×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

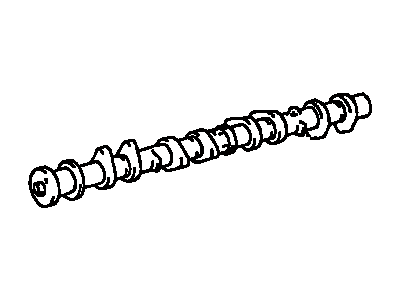

OEM Toyota MR2 Spyder Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Camshafts found

Toyota MR2 Spyder Camshaft

Part Number: 13502-22011$317.33 MSRP: $453.09You Save: $135.76 (30%)Ships in 1-3 Business DaysToyota MR2 Spyder Camshaft

Part Number: 13501-22042$337.98 MSRP: $482.56You Save: $144.58 (30%)Ships in 1-3 Business Days

Toyota MR2 Spyder Camshaft

Choose genuine Camshaft that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Camshaft for your Toyota MR2 Spyder? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota MR2 Spyder parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Toyota MR2 Spyder manufactured between 1999 and 2007 is well-known for its superb reliability and performance mostly due to the well-designed and manufactured camshaft. The camshaft in the Toyota MR Spyder car is significant to handle the operation of the intake and the exhaust valves of the car to allow proper air flow into the combustion chamber and releasing of toxic gases out of it. Made of iron or steel the camshaft is designed to convert rotary motion into reciprocal or oscillating motion a synchronize with crank shaft. This precision is important because it ensures the improvement of the efficiency of the Toyota MR2 Spyder in various of its models, Over Head Valve (OHV), Single Over Head Cam (SOHC), and Double Over Head Cam (DOHC). Such features as DOHC camshaft for example makes it possible to control the intake and exhaust valves separately and this helps the vehicle to have much more power and better efficiency. High RPM power is important in the MR2 Spyder but so is torque and idle which earns the Toyota MR2 Spyder camshaft a special place in the automotive market. Compatible with different car models of MR2 Spyder, the camshaft is one of the crucial components that promise an efficient and safe driving experience at the same time. Undeniably, the camshaft of the Toyota MR2 Spyder serves as one of those components that augment the functionality and defines this sleek limited-edition convertible sports car even in the Toyota entry in the automotive industry.

Toyota MR2 Spyder Camshaft Parts and Q&A

- Q: How to remove the camshaft on Toyota MR2 Spyder?A:The process to remove the camshaft begins by taking out the engine unit plus generator and ignition coils and spark plugs and injectors and exhaust manifold through disconnecting heated oxygen sensor connectors and then discarding heated oxygen sensors before uninstalling 4 upper heat insulator bolts and 4 exhaust manifold stays bolts and the exhaust manifold with its attached gasket and 5 bolts. Next, disconnect the engine wire by detaching the heated oxygen sensor (bank 1 sensor 1) wire from the 2 wire brackets, the camshaft timing oil control valve connector, the crankshaft position sensor connector, the knock sensor connector, the oil pressure switch connector and wire, the camshaft position sensor connector, the ECT sensor connector, the Throttle Position Sensor connector, the throttle control motor connector (SMT: 1), the accelerator position sensor connector (SMT: 2), the IAC valve connector, and the noise filter, then remove the 2 bolts and disconnect the 2 ground straps, followed by removing the 2 bolts and engine wire. Following this disconnect the PCV components by removing both PCV hoses and the PCV valve with its grommet. First disconnect the two water hoses from the Throttle Body and remove the two vacuum hoses from the Intake Manifold before you take out the four bolts and the two nuts and two wire brackets that allow for the removal of the intake manifold with throttle body assembly and its accompanying gasket. After the camshaft Timing Chain and timing sprocket and VVT sprocket removal process comes the removal of the camshaft timing oil control valve. To access camshaft components remove the 9 bearing caps together with the intake and exhaust camshafts after successive uniform bolt loosening of the 19 bearing cap bolts according to specified bolt sequences. The final step involves removing the cylinder head assembly after removing the water bypass pipe bolt from the cylinder head while applying a 10 mm bi-hexagon wrench for cyclic bolt loosening of the 10 cylinder head bolts in the correct order followed by removal of the 10 plate washers. Use a plastic prying tool to detach the cylinder head from the cylinder block while avoiding any surface damage to the contact areas. Remove the engine components by taking out the camshaft timing oil control valve filter as well as the camshaft position sensor and the ECT sensor.

- Q: How to install the camshaft on Toyota MR2 Spyder?A:Initially clean all parts before oil application to all sliding and rotating surfaces and install new gaskets while replacing oil seals. Silently place the cylinder head in place without damaging the gasket by keeping the lot No. facing upwards on the cylinder block surface. The first step involves applying engine oil to both cylinder head bolt threads and under their heads. Then install the 10 bolts with plate washers using a 10 mm bi-hexagon wrench while performing multiple torque steps until reaching a final torque of 49 Nm (36 ft lbs, 500 kgf-cm). Bolt replacement follows with a paint mark on the front part of the cylinder head bolt before re-torque to 90° using specified sequence to eliminate 90° mark visibility in relation to the front area. For the water bypass pipe bolt installation use 9 Nm (92 kgf-cm, 80 inch lbs.), while connecting the upper radiator hose and heater hose to the water hose union subsequently. The 2 camshafts should be placed on the cylinder head with the No. 1 cam lobes facing forwards according to the diagram while installing bearing caps in their designated positions. Finally, apply a thin layer of engine oil to both bolt threads and bearing cap bolt heads. Tighten all 19 bearing cap bolts evenly with a torque of 23 Nm (235 kgf-cm) for the No. 1 camshaft bearing cap while the remaining bolts should be tightened to 13 Nm (133 kgf-cm). Bring the camshaft timing oil control valve and filter together with the camshaft timing sprocket and VVT timing sprocket and Timing Chain and camshaft position sensor and oil filler cap and Intake Manifold with new gasket before uniformly tightening bolts and nuts to 30 Nm (306 kgf-cm, 22 ft. lbs.). Secure both vacuum hoses to the intake manifold while fitting the two water hoses to the Throttle Body before attaching the PCV valve with its grommet and hoses. Connect the engine wire to its 2 bolts, install the 2 ground straps before connecting all sensors and connectors that include the Throttle Position Sensor, IAC valve, ECT sensor, camshaft position sensor, oil pressure switch, knock sensor, crankshaft position sensor, camshaft timing oil control valve, and the heated oxygen sensor (bank 1 sensor 1) wire to its wire bracket. The exhaust manifold installation requires a new gasket while using 5 nuts tightened to 37 Nm (377 kgf-cm, 27 ft. lbs.) followed by installation of the 2 exhaust manifold stays using 4 bolts at equivalent torque. After installing the exhaust manifold with a new gasket and 5 nuts to 37 Nm (377 kgf-cm, 27 ft. lbs.), users can proceed to incorporate 2 heated oxygen sensors at 44 Nm (450 kgf-cm, 32 ft. lbs.) before connecting them. Install both the injectors along with spark plugs and ignition coils and generator and engine unit.