×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Highlander Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Differentials found

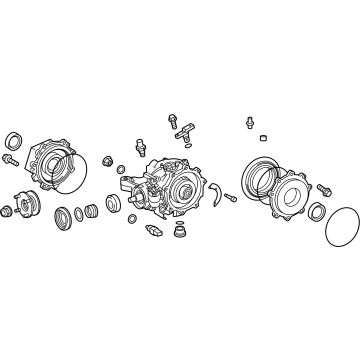

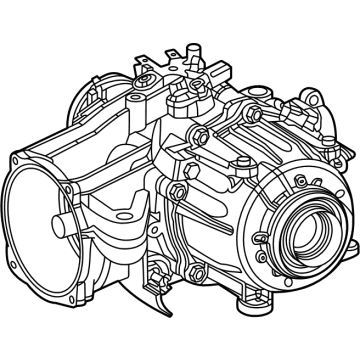

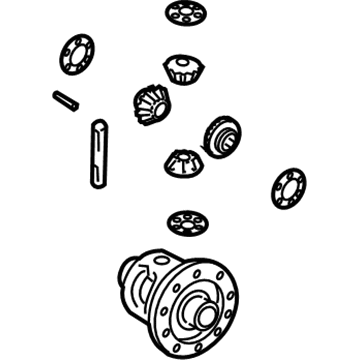

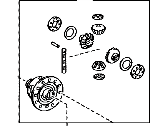

Toyota Highlander Case Sub-Assembly, Rear Differential

Part Number: 41301-48020$1866.87 MSRP: $2735.92You Save: $869.05 (32%)Ships in 1-3 Business DaysToyota Highlander Differential

Part Number: 41301-21060$518.34 MSRP: $759.64You Save: $241.30 (32%)Ships in 1-3 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-48123$1638.82 MSRP: $2401.70You Save: $762.88 (32%)Ships in 1-2 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-48112$2222.89 MSRP: $3257.66You Save: $1034.77 (32%)Ships in 1-2 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-48104$1093.56 MSRP: $1602.63You Save: $509.07 (32%)Ships in 1-3 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-48040$2042.21 MSRP: $2992.88You Save: $950.67 (32%)Ships in 1-3 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-48030$1736.08 MSRP: $2544.25You Save: $808.17 (32%)Ships in 1-3 Business DaysToyota Highlander Carrier Assembly, Rear

Part Number: 41110-21071$2026.19 MSRP: $2969.41You Save: $943.22 (32%)Ships in 1-3 Business Days

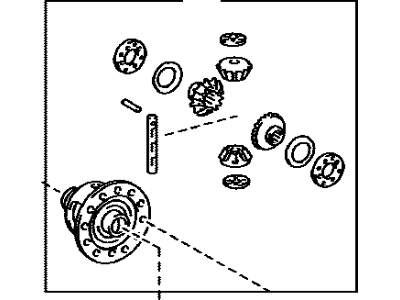

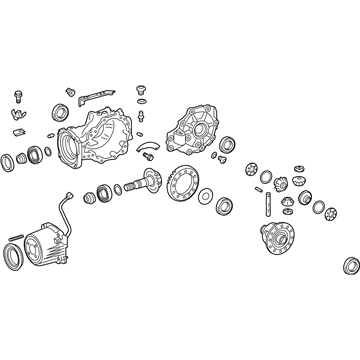

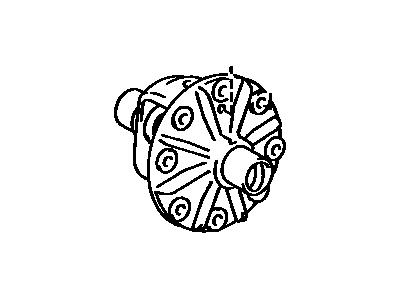

Toyota Highlander Differential Case

Part Number: 41311-14031$291.60 MSRP: $416.34You Save: $124.74 (30%)

Toyota Highlander Differential

Choose genuine Differential that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Differential for your Toyota Highlander? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Highlander parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Differential in Toyota Highlander vehicles is an important part of the drive train since it causes the drive wheels to rotate at different speed; this is desirable during cornering and on surfaces with different coefficient of friction. Highlander commonly employs open differentials, which allow the engine power to be divided between both wheels, and limited-slip differentials (LSD), which permits certain differences in torque distribution, the greatly benefiting the wheel with the better grip. What is true is that open differentials can have issues dealing with slippery surfaces, while LSDs offer better handling while at the same time can be difficult to start in slick surfaces. Highlander have adopted bevel and active differentials over the years making the performance and torque better. This mechanical device is highly vital in vehicle functioning, Daily maintenance is advisable since a low level of differential fluid is hazardous, for example.

Toyota Highlander Differential Parts and Q&A

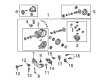

- Q: How to remove and replace the rear differential carrier assembly on Toyota Highlander?A:The process for removing the rear differential carrier assembly begins by extracting the rear wheel then removing the propeller with center bearing shaft assembly. The first step in differential carrier assembly replacement involves removing both the tail Exhaust Pipe assembly and the center exhaust pipe assembly. Begin by taking out the rear Speed Sensor on the left followed by the right side then remove the rear axle shaft nuts which also operate from the left side and right side. The following step requires removing both rear disc Brake Caliper assemblies followed by the removal of rear disks from both sides. First order is to remove the rear axle hub and bearing assemblies from both sides while following it with the removal of the No. 3 and No. 2 Parking Brake Cable assemblies. Starting from the rear, remove both strut rod assemblies before moving on to sub-assemblies of the rear axle carrier. The service professional should perform rear No. 2 suspension arm assembly removal for both sides alongside rear No. 1 suspension arm assembly RH removal. Attain the rear differential filler plug with a 10 mm hexagon wrench then proceed with draining the oil from the differential by removing the drain plug. Both rear Drive Shaft assemblies along with their snap rings need to be removed from the vehicle. Follow the procedure to take out the rear suspension member sub-assembly. Configuring a jack beneath the differential carrier assembly allows you to detach the No. 1 rear differential support from the rear suspension member sub-assembly using its 2 bolts and 2 lock nuts before removing the 3 bolts which separate the rear differential carrier assembly from the rear suspension member sub-assembly. Handle the rear differential carrier assembly with care and separate the No. 1 rear differential support by unbolted 2 hardware components and disassembled 2 locking nut mechanisms.

- Q: How to install the rear differential carrier assembly on Toyota Highlander?A:Before installing the rear differential carrier assembly install the No. 1 rear differential support with 2 bolts and 2 lock nuts that receive torque to 103 Nm (1050 kgf-cm, 76 ft-lbf). Install the No. 1 rear differential support by connecting it to the rear suspension member sub-assembly through 2 bolts and 2 lock nuts which should be torqued to 137 Nm (1400 kgf-cm, 101 ft-lbf). Thread 3 bolts onto the rear differential carrier assembly before torquing them to 95 Nm (970 kgf-cm, 70 ft-lbf) so it can be connected to the rear suspension member sub-assembly. The technicians must first install the rear No. 1 suspension arm assembly LH before proceeding to install both rear suspension member and rear Drive Shaft snap rings LH and RH. Put in place both rear drive shaft assemblies LH and RH before setting the rear No. 1 and No. 2 suspension arm assemblies RH and LH for temporary installation. The rear axle carrier sub-assemblies should be installed LH and RH then the rear strut rod assemblies for each side can be installed temporarily. The service procedure calls for rear axle hub and bearing assemblies LH and RH followed by rear discs on both sides then rear disc Brake Caliper assemblies LH and RH. Prior to installing the rear Speed Sensors LH and RH, install the rear axle shaft nuts LH and RH temporarily. After suspension stabilization complete a full torque sequence on both rear No. 1 and No. 2 suspension arm assemblies beside the rear strut rod assemblies. The installation of the No. 3 and No. 2 Parking Brake Cable assemblies leads to separating the rear disc brake caliper assemblies LH and RH before removing the rear discs from both sides. Both sides of rear axle hub bearing require inspection to measure looseness as well as runout. Both sides should receive rear discs and rear disc brake caliper assemblies before the installation of rear axle shaft nuts. First install the center and tail exhaust pipe assemblies, before tightening the propeller with center bearing shaft assembly temporarily and finally tightening it to completion. The rear differential drain plug requires a new gasket before installation with a 10 mm hexagon wrench and subsequent torque to 49 Nm (500 kgf-cm, 36 ft-lbf) before filling the rear differential carrier assembly with hypoid gear oil. The technician checks the differential oil before installing the filler plug with its new gasket for proper torque to 49 Nm (500 kgf-cm, 36 ft-lbf). After adjusting transfer oil levels the technicians should torque the rear wheel to 103 Nm (1050 kgf-cm, 76 ft-lbf). To complete the repair one must inspect rear wheel alignment and test the signal from the rear speed sensor and examine possible exhaust gas leaks.