×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Land Cruiser Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Axle Shafts found

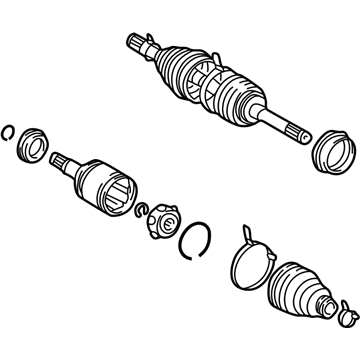

2002 Toyota Land Cruiser Axle Assembly, Front

Part Number: 43430-60040$372.28 MSRP: $572.11You Save: $199.83 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left, Front Right; Joint Kit, Drive Shaft; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Position: Front

- Item Weight: 33.30 Pounds

- Item Dimensions: 31.5 x 6.3 x 6.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43430-60040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

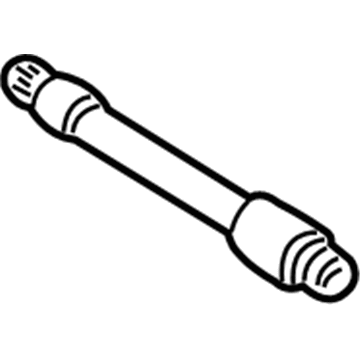

2002 Toyota Land Cruiser Axle Shaft, Driver Side

Part Number: 41337-60010$233.45 MSRP: $333.32You Save: $99.87 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft, Differential Side Gear Intermediate; Drive Axle Shaft, Front Right; Axle Shafts; Output Shaft; Shaft Sub-Assembly, Differential Side Gear, Driver Side

- Position: Driver Side

- Part Name Code: 41304V

- Item Weight: 7.20 Pounds

- Item Dimensions: 7.4 x 6.9 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41337-60010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Land Cruiser Shaft, Rear Axle, Driver Side

Part Number: 42302-60901$824.79 MSRP: $1208.74You Save: $383.95 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Sub-Assembly Rear Axle Right-Hand; Axle Shaft

- Position: Driver Side

- Part Name Code: 42312

- Item Weight: 15.60 Pounds

- Item Dimensions: 28.2 x 8.6 x 7.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42302-60901

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Land Cruiser Shaft, Rear Axle, Passenger Side

Part Number: 42301-60901$698.13 MSRP: $1023.11You Save: $324.98 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Sub-Assembly Rear Axle Right-Hand; Axle Shaft

- Position: Passenger Side

- Part Name Code: 42311L

- Item Weight: 15.20 Pounds

- Item Dimensions: 29.3 x 9.1 x 7.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42301-60901

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Land Cruiser Shaft, Rear Axle, Passenger Side

Part Number: 42301-60902$698.13 MSRP: $1023.11You Save: $324.98 (32%)Product Specifications- Other Name: Shaft Sub-Assembly Rear Axle Right-Hand; Axle Shaft

- Manufacturer Note: W(DIFFERENTIAL LOCK)

- Position: Passenger Side

- Part Name Code: 42311L

- Item Weight: 16.20 Pounds

- Item Dimensions: 29.6 x 8.9 x 8.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42301-60902

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Land Cruiser Axle Shaft

Looking for affordable OEM 2002 Toyota Land Cruiser Axle Shaft? Explore our comprehensive catalogue of genuine 2002 Toyota Land Cruiser Axle Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Land Cruiser Axle Shaft Parts Q&A

- Q: How to remove the axle shaft on 2002 Toyota Land Cruiser?A: The axle shaft removal begins by using a torque wrench to detach the front wheel to 131 Nm (1,340 kgf-cm, 97 ft. lbs.). The first step involves disconnecting the flexible hose from the steering knuckle using 28 Nm (290 kgf-cm, 21 ft. lbs.) torque before removing the 2 bolts and washers with 123 Nm (1,250 kgf-cm, 91 ft. lbs.) torque but always maintain a secure support for the brake caliper. You will remove the snap ring by using a combination of a screwdriver to tap the grease cap free from the flange with a hammer then following up with snap ring pliers to separate the snap ring. Unplug the ABS speed sensor and wire harness by taking off the bolts that require torques at 8.0 Nm (82 kgf-cm, 71 inch lbs.), 13 Nm (130 kgf-cm, 10 ft. lbs.) and 28 Nm (290 kgf-cm, 21 ft. lbs.). The procedure requires bolting removal from the 2 steering knuckle arm pieces applying 147 Nm (1,500 kgf-cm, 108 ft. lbs.) torque force and cleaning both threads and knuckle with toluene or trichloroethylene fluids then applying Part No. 08833-00070, Three Bond 1324 sealant to bolt threads. You need to disconnect the steering knuckle from the lower suspension arm by removing the cotter pin and nut with 159 Nm (1,625 kgf-cm, 117 ft. lbs.) torque and continuing to tighten the nut up to 60 degrees for misaligned cotter pin holes while using Special Service Tool: 09620-62011. The technician will detach the steering knuckle with axle hub by temporarily applying the lower suspension arm's nut then using a jack for support while removing the cotter pin and nut with 110 Nm of torque and further tightening up to a 60 degrees angle using tool 09628-62011. The drive shaft can be removed with a brass bar and hammer while maintaining boot and dust cover and oil seal integrity before using a screwdriver on the inboard joint tulip snap ring. You should apply MP grease on the oil seal lip before assembly while setting your new snap ring opening down and testing hand removal resistance of the drive shaft. The order of installation begins with steps that are opposite to uninstallation methods with a subsequent evaluation of the ABS speed sensor signal.