×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tundra Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

38 Oxygen Sensors found

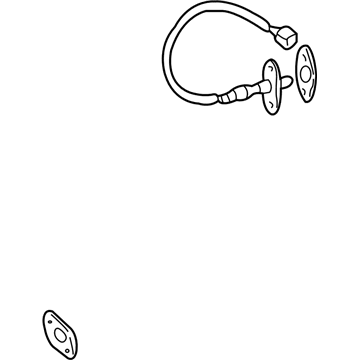

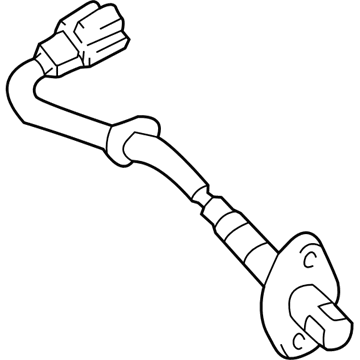

Toyota Tundra Oxygen Sensor, Passenger Side

Part Number: 89467-0C050$214.46 MSRP: $306.20You Save: $91.74 (30%)Ships in 1-2 Business Days

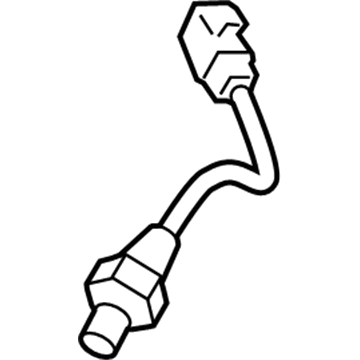

Toyota Tundra Oxygen Sensor, Rear

Part Number: 89465-09160$113.27 MSRP: $159.00You Save: $45.73 (29%)Ships in 1-3 Business Days

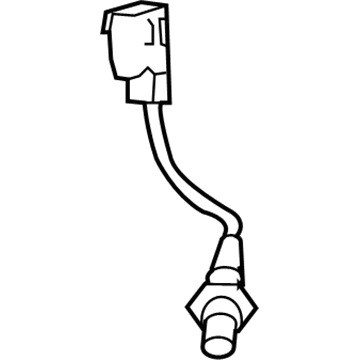

Toyota Tundra Oxygen Sensor, Rear Passenger Side

Part Number: 89465-09190$116.59 MSRP: $163.66You Save: $47.07 (29%)Ships in 1-2 Business Days

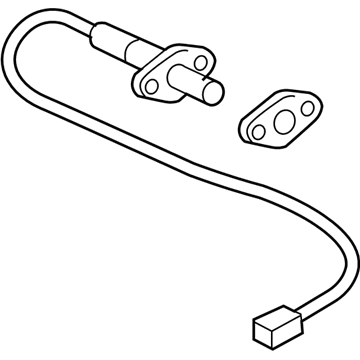

Toyota Tundra Oxygen Sensor, Front Passenger Side

Part Number: 89465-34140$132.53 MSRP: $187.61You Save: $55.08 (30%)Ships in 1-2 Business Days

Toyota Tundra Oxygen Sensor, Front Driver Side

Part Number: 89465-34150$132.53 MSRP: $187.61You Save: $55.08 (30%)Ships in 1-2 Business Days

Toyota Tundra Oxygen Sensor, Rear Passenger Side

Part Number: 89465-09390$113.04 MSRP: $158.66You Save: $45.62 (29%)Ships in 1-3 Business Days

Toyota Tundra Oxygen Sensor, Front Driver Side

Part Number: 89465-0C170$128.06 MSRP: $181.29You Save: $53.23 (30%)Ships in 1-2 Business Days

Toyota Tundra Oxygen Sensor, Rear

Part Number: 89465-09320$114.10 MSRP: $160.17You Save: $46.07 (29%)Ships in 1-2 Business Days

Toyota Tundra Oxygen Sensor, Rear Passenger Side

Part Number: 89465-09310$118.90 MSRP: $168.31You Save: $49.41 (30%)Ships in 1-3 Business Days

Toyota Tundra Oxygen Sensor, Rear Driver Side

Part Number: 89465-09380$113.04 MSRP: $158.66You Save: $45.62 (29%)Ships in 1-3 Business Days

Toyota Tundra Oxygen Sensor, Front Passenger Side

Part Number: 89465-04300$112.33 MSRP: $157.66You Save: $45.33 (29%)Ships in 1-2 Business DaysToyota Tundra Oxygen Sensor, Passenger Side

Part Number: 89467-0C030$198.74 MSRP: $283.75You Save: $85.01 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor, Front

Part Number: 89465-09220$113.27 MSRP: $159.00You Save: $45.73 (29%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor, Rear Passenger Side

Part Number: 89467-0C080$178.00 MSRP: $254.15You Save: $76.15 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor, Front Driver Side

Part Number: 89467-0C130$167.43 MSRP: $237.01You Save: $69.58 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor, Front Passenger Side

Part Number: 89467-0C140$155.09 MSRP: $219.54You Save: $64.45 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor

Part Number: 89467-0C100$158.26 MSRP: $224.04You Save: $65.78 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor, Rear Driver Side

Part Number: 89467-0C040$158.26 MSRP: $224.04You Save: $65.78 (30%)Ships in 1-3 Business DaysToyota Tundra Oxygen Sensor

Part Number: 89467-0C090$169.07 MSRP: $239.34You Save: $70.27 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 38 Results

Toyota Tundra Oxygen Sensor

Choose genuine Oxygen Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Oxygen Sensor for your Toyota Tundra? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tundra parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Oxygen Sensor in Toyota Tundra is used to determine the amounts of oxygen in the exhaust system so that the engine computer can control the air to fuel ration for efficient burning of fuel. This process also optimise the fuel consumption and reduce exhaust fumes. Bad oxygen sensor can cause problems such as a weak idle, difficult start, higher fuel consumption, adverse effects on the performance and emissions from improved car fuel systems. Usually mounted on the passenger side, downstream of the catalytic converter, a Tundra may have multiple sensors depending on its exhaust setup. Single exhaust models come with a pair of sensors while the dual exhaust systems will come with four. Different kinds of oxygen sensors include the zirconia and titania sorts, that operate in different ways. Zirconia sensors are common used for feedback in the form of current values to sustain the proper air fuel mixture; titania sensors modulate the resistance instead of the voltage.

Toyota Tundra Oxygen Sensor Parts and Q&A

- Q: How to remove the heated oxygen sensors on Toyota Tundra?A:The first step for heated oxygen sensor removal from the 1GR-FE engine control system requires disconnecting the cable from the negative terminal then allowing a minimum of 90 seconds after switch-off to record memory and settings. The technician must start by taking off the front No. 3 Exhaust Pipe sub-assembly for Regular Cab Standard Deck before proceeding to remove the front No. 2 exhaust pipe assembly for Regular Cab Standard Deck then moving on to the front No. 2 exhaust pipe assembly for all other configurations. Move on to the subsequent step by taking out the front exhaust pipe assembly. To remove heated oxygen sensors from Bank 1 Sensor 2 and Bank 2 Sensor 2 use Special Service Tool: 09224-00010.

- Q: How to install an Oxygen Sensor in the Air Fuel Ratio Sensor and Exhaust Pipe Assemblies on Toyota Tundra?A:The installation of Air Fuel Ratio Sensor for Bank 1 Sensor 1 requires use of Special Service Tool: 09224-00010 along with a torque of 40 Nm (408 kgf-cm, 30 ft-lbf) for the tool or 44 Nm (449 kgf-cm, 32 ft-lbf) for the toolless method. This process requires a torque wrench with a fulcrum length of 30 cm (11.8 in.) and a straight line connection. Bank 2 Sensor 1 demands that you proceed with the same installation process and torque values. To begin with achining the Front Exhaust Pipe Assembly requires installation of a new gasket followed by 3 new nut attachment at 54 Nm (551 kgf-cm, 40 ft-lbf) to join the exhaust pipe to the Exhaust Manifold RH before linking the exhaust pipe to the center exhaust pipe with 2 bolts at 48 Nm (489 kgf-cm, 35 ft-lbf) while completing both air fuel ratio sensor and heated oxygen sensor connector connections. The Front No. 2 Exhaust Pipe Assembly (except Regular Cab Standard Deck) requires the exhaust pipe attachment to the support followed by installation of a new gasket to the exhaust manifold LH with 3 new nuts tightened to 54 Nm (551 kgf-cm, 40 ft-lbf) and final attachment to the center exhaust pipe using 2 bolts at 48 Nm (489 kgf-cm, 35 ft-lbf). The air fuel ratio sensor and heated oxygen sensor connectors must then be connected. When working on the Front No. 2 Exhaust Pipe Assembly of the Regular Cab Standard Deck the technician should install the new gasket at the exhaust manifold LH location using 54 Nm (551 kgf-cm, 40 ft-lbf) torque while also connecting the air fuel ratio sensor and heated oxygen sensor connectors. The Front No. 3 Exhaust Pipe Sub-Assembly installation for Regular Cab Standard Deck includes new gaskets applied to both front No. 2 and No. 3 exhaust pipes which are then bolted to the exhaust pipe support through 4 bolts and 2 new nuts at 48 Nm (489 kgf-cm, 35 ft-lbf). After disconnecting the cable from the negative battery terminal it is crucial to note that some systems request initialization steps before reconnecting the cable.