×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Solara Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Brake Calipers found

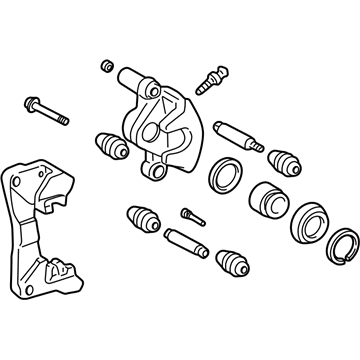

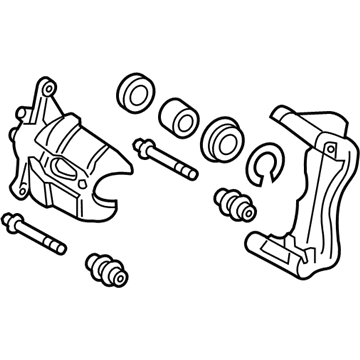

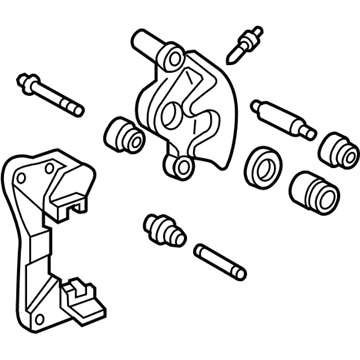

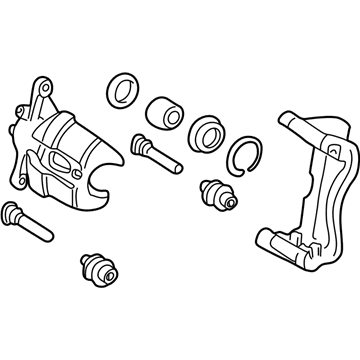

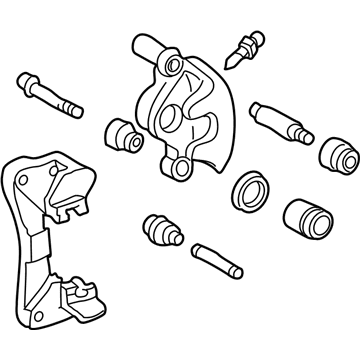

Toyota Solara Cylinder Assembly, Disc Brake, Rear Driver Side

Part Number: 47750-33100$240.56 MSRP: $343.46You Save: $102.90 (30%)Ships in 1-3 Business Days

Toyota Solara Caliper, Driver Side

Part Number: 47750-08030$247.32 MSRP: $353.11You Save: $105.79 (30%)Ships in 1-3 Business Days

Toyota Solara Caliper, Rear Driver Side

Part Number: 47750-06090$213.77 MSRP: $305.21You Save: $91.44 (30%)Ships in 1-3 Business Days

Toyota Solara Cylinder Assembly, Rear Disc Brake, Passenger Side

Part Number: 47730-33100$240.56 MSRP: $343.46You Save: $102.90 (30%)Ships in 1-3 Business Days

Toyota Solara Caliper, Passenger Side

Part Number: 47730-08030$247.32 MSRP: $353.11You Save: $105.79 (30%)Ships in 1-2 Business Days

Toyota Solara Caliper, Passenger Side

Part Number: 47730-06090$213.77 MSRP: $305.21You Save: $91.44 (30%)Ships in 1-3 Business DaysToyota Solara Cylinder Assembly, Disc

Part Number: 47750-06040-84$70.52 MSRP: $97.41You Save: $26.89 (28%)Ships in 1-3 Business DaysToyota Solara Cylinder Assembly, Disc

Part Number: 47730-06040-84$70.52 MSRP: $97.41You Save: $26.89 (28%)Ships in 1-3 Business DaysToyota Solara Caliper, Rear Driver Side

Part Number: 47750-06060$235.83 MSRP: $336.71You Save: $100.88 (30%)Ships in 1-3 Business Days

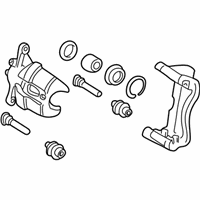

Toyota Solara Brake Caliper

Choose genuine Brake Caliper that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Brake Caliper for your Toyota Solara? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Solara parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Solara Brake Caliper Parts and Q&A

- Q: How to service and repair the brake caliper on Toyota Solara?A:Starting brake caliper repairs requires first removing the rear wheel and then fastening the disc temporarily using the 3 hub nuts. Separate the flexible hose after removing its union bolt with two gaskets from the caliper while placing all draining brake fluid into a collection container. The service starts by removal of the installation bolt so the caliper can be taken off the torque plate before extracting both the anti-squeal shims and brake pads and pad support plates. Crank the main pin installation bolt and pull out the main pin from its slot. The starting step involves mounting the main pin along with its installation bolt before tightening it to 26Nm (270 kgf-cm, 20 ft. lbs.). Position the 4 pad support plates and the 2 pads with anti-squeal shims on their respective positions but avoid contamination of friction surfaces by oil or grease. The installation bolt should be used to attach the caliper to the torque plate while torquing it to 20 Nm (200 kgf-cm, 14 ft. lbs.). Before attachment of the flexible hose to the caliper install the union bolt together with its gaskets and create a torque of 29 Nm (300 kgf-cm, 21 ft. lbs.). Also verify that the flexible hose lock remains secure on its location. Filling the brake reservoir with fluid should be followed by bleeding the brake system before checking for any fluid leakage. To complete the process install the rear wheel by torquing the hub nuts to 1,050 kgf-cm (76 foot pounds and 103 Newton meters).