×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Tacoma Sway Bar Kit

Stabilizer Sway Bar Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Sway Bar Kits found

2002 Toyota Tacoma Stabilizer Bar, Front

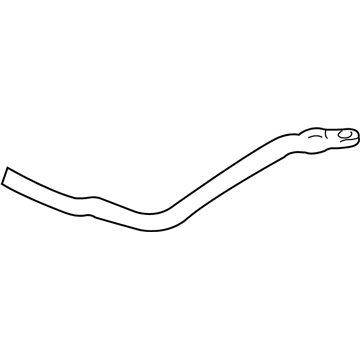

Part Number: 48811-AD040$165.60 MSRP: $234.43You Save: $68.83 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bar, Stabilizer, Front; Suspension Stabilizer Bar, Front; Sway Bar

- Position: Front

- Part Name Code: 48811

- Item Weight: 8.00 Pounds

- Item Dimensions: 44.2 x 12.0 x 4.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48811-AD040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Tacoma Stabilizer Bar, Front

Part Number: 48811-04110$145.57 MSRP: $206.07You Save: $60.50 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bar, Stabilizer; Suspension Stabilizer Bar, Front; Sway Bar; Bar, Stabilizer, Front

- Position: Front

- Part Name Code: 48811

- Item Weight: 13.10 Pounds

- Item Dimensions: 55.7 x 13.7 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48811-04110

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Tacoma Stabilizer Bar, Front

Part Number: 48811-AD010$136.96 MSRP: $193.88You Save: $56.92 (30%)Product Specifications- Other Name: Bar, Stabilizer, Front; Suspension Stabilizer Bar, Front; Sway Bar

- Manufacturer Note: OFF ROAD PACKAGE

- Position: Front

- Part Name Code: 48811

- Item Weight: 7.50 Pounds

- Item Dimensions: 43.8 x 12.2 x 4.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48811-AD010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

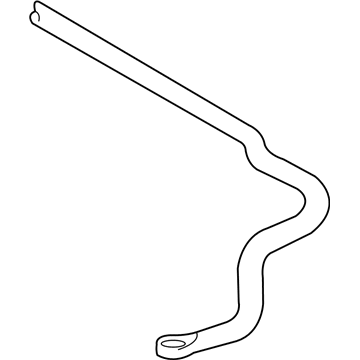

- Product Specifications

- Other Name: Bar, Stabilizer, Front; Suspension Stabilizer Bar, Front; Sway Bar

- Position: Front

- Part Name Code: 48811

- Item Weight: 8.10 Pounds

- Item Dimensions: 42.5 x 12.2 x 4.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48811-04090

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

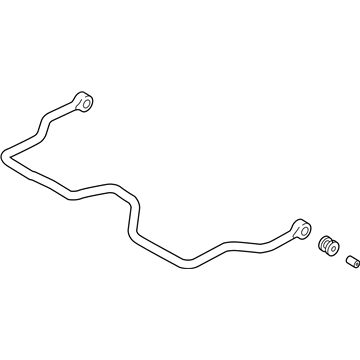

- Product Specifications

- Other Name: Bar Sub-Assembly, Rear Stabilizer; Suspension Stabilizer Bar, Rear; Sway Bar

- Position: Rear

- Part Name Code: 48805

- Item Weight: 5.10 Pounds

- Item Dimensions: 41.6 x 9.2 x 3.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48805-AD020

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Tacoma Sway Bar Kit

Looking for affordable OEM 2002 Toyota Tacoma Sway Bar Kit? Explore our comprehensive catalogue of genuine 2002 Toyota Tacoma Sway Bar Kit. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Tacoma Sway Bar Kit Parts Q&A

- Q: How to Service the Sway Bar Kit on 2002 Toyota Tacoma?A: Service the sway bar kit of RZN191L-TRPDKAB, RZN196L-CRPDKAB, PZN196L-PRPDKAB, VZN195L-CRPDKAB and VZN195L-PRPDKAB models in the following way: start by removing the front wheels and applying 110 Nm (1,150 kgf-cm, 83 ft. lbs.) torque. You can remove the sway bar links by unfastening the 2 nuts along with the link from the lower suspension arm and sway bar kit and tightening the nuts to 90 Nm (920 kgf-cm, 66 ft. lbs.). When the ball joint stud rotates along with the nut you should apply a hexagon wrench to grip the stud. Carry out the same procedure on the opposite wheel side. First remove the sway bar kit by unfastening the 4 bracket set bolts while detaching both the bar with cushions and brackets and apply a tightening torque of 25 Nm (260 kgf-cm, 19 ft. lbs.). The next step requires you to take off both sway bar brackets and cushions. During inspection of the link ball joint check the rotation condition by turning the ball joint stud five times in each direction before applying the nut. Apply a turning torque of 0.05 - 2.0 Nm (0.5 - 20 kgf-cm, 0.4 - 17 inch lbs.) while giving the nut continuous 1 turn every 2 - 4 seconds to acquire the torque reading on the 5th turn. The installation of both hardware and software follows the opposite sequence to which they were removed.