×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Highlander ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

41 ABS Control Modules found

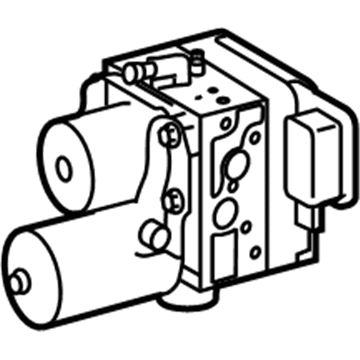

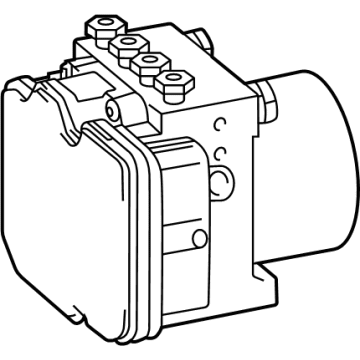

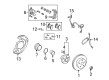

Toyota Highlander Actuator Assembly, Brake

Part Number: 44050-48191$1403.87 MSRP: $2057.39You Save: $653.52 (32%)Ships in 1-2 Business DaysToyota Highlander ABS Control Unit

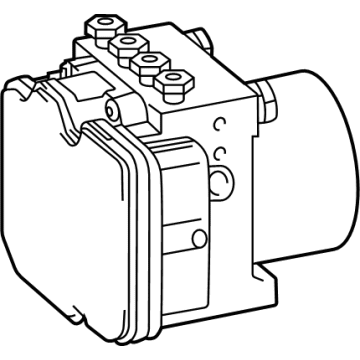

Part Number: 44050-0E580$965.65 MSRP: $1215.57You Save: $249.92 (21%)Ships in 1-3 Business DaysToyota Highlander Control Module

Part Number: 89540-48270$1841.86 MSRP: $2318.54You Save: $476.68 (21%)Ships in 1-3 Business DaysToyota Highlander Control Module

Part Number: 44050-0E540$836.71 MSRP: $1053.26You Save: $216.55 (21%)Ships in 1-2 Business DaysToyota Highlander Modulator Valve

Part Number: 44050-48530$1039.08 MSRP: $1308.00You Save: $268.92 (21%)Ships in 1-3 Business DaysToyota Highlander Computer

Part Number: 89540-48370$1345.22 MSRP: $1693.38You Save: $348.16 (21%)Ships in 1-3 Business DaysToyota Highlander Control Module

Part Number: 89540-48381$1573.21 MSRP: $1980.37You Save: $407.16 (21%)Ships in 1-3 Business DaysToyota Highlander Modulator Valve

Part Number: 44050-0E150$1004.46 MSRP: $1264.43You Save: $259.97 (21%)Ships in 1-3 Business DaysToyota Highlander Modulator Valve

Part Number: 44050-0E140$1056.90 MSRP: $1330.43You Save: $273.53 (21%)Ships in 1-3 Business DaysToyota Highlander Computer

Part Number: 89540-48380$1083.45 MSRP: $1363.86You Save: $280.41 (21%)Ships in 1-3 Business DaysToyota Highlander Control Module

Part Number: 89540-48230$1773.24 MSRP: $2232.17You Save: $458.93 (21%)Ships in 1-3 Business DaysToyota Highlander Control Module

Part Number: 89540-48240$329.92 MSRP: $404.60You Save: $74.68 (19%)Ships in 1-3 Business DaysToyota Highlander Modulator Valve

Part Number: 44050-0E190$965.65 MSRP: $1215.57You Save: $249.92 (21%)Toyota Highlander Modulator Valve

Part Number: 44050-48330$1234.64 MSRP: $1554.18You Save: $319.54 (21%)

| Page 1 of 3 |Next >

1-20 of 41 Results

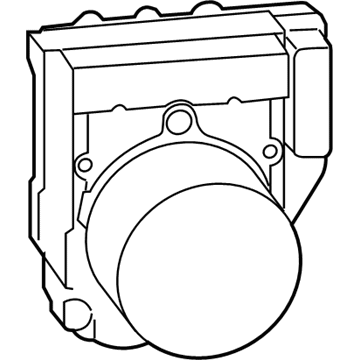

Toyota Highlander ABS Control Module

Choose genuine ABS Control Module that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM ABS Control Module for your Toyota Highlander? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Highlander parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Highlander ABS Control Module Parts and Q&A

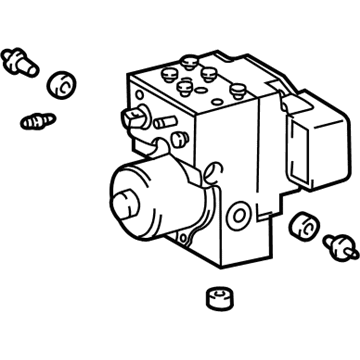

- Q: How to remove the ABS Control Module for Antilock Brakes on Toyota Highlander?A:A technician should begin Hydraulic Control Assembly for Antilock Brakes removal by disconnecting the negative battery cable while keeping track of procedures that could need system initialization after reconnecting. As the next step detach the V-bank cover sub-assembly. First detach the brake actuator with bracket by separating the relay box and unfastening the nut and bolt to remove the suction hose bracket from the brake actuator bracket assembly and seperating the No.1 cooler refrigerant suction tube from the two clamps while laying the tube next to the clamps. Open the lock lever to separate the brake actuator connector while preventing brake fluid entry into the taken connector. During the Brake Lines disconnect process union nut wrenches with sizes 10 mm and 12 mm will separate the six brake lines from the brake actuator with bracket where 1 connects to front wheel cylinder RH, 2 leads to front wheel cylinder LH, 3 routes to rear wheel cylinder RH, 4 serves rear wheel cylinder LH, 5 extends from 1st of master cylinder, while 6 extends from 2nd of master cylinder. Separate the brake actuator with bracket from the body by removing three bolts while being cautious about brake line and wire harness damage and after removing the piping clamp to extract the three bolts that detach the brake actuator from the brake actuator bracket assembly.

- Q: How to install the ABS Control Module on Toyota Highlander?A:The brake actuator installation requires 3 bolts that need to be tightened to 5.4 Nm (55 kgf-cm, 48 in-lbf) torque without removing hole plugs until all 6 Brake Lines are connected and while keeping contact away from the connector during the process. The bolts should be tightened according to their designated sequence. The brake actuator with bracket needs to be attached to the body through 3 bolts while applying 19 Nm torque (194 kgf-cm, 14 ft-lbf) but ensure brake lines and wire harness will not get damaged. During installation, doctors should restore each brake line to its marked position before tightening. Fully tighten each brake line using a union nut wrench (10 mm and 12 mm) with specific torque values: Flare Nut A (M10) without union nut wrench at 15 Nm (155 kgf-cm, 11 ft-lbf) and with union nut wrench at 14 Nm (143 kgf-cm, 10 ft-lbf); Flare Nut B (M12) without union nut wrench at 20 Nm (204 kgf-cm, 15 ft-lbf) and with union nut wrench at 18 Nm (184 kgf-cm, 13 ft-lbf), ensuring the use of a torque wrench with a fulcrum length of 250 mm (9.84 in.) and that the union nut wrench is parallel to the torque wrench. Once the brake actuator connector is attached correctly with contamination-free contact the system should proceed with attaching the No. 1 cooler refrigerant suction tube by securing it to both clamps before mounting the suction hose bracket onto the brake actuator bracket assembly with a 9.8 Nm (100 kgf-cm, 87 in-lbf) torque level. After this, fit the relay box. The procedure includes brake fluid addition to the reservoir and bleeding operations for master cylinder and both the brake line and actuator. Post-bleeding you need to check reservoir fluid levels and examine for any fluid leaks before installing the V-bank cover sub-assembly on 2GR-FE models along with installing No. 1 engine cover sub-assembly on 1AR-FE cars while reconnecting the negative battery cable and recording that some systems need initialization steps. The inspection of the brake actuator through Techstream must be combined with yaw rate and acceleration sensor zero point calibration followed by a diagnostic test and DTC check.