×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Corolla Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Wheel Bearings found

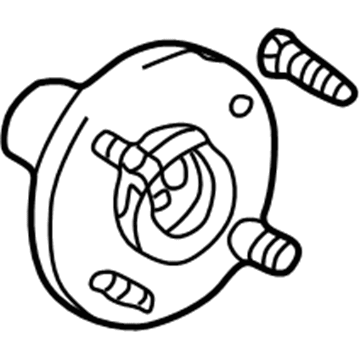

2000 Toyota Corolla Front Hub

Part Number: 43502-12090$144.04 MSRP: $203.91You Save: $59.87 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hub Sub-Assembly, Front Axle; Wheel Hub, Front; Wheel Hub Repair Kit; Wheel Hub Kit; Hub; Hub Sub-Assembly, Front Axle, Passenger Side; Hub Sub-Assembly, Front Axle, Driver Side; Wheel Hub

- Position: Front

- Item Weight: 4.70 Pounds

- Item Dimensions: 5.1 x 3.9 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43502-12090

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

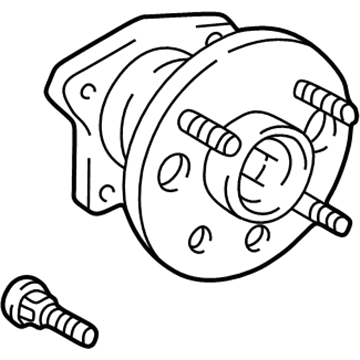

2000 Toyota Corolla Hub Assembly

Part Number: 42410-12090$361.83 MSRP: $530.26You Save: $168.43 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hub&Bearing Assembly; Rear Wheel Bearing and Hub Assembly; Wheel Hub Repair Kit; Axle Bearing.; Hub & Bearing; Rear Axle Assembly, Passenger & Driver Side; Wheel Bearing and Hub Assembly.

- Manufacturer Note: (J)

- Replaces: 42410-02020

- Item Weight: 8.50 Pounds

- Item Dimensions: 6.8 x 6.7 x 4.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42410-12090

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Corolla Hub Assembly, Rear

Part Number: 42450-02010$473.06 MSRP: $693.27You Save: $220.21 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hub&Bearing Assembly, Rear Axle; Wheel Bearing & Hub Assembly; Wheel Hub Repair Kit; Axle Bearing; Hub & Bearing; Rear Axle Assembly, Passenger & Driver Side; Wheel Bearing and Hub Assembly.

- Position: Rear

- Item Weight: 9.00 Pounds

- Item Dimensions: 6.6 x 6.9 x 6.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42450-02010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Bearing, Bca, 38, 72, K; Wheel Bearing, Front; Wheel Hub Repair Kit; Wheel Bearing Kit; Axle Bearing; Wheel Hub; Wheel Bearings; Front Wheel Bearing; Wheel Bearing & Hub; Bearing

- Position: Front

- Replaces: 90369-38016, 90369-38011, 90080-36040, 90369-38010, 90363-38006, 90080-36041, 90080-36063

- Item Weight: 1.40 Pounds

- Item Dimensions: 3.5 x 3.5 x 2.0 inches

- Condition: New

- SKU: 90363-38006-77

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Corolla Wheel Bearing

Looking for affordable OEM 2000 Toyota Corolla Wheel Bearing? Explore our comprehensive catalogue of genuine 2000 Toyota Corolla Wheel Bearing. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Corolla Wheel Bearing Parts Q&A

- Q: How to service and repair the wheel bearing on 2000 Toyota Corolla?A: You must start with removing the dust deflector using a screwdriver so you can begin wheel bearing service and repair. You can detach the lower ball joint after removing its cotter pin and nut and using Special Service Tool: 09628-62011 to remove the joint. Apply Special Service Tool: 09308-00010 on the inner oil seal and Utilize snap ring pliers to remove the snap ring from the threaded hole. Start with Special Service Tool: 09520-00031 (09520-00040, 09521-00010, 09521-00020) which enables you to remove the axle hub before extracting its inner races from inside and outer races from outside through Special Service Tool: 09950-40011 (09951-04020, 09952-04010, 09953-04030, 09954-04010, 09955-04061, 09957-04010, 09958-04011), 09950-60010, 09951-00360. Begin by removing the dust cover through T30 Torx wrench unscrewing of 3 bolts followed by applying Special Service Tool: 09308-00010 to extract the outer oil seal. Special Service Tools 09527-17011 along with 09950-60010 (09951-00650) and 09950-70010 (09951-07150) used with a press allow removal of the bearing from the steering knuckle by placing the inner race (outside) on the bearing. At reassembly time you need to install the bearing with Special Service Tool: 09950-60020 (09951-00710), 09950-70010 (09951-07150) operated by a press to eliminate the inner races from a new bearing. Proceed with installing the inner races into their proper positioning. Insert the outer oil seal by applying MP grease to its lip using Special Service Tool: 09316-60011 (09316-00011, 09316-00061), 09527-17011 with the assistance of a hammer. Secure the 3 dust cover bolts with a torx wrench T30 and tighten them to 8.3 Nm (85 kgf.cm, 74 inch lbs.). The installation process requires Special Service Tool: 09950-60010 (09951-00650), 09950-70010 (09951-07150) along with a press to avoid damaging the bearing during installation of the axle hub. With snap ring pliers install a new snap ring before installing the inner oil seal while using Special Service Tool: 09608-32010, 09950-70010 (09951-07150) and a hammer and applying MP grease to the oil seal's lip. The lower ball joint assembly requires torque at 124 Nm (1,260 kgf.cm, 91 ft. lbs.) then the technician should insert a new cotter pin while tightening the nut up to 60 degrees when holes are not aligned. To finish the installation, use Special Service Tools 09950-60020 (09951-00890) and 09950-70010 (09951-07150) together with a hammer which ensures proper alignment between the ABS speed sensor hole and steel knuckle hole.