cm, 36 ft. lbs.). After installing the cap replace the rear stabilizer link to the shock absorber with its nut tightened to 39 Nm (400 kgf-cm, 29 ft. lbs.). Deployment of a hexagon wrench (5 mm) on the stud is necessary for proper installation. You need to install the rear wheel by applying torques of 103 Nm (1,050 kgf-cm, 76 ft. lbs.) before checking the rear wheel alignment. The disposal process requires extending the shock absorber rod before drilling a hole in the cylinder to release the gas content while guarding against flying metal fragments during this operation.