×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota MR2 Spyder Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Wheel Bearings found

2000 Toyota MR2 Spyder Wheel Bearing

Part Number: 90080-36136$58.54 MSRP: $81.49You Save: $22.95 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing, Radial Ball; Wheel Bearing, Front, Front Left, Front Right, Rear; Wheel Bearing Kit; Wheel Bearings; Front Wheel Bearing for Passenger & Driver Side Axle Hub.

- Replaces: 90363-40069, 90363-40066

- Item Weight: 2.00 Pounds

- Item Dimensions: 3.4 x 3.5 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 90080-36136

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

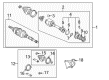

2000 Toyota MR2 Spyder Axle Support Bearing

Part Number: 90363-36004$36.67 MSRP: $51.05You Save: $14.38 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing, Radial Ball; CV Axle Shaft Carrier Bearing, Front, Rear; Wheel Bearing; Axle Bearing; Inner Shaft Bearing; Case Bearing; Bearing; Bearing (For Front Drive Shaft); Bearing(For Rear Drive Shaft)

- Item Weight: 1.10 Pounds

- Item Dimensions: 2.8 x 0.9 x 2.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 90363-36004

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

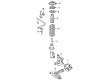

2000 Toyota MR2 Spyder Hub Assembly

Part Number: 43550-17010$303.47 MSRP: $433.29You Save: $129.82 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hub&Bearing Assembly; Front Wheel Bearing & Hub; Wheel Hub Repair Kit; Axle Bearing; Front Hub & Bearing; Hub Sub-Assembly, Front Axle, Passenger & Driver Side; Wheel Bearing Assembly.

- Item Weight: 6.70 Pounds

- Item Dimensions: 6.8 x 6.8 x 6.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43550-17010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota MR2 Spyder Wheel Bearing

Looking for affordable OEM 2000 Toyota MR2 Spyder Wheel Bearing? Explore our comprehensive catalogue of genuine 2000 Toyota MR2 Spyder Wheel Bearing. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota MR2 Spyder Wheel Bearing Parts Q&A

- Q: How to Service and Repair a Wheel Bearing on 2000 Toyota MR2 Spyder?A: You must remove the front wheel and fasten it at 103 Nm (1,050 kgf-cm, 76 ft. lbs.) before starting wheel bearing servicing and repair. You need to take out two bolts with a 109 Nm (1,112 kgf-cm, 80 ft. lbs.) torque from the brake caliper then disc before properly supporting the brake caliper. A dial indicator will reveal backlash and deviation data of the bearing and axle hub; bearings should be changed if backlash reaches 0.05 mm (0.0020 inch) or deviation crosses 0.07 mm (0.0028 inch). To remove the front axle hub, disconnect the ABS speed sensor and then unscrew all 4 bolts which require 56 Nm (571 kgf-cm) torque equivalent to 41 ft. lbs. Use a torques of 140 Nm (1,430 kgf-cm, 103 ft. lbs.) to loosen the 2 nuts on the lower shock absorber side while keeping bolts in place. The suspension stability becomes crucial before installing the nut because the torque strength requirement must be at least 98 Nm (1,000 kgf-cm, 72 ft. lbs.) but can be increased up to 60 degrees if the holes for a new cotter pin do not align. The lower suspension arm can be disconnected by using Special Service Tool: 09628-62011. The procedure to remove the tie rod end includes using Special Service Tool: 09610-20012 for nut tightening up to 60° when the holes for new cotter pins are not properly aligned while maintaining 49 Nm (500 kgf-cm, 36 ft. lbs.) torque. Install engine oil on the thread before placing the steering knuckle into position. The removal process involves taking out the 2 bolts and 2 nuts from the lower side of the shock absorber to finally detach the steering knuckle. Carry out installation by following the opposite sequence of disassembly steps and inspect the ABS speed sensor signal along with the rear wheel alignment after completion.