×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Celica A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 A/C Clutches found

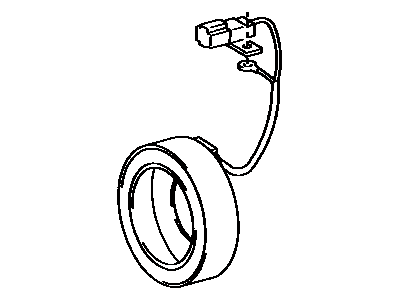

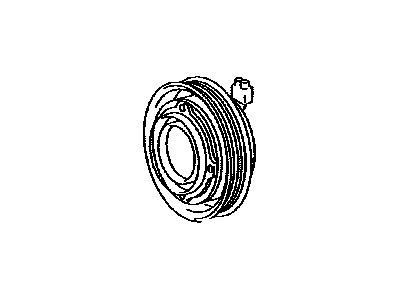

Toyota Celica Clutch Coil

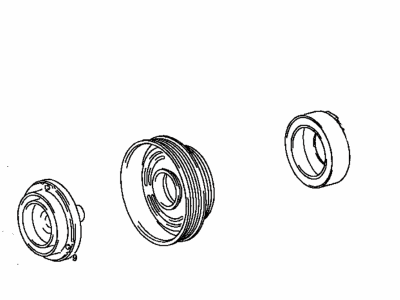

Part Number: 88410-2B100$146.17 MSRP: $206.92You Save: $60.75 (30%)Ships in 1-3 Business DaysToyota Celica Clutch

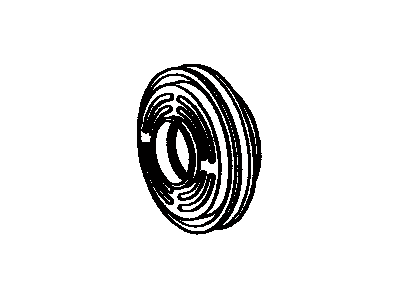

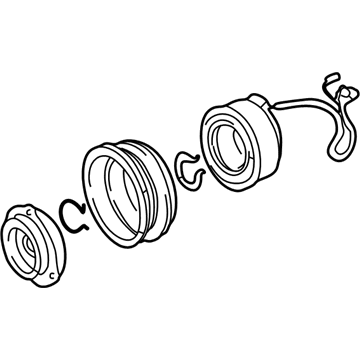

Part Number: 88410-33070$608.79 MSRP: $892.20You Save: $283.41 (32%)Ships in 1-3 Business DaysToyota Celica Pulley

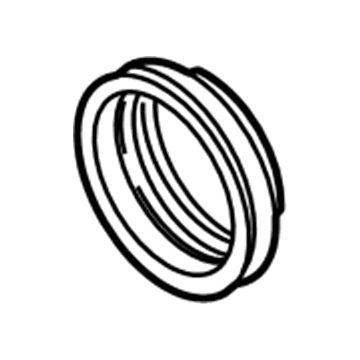

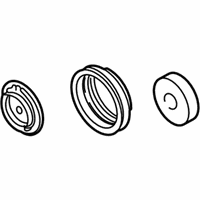

Part Number: 88412-32120$275.60 MSRP: $393.50You Save: $117.90 (30%)Ships in 1-3 Business DaysToyota Celica Compressor Pulley

Part Number: 88412-33050$335.66 MSRP: $479.24You Save: $143.58 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 27 Results

Toyota Celica A/C Clutch

Choose genuine A/C Clutch that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Clutch for your Toyota Celica? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Celica parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Celica A/C Clutch is among the well-known auto parts providing services in Toyota Celica cars due to its efficiency in offering air conditioning system. Featuring this A/C clutch is designed to convert energies from the engine to power the A/C compressor and it connects when the A/C is turned on. It has been designed to offer less load on the engine thus improving on the efficiency and safety of the engine at the time of operation. The A/C Clutch component has been well integrated applying it in different generations of Toyota Celica; right from the design of 1970s up to the complex design of late 1990s. This versatility however goes to show that the Toyota Celica has a primary focus that is performance/reliability. Most noteworthy, the A/C Clutch in many models contains electronic functions that offer a better response and less of a problem in either sticking or slipping. Adequate servicing and replacement of the A/C Clutch is called for to ensure that the system and fuel efficiency are preserved as well as to avoid possible harm to the A/C system. As for the Toyota Celica A/C Clutch, it is a distinctive device in the automotive market because of its solid structure and the effectiveness of its working due to the original design. The Toyota Celica is still one of the most remembered models due to its history and its evolution; the A/C Clutch is an essential part to make drivers to drive certified, in a comfort and in a safety way depending on the generation.

Toyota Celica A/C Clutch Parts and Q&A

- Q: How to service and repair the A/C Clutch on Toyota Celica?A:The first step to maintain the compressor clutch requires allowing the engine to operate at idle speed with the A/C on for ten minutes followed by stopping the engine and removing the negative cable from the battery terminal. Remove the Drive Belt from the system after discharging the refrigeration system refrigerant. The service requires removal of the cruise control actuator during the 1ZZ-FE engine work and the air pump assembly removal during the 2ZZ-GE engine tasks. Removing the 2 bolts from discharge and suction hoses enables capping the open fittings to stop moisture or dirt from entering the system. Uninstalling the compressor requires disconnecting its connector and wire harness clamp together with removing 3 bolts. Follow these instructions to install the compressor: first fasten it with the 3 bolts at 25 N.m (250 kgf.cm, 18 ft.lbf) torque setting then restore the connector linkage. Set up the discharge and suction hoses through the compressor oil lubricating process of 2 new O-rings which should be installed to their hose positions before tightening 2 corresponding bolts to 10 N.m (100 kgf.cm, 7 ft.lbf torque). Cruise control actuators should be installed with the 1ZZ-FE engine but air pump assemblies need installation with the 2ZZ-GE engine. Reinstall and check the drive belt after which you should connect the negative (-) terminal cable to the battery. Evacuate the refrigeration system followed by the installation of specified refrigerant amount at 430 plus or minus 30 g (15.17 plus or minus 1.06 oz.). An inspection of refrigerator leakage with a gas leak detector should be performed and a torque check for loose fitting joints should be conducted when any leakages are detected as part of the A/C inspection process.