×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Sequoia A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 A/C Clutches found

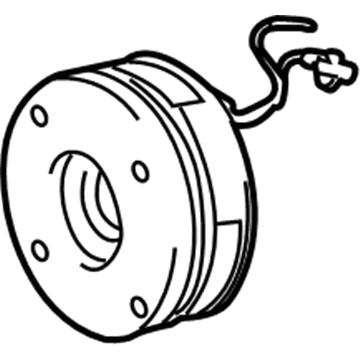

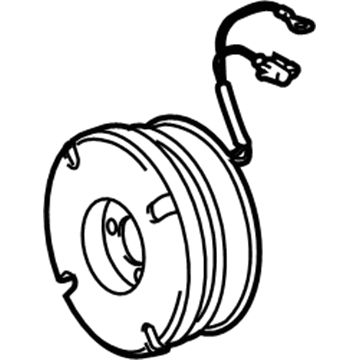

Toyota Sequoia Clutch & Pulley

Part Number: 88410-0C040$164.14 MSRP: $232.36You Save: $68.22 (30%)Ships in 1-3 Business Days

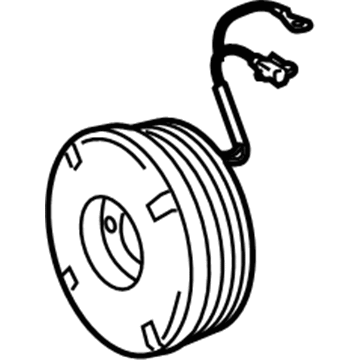

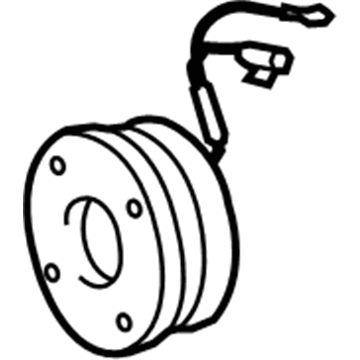

Toyota Sequoia Clutch Assembly, Magnet

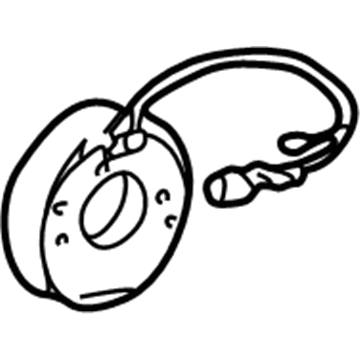

Part Number: 88410-6A090$143.46 MSRP: $203.08You Save: $59.62 (30%)Ships in 1-3 Business DaysToyota Sequoia Clutch Coil

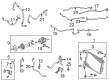

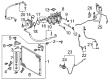

Part Number: 88411-02030$138.83 MSRP: $196.53You Save: $57.70 (30%)Ships in 1-3 Business DaysToyota Sequoia Clutch

Part Number: 88410-0C120$153.44 MSRP: $217.21You Save: $63.77 (30%)Ships in 1-3 Business DaysToyota Sequoia Clutch

Part Number: 88410-0C100$128.65 MSRP: $182.12You Save: $53.47 (30%)Ships in 1-3 Business DaysToyota Sequoia Clutch

Part Number: 88410-0C050$133.70 MSRP: $189.28You Save: $55.58 (30%)Ships in 1-3 Business DaysToyota Sequoia Clutch Assembly, Magnet

Part Number: 88410-0C140$486.11 MSRP: $712.40You Save: $226.29 (32%)Ships in 1-3 Business Days

Toyota Sequoia A/C Clutch

Choose genuine A/C Clutch that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Clutch for your Toyota Sequoia? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sequoia parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Toyota Sequoia A/C Clutch is an essential component in the automobiles air conditioning mechanism as widely used and noted across the different Sequoia models. This A/C Clutch plays the role of converting the energy of the engine to power the A/C compressor which is engaged as soon as the air conditioning system is turned on. This specific mechanism works by using a magnet to hold the drum within the belt pulley ensuring that the belt drive is locked and can operate to it is full potential when engaged or unloaded while the Toyota Sequoia A/C Clutch is disengaged so as not to put pressure on the engine unnecessarily. The benefits of this feature do not only cover improving the effectiveness of the A/C system but also increasing safety and efficacy of the Toyota Sequoia to a considerable degree. As the years go by, the Toyota Sequoia's application has gained a lot of respect when it comes to endurance, and this goes hand in hand with the A/C Clutch. Minor checks, proper lubrication or replacement of the A/C Clutch should not be neglected since they cause sticking or slipping of the clutch thus affecting the vehicle's A/C and its fuel economy. The Toyota Sequoia A/C Clutch simply ranks top in the automotive market today because of their design and durability together with suitability with both variations of the Sequoia cars whether being the first or second generation cars. The Toyota Sequoia A/C Clutch is one perfect example for this since it comes from a company that guarantees to provide only the premier quality automobiles and parts.

Toyota Sequoia A/C Clutch Parts and Q&A

- Q: How to service and repair the A/C Clutch on Toyota Sequoia?A:Service and repair operations for the compressor clutch start with disassembly work. Start by removing the pressure plate through the combination of Special Service Tool: 07112-76060 and a socket wrench to unbolt the shaft bolt while maintaining a torque rating of 18 N.m (184 kgf.cm, 12.3 ft-lbf). Place Special Service Tool: 07112-66040 on the pressure plate for operation with Special Service Tool: 07112-76060 and a socket wrench to separate the pressure plate from its position then extract all shims already present in the pressure plate. The tool Special Service Tool: 95994-10020 helps remove the snap ring while viewing the beveled side from above, then tap the rotor off the shaft using a plastic hammer with care to preserve the pulley. The method to remove the stator begins by removing the stator lead wire from the compressor housing followed by using Special Service Tool: 95994-10020 to dislodge the snap ring with its beveled side facing up and then extracting the stator. The steps for reassembly proceed in the opposite order of disassembly. Use the dial indicator set to the pressure plate to measure magnetic clutch clearance by connecting the magnetic clutch lead wire to the positive (+) terminal of the battery and verifying plate-rotor distance when applying the negative (-) terminal. The clearance zone measurement stands between 0.35 - 0.50 mm (0.014 - 0.024 in.) according to the standard. Standard shims with dimensions 0.1 mm (0.004 in.), 0.3 mm (0.012 in.) or 0.5 mm (0.020 in.) should be used to correct the clearance which falls outside the 0.35 - 0.50 mm (0.014 - 0.024 in.) range.

- Q: How to remove and replace the A/C Clutch on Toyota Sequoia?A:Before removing and replacing the compressor and magnetic clutch you must start the engine at idle speed with the air conditioner activated for ten minutes before shutting off the engine and disconnecting the negative battery cable. The refrigeration system requires discharging of refrigerant followed by disconnecting discharge and suction hoses by removing 2 nuts which must be capped instantaneously to block entry of moisture and dirt. To start, disconnect the power connector then unfasten all 3 bolts and the single nut while also detaching the cooler bracket. The compressor must be extracted after taking off the Drive Belt and cooler compressor. The installation process requires mounting the cooler compressor assembly with cooler bracket using 3 bolts and nut while torquing to 47 N.m (480 kgf.cm, 35 in.lbf) and 25 N.m (255 kgf.cm, 18 in.lbf) before connector connection. A proper connection of discharge and suction hoses requires installation with 2 nuts to 10 N.m (100 kgf.cm, 7 in.lbf) by applying compressor oil to 2 new O-rings before use. Install and check the drive belt, reconnect the cable to the negative battery terminal, evacuate air from the refrigeration system, and charge the system with refrigerant, using 750 plus or minus 50g (26.45 plus or minus 1.76 oz.) for single A/C or 1050 plus or minus 50g (37.03 plus or minus 1.76 oz.) for dual A/C. Inspect for refrigerant leakage using a gas leak detector, checking the tightening torque at the joints if any leakage is found, and perform initialization, noting that some systems require this when the cable from the negative battery terminal is disconnected.