×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Sequoia Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Exhaust Manifolds found

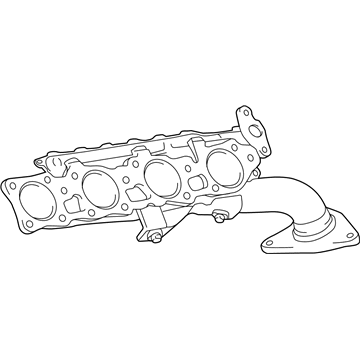

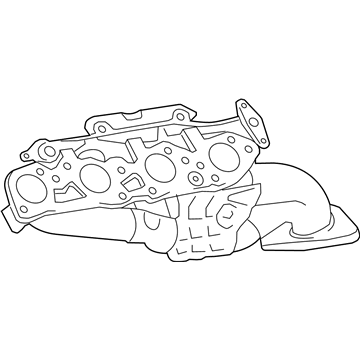

Toyota Sequoia Exhaust Manifold, Driver Side

Part Number: 17150-38040$353.09 MSRP: $517.46You Save: $164.37 (32%)Ships in 1-3 Business Days

Toyota Sequoia Exhaust Manifold, Driver Side

Part Number: 17105-50210$333.64 MSRP: $476.37You Save: $142.73 (30%)Ships in 1-3 Business Days

Toyota Sequoia Exhaust Manifold, Driver Side

Part Number: 17105-50190$333.64 MSRP: $476.37You Save: $142.73 (30%)Ships in 1-3 Business Days

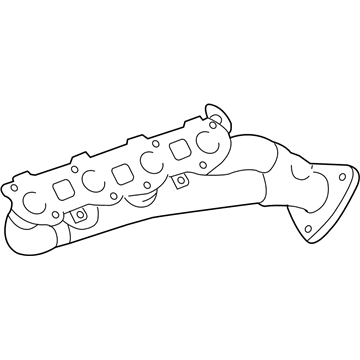

Toyota Sequoia Exhaust Manifold, Passenger Side

Part Number: 17104-50220$333.64 MSRP: $476.37You Save: $142.73 (30%)Ships in 1-3 Business Days

Toyota Sequoia Exhaust Manifold, Passenger Side

Part Number: 17104-50200$356.49 MSRP: $522.44You Save: $165.95 (32%)Ships in 1-2 Business Days

Toyota Sequoia Exhaust Manifold, Passenger Side

Part Number: 17104-50151$356.49 MSRP: $522.44You Save: $165.95 (32%)Ships in 1-2 Business Days

Toyota Sequoia Exhaust Manifold, Driver Side

Part Number: 17105-38011$477.14 MSRP: $699.26You Save: $222.12 (32%)Ships in 1-3 Business DaysToyota Sequoia Exhaust Manifold, Passenger Side

Part Number: 17140-38040$353.09 MSRP: $517.46You Save: $164.37 (32%)Ships in 1-3 Business DaysToyota Sequoia Exhaust Manifold, Driver Side

Part Number: 17105-50151$333.64 MSRP: $476.37You Save: $142.73 (30%)Ships in 1-2 Business DaysToyota Sequoia Exhaust Manifold, Passenger Side

Part Number: 17104-38011$416.99 MSRP: $611.10You Save: $194.11 (32%)Ships in 1-3 Business Days

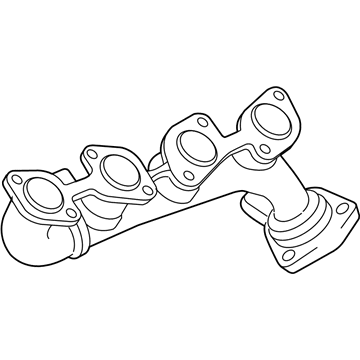

Toyota Sequoia Exhaust Manifold

Choose genuine Exhaust Manifold that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Exhaust Manifold for your Toyota Sequoia? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sequoia parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

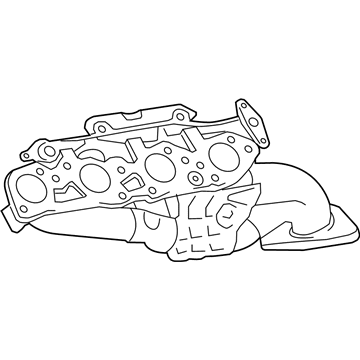

Toyota Sequoia Exhaust Manifold Parts and Q&A

- Q: How to remove the exhaust manifold on Toyota Sequoia?A:Start by clearing the Way of the No. 1 Engine Under Cover and conducting an engine coolant drain. The worker must remove the throttle body cover sub-assembly and sequentially remove the air cleaner hose assembly and air cleaner assembly. Both front fender apron seal rear LH and front fender apron seal LH need removal through clip removal of five and six pieces respectively. Once the manufacturing process for the exhaust manifold has begun first uninstall the Bank 1 No. 2 air hose and No. 3 air tube as well as the Bank 1 air switching valve assembly. The installation requires a complete repetition for both the front fender apron seal rear RH and front fender apron seal RH. Start by unscrewing the clip on the No. 5 water bypass hose then disconnect the heater outlet water hose together with the engine oil level dipstick guide. You must remove the water by-pass pipe assembly after disconnecting the 2 water hoses from the transmission oil cooler and removing 3 bolts. The service professional should disconnect the No. 2 air injection system hose and remove both the No. 2 air tube and air switching valve assembly for Bank 2. For the first step remove the front Exhaust Pipe assembly and then continue to the following step which requires removal of propeller shaft heat insulator and front propeller shaft assembly (4WD models only). The front No. 2 exhaust pipe assembly should be removed first before removing the No. 1 exhaust manifold heat insulator by detaching 4 bolts. Proceed with the removal of exhaust manifold sub-assembly RH by unfastening 8 nuts together with the gasket while also removing the No. 2 exhaust manifold heat insulator using 4 bolts before completing the procedure by taking off 8 nuts on the exhaust manifold sub-assembly LH along with its gasket.

- Q: How to install the exhaust manifold and associated components on Toyota Sequoia?A:The installation process for the exhaust manifold starts with placing a new gasket on the cylinder head whose "L" mark faces the manifold side while using the exhaust manifold sub-assembly LH temporarily for 8 new nut installations at a torque of 44 Nm (449 kgf-cm, 32 ft-lbf). Secure four bolts for the No. 2 exhaust manifold heat insulator then uniformly tighten them to 7.5 Nm (76 kgf-cm, 66 in-lbf). Place the steering intermediate shaft No. 2 sub-assembly in position next. Set the "R" mark on the new gasket facing the exhaust manifold direction before connecting the unit to the cylinder head temporarily. After installation adjust each of the 8 new nuts uniformly to their specified torque level. The No. 1 exhaust manifold heat insulator gets its installation through 4 bolts which should be tightened up to 7.5 Nm (76 kgf-cm, 66 in-lbf). After installing the front No. 2 Exhaust Pipe assembly proceed to set up the front propeller shaft assembly (for 4WD) and propeller shaft heat insulator (for 4WD). Proceed to install the front exhaust pipe assembly followed by the air switching valve assembly (for Bank 2), No. 2 air tube (for Bank 2), before connecting the No. 2 air injection system hose. The water by-pass pipe assembly should be installed by connecting two water hoses to the transmission oil cooler while securing the three bolts to 18 Nm (184 kgf-cm, 13 ft-lbf). Proceed to connect the No. 5 water by-pass hose to its clip before installing the heater outlet water hose and placing the engine oil level dipstick guide. To proceed install the air switching valve assembly followed by No. 3 air tube for Bank 1 then No. 2 air hose for Bank 1. Affix the air cleaner assembly together with the air cleaner hose assembly while adding engine coolant and verifying for any coolant leakage. After installing the throttle body cover sub-assembly you should put on the No. 1 engine under cover while conducting an exhaust gas leak inspection. Secure the four fender apron seals LH, rear LH, RH and rear RH by implementing proper clips.