×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Camry A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

46 A/C Clutches found

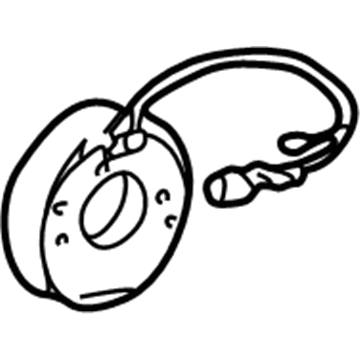

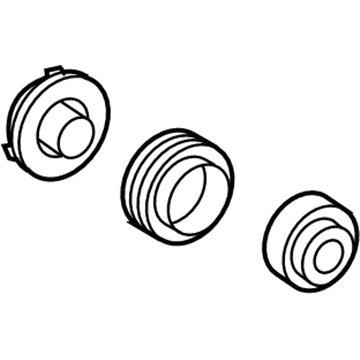

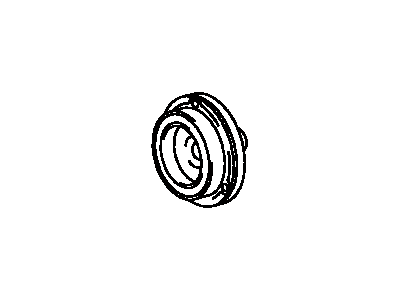

Toyota Camry Hub Sub-Assembly, Magnet Clutch

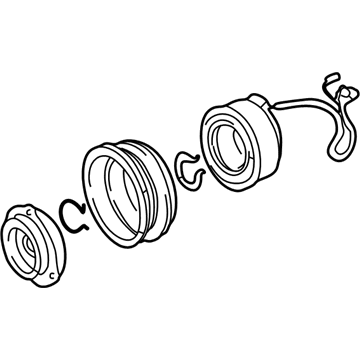

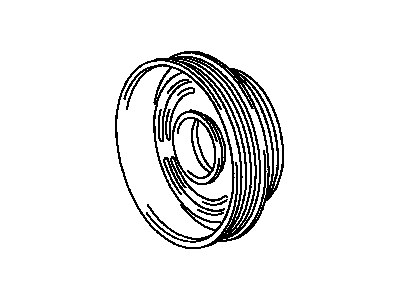

Part Number: 88403-32010$133.43 MSRP: $188.90You Save: $55.47 (30%)Ships in 1-3 Business DaysToyota Camry Clutch & Pulley

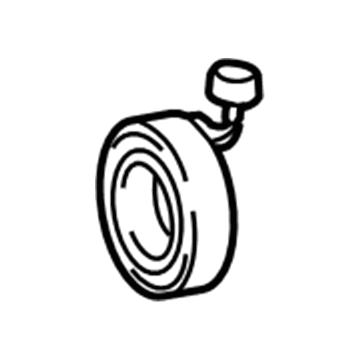

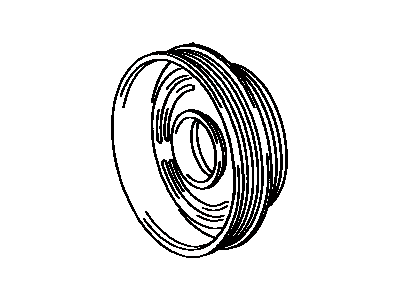

Part Number: 88410-33110$661.13 MSRP: $968.89You Save: $307.76 (32%)Ships in 1-3 Business DaysToyota Camry Pulley

Part Number: 88412-42010$327.99 MSRP: $468.29You Save: $140.30 (30%)Ships in 1-3 Business DaysToyota Camry Pulley

Part Number: 88412-07020$282.51 MSRP: $403.36You Save: $120.85 (30%)Ships in 1-3 Business DaysToyota Camry Pulley

Part Number: 88412-33040$342.26 MSRP: $501.58You Save: $159.32 (32%)Ships in 1-3 Business DaysToyota Camry Compressor Pulley

Part Number: 88412-33050$335.66 MSRP: $479.24You Save: $143.58 (30%)Ships in 1-3 Business DaysToyota Camry Clutch

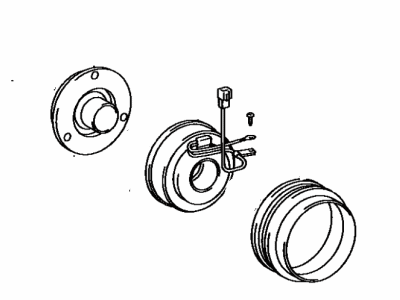

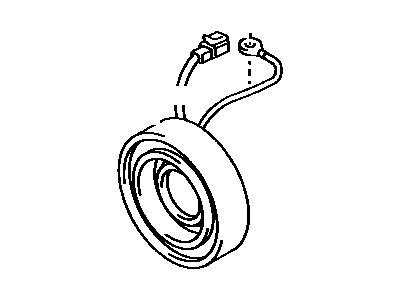

Part Number: 88410-33020$123.38 MSRP: $175.00You Save: $51.62 (30%)Ships in 1-3 Business DaysToyota Camry Clutch Coil

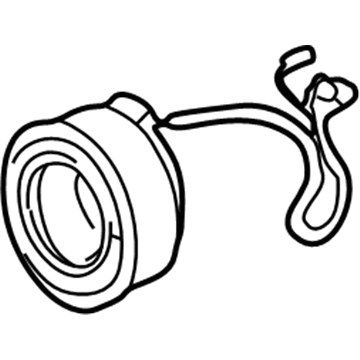

Part Number: 88411-22290$135.13 MSRP: $191.29You Save: $56.16 (30%)Ships in 1-3 Business DaysToyota Camry Clutch Coil

Part Number: 88411-33030$107.21 MSRP: $150.49You Save: $43.28 (29%)Ships in 1-3 Business DaysToyota Camry Clutch Coil

Part Number: 88411-02030$138.83 MSRP: $196.53You Save: $57.70 (30%)Ships in 1-3 Business DaysToyota Camry Clutch

Part Number: 88410-32060$123.62 MSRP: $175.00You Save: $51.38 (30%)Ships in 1-3 Business DaysToyota Camry Clutch Coil

Part Number: 88411-33050$143.06 MSRP: $202.51You Save: $59.45 (30%)Ships in 1-3 Business DaysToyota Camry Clutch Coil

Part Number: 88411-44010$115.51 MSRP: $162.14You Save: $46.63 (29%)Ships in 1-3 Business DaysToyota Camry Clutch & Pulley

Part Number: 88410-07020$128.65 MSRP: $182.12You Save: $53.47 (30%)Ships in 1-3 Business DaysToyota Camry Clutch Assembly, Magnet

Part Number: 88410-33010$133.36 MSRP: $175.00You Save: $41.64 (24%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 46 Results

Toyota Camry A/C Clutch

Choose genuine A/C Clutch that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Clutch for your Toyota Camry? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Camry parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

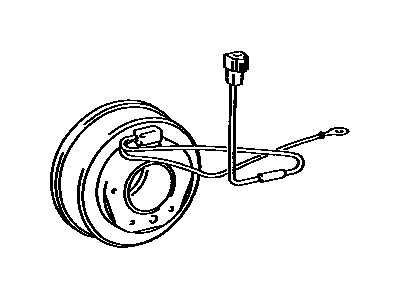

The Toyota Camry A/C Clutch is a product essential to the air conditioning system trusted for its dependability and efficiency across Camry generations. This A/C clutch comes on when the air conditioning system is turned on and enables the transfer of refrigerant from the compressor to the evaporator for cooling purpose. Toyota has ensured that A/C Clutch is integrated in a pulley system meant to acquire an electromagnet coil to facilitate the energy transfer from the engine. Besides, it optimizes the functioning of the A/C system and is also a factor in the vehicle's safety and comfort level. This entry, the Toyota Camry A/C Clutch, has received a lot of commendations for its long-wearing quality which makes it popular with automobile users. Some of these parts can be used in multiple generations of Camry, from as early as 1982 up to the most recent models; thus, owners will always be sure of where to get the Camry parts they require. A worn or defective A/C Clutch also results in a decreased performance and therefore a conclusive call to get it replaced on time. Advanced features of the Toyota Camry A/C Clutch, for instance the materials and workmanship applied in it, the accurate engagement system applied in the manufacture of its product make it unique in the market place, thus underlining Toyota's strategic plan of producing quality and value added vehicles. In totality, the Toyota Camry A/C Clutch is a clear testimony to the automobile giants' commitment to optimizing vehicle performance and subsiding the convenience of the driver.

Toyota Camry A/C Clutch Parts and Q&A

- Q: How to service and repair the A/C Clutch on Toyota Camry?A:Service and repair of the compressor clutch follow these steps: let the engine reach idle speed with A/C turned on for ten minutes before engine shutdown and battery terminal cable detaching. Eliminate refrigerant from the refrigeration system before proceeding to remove the Drive Belt. When working on 1MZ-FE engines begin by removing the suction hose through bolt removal from its clamp then disconnect the wire harness clamp and unscrewing all nut and bolt components. Immediately place caps over open system fittings in order to block out moisture and dirt intrusion. Proceed with disconnecting the discharge hose after you remove its bolt and apply caps to the exposed fittings. You should start by disconnecting the generator connector followed by taking out the nut and wire before disconnecting the wire harness from its clip and taking out the pivot bolt and plate washer along with the adjusting lock bolt. Connect 5S-FE engine models by detaching suction and discharge hoses through the removal of two bolts followed by fitting caps to the ends. Detach the compressor by disconnecting the connector while removing its three bolts. Engine 1MZ-FE requires users to disconnect the connector before removing two bolts and a nut with the drive belt adjusting bar bracket followed by taking out the compressor through three bolt removal. The installation of the compressor for 5S-FE engine models necessitates bolt installation at three locations with the torque set to 25 N.m (250 kgf.cm, 18 ft.lbf) and connector attachment afterwards. To install the compressor on 1MZ-FE engines position the three bolts with equal torque while next installing the drive belt adjusting bar bracket through two bolts and a nut which needs tightening to 25 N.m (250 kgf.cm, 18 ft.lbf) for Bolt (A), 18 N.m (185 kgf.cm, 13 ft.lbf) for bolt (B) and 25 N.m (250 kgf.cm, 18 ft.lbf) for the nut before connecting the connector. Attach 2 bolts on the discharge and suction hoses of 5S-FE engine models while torquing them to 10 N.m (100 kgf.cm, 7 ft.lbf). Before hose installation, apply compressor oil to two new O-rings. On 1MZ-FE engine models position the generator on its bracket using the pivot bolt and adjusting lock bolt but maintain them loose before connecting both the generator connector and generator wire with its nut. The compressed air hose requires installation using a bolt securing it with 10 N.m (100 kgf.cm, 7 ft.lbf) torque strength during which compressing oil should be used to lubricate the new O-ring before assembly. The procedure begins with plumbing and tightening the suction hose join by screwing the bolt and nut to 32 N.m (330 kgf.cm, 24 ft.lbf) values at the piping intersection then continuing with suction hose clamping bolt installation and wire harness clamp attachment. Install the drive belt next then restore the negative terminal cable connection before evacuating air from the system and charging it with 800 plus or minus 50 g (28.22 plus or minus 1.76 oz.) of refrigerant. A gas detector should be used to check for leaks while technicians should refasten loose joints with their specified torque settings. When leaks are identified the system should undergo an A/C operation check together with additional testing for leakage.