×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion xA A/C Condenser

Air Conditioning Condenser- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 A/C Condensers found

Scion xA Condenser

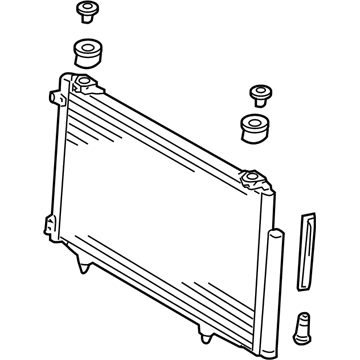

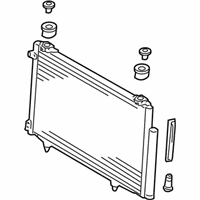

Part Number: 88460-AZ039$125.81 MSRP: $177.81You Save: $52.00 (30%)Ships in 1-3 Business DaysScion xA Condenser

Part Number: 88450-52231$324.79 MSRP: $463.73You Save: $138.94 (30%)Ships in 1-3 Business DaysScion xA Condenser

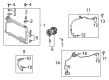

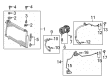

Part Number: 88450-52230$325.65 MSRP: $464.96You Save: $139.31 (30%)Ships in 1-3 Business DaysScion xA Discharge Hose

Part Number: 88450-52131$247.15 MSRP: $352.88You Save: $105.73 (30%)Ships in 1-2 Business Days

Scion xA A/C Condenser

Choose genuine A/C Condenser that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Condenser for your Scion xA? Our website is your one-stop destination. We stock an extensive selection of genuine Scion xA parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Scion xA A/C Condenser as one of the best-selling automobile parts needs no introduction as it incorporates quality in performance for automobiles in the market. As one of the heat exchangers, the A/C Condenser plays a major role of cooling the gaseous refrigerant in order to turn it into liquid as it proceeds to the accumulator. The described process contributes to the proper climate control inside of the Scion xA's cabin, and therefore provides drivers and passengers with comfortable air conditioning. Similar to the radiator, the A/C Condenser is placed at the front part of the vehicle and also contains a series of tubes used for transfer of heat. This makes it quite important in regard to allied Scion xA models as it improves the general performance as well as safety of the automobile. The Scion xA is powered by a very reliable 1.5 L DOHC I4 engine; the A/C Condenser is efficient in regulating temperatures, fortified by the car's fuel efficiency of 27 mp/g in the city and 34 mp/g on the highway. Thirdly, A/C Condenser also has its function in the movements of the car and efficient acceleration and proper acceleration leading to a good ride. However, it is notable that Scion xA A/C Condenser has a rather robust construction and outlook, so it will not let you down for a long time. All in all, the Scion xA A/C Condenser is definitely one of the very important parts of the car since it provides not only comfort to the passengers but also proper working condition of the vehicle.

Scion xA A/C Condenser Parts and Q&A

- Q: How to overhaul the A/C Condenser with receiver condenser assembly on Scion xA?A:The first step to overhaul the HVAC condenser with receiver condenser assembly demands the use of Special Service Tool 07110-58060 (07117-58080, 07117-58090, 07117-78050, 07117-88060, 07117-88070, 07117-88080) to evacuate refrigerant from the refrigeration system. Ubolt the radiator grille along with low pitched horn assembly and high pitched horn assembly by removing 3 bolts simultaneously while removing the hood lock support sub assembly by unclipping then removing its 2 bolts. Seal the openings of the cooler refrigerant discharge hose No.1 after removing its bolt and O-ring by applying vinyl tape to stop moisture and foreign matter from entering. Dismount liquid tube sub assembly A which requires removal of its O-ring and secure both ends with sealed vinyl tape. You must first remove two bolts from the w/receiver condenser assembly before moving on to the condenser bracket collar No.1 by taking out its two bolts. Insert a 14 mm socket hexagon wrench to remove the cooler dryer before taking off its cap and O-ring and finally remove it with pliers. Use pliers to install the new cooler dryer and then place a new O-ring onto the cap surface before adding compressor oil from the ND-OIL 8 or equivalent product line to both surfaces. Secure the cap with pliers under 2.9 Nm (29 kgf.cm, 25 in.lbf) torque. Begin with placing the two condenser bracket collar No.1 bolts at 3.9 Nm (40 kgf.cm, 35 in.lbf). Then proceed with w/receiver condenser assembly bolt installation at 9.8 Nm (100 kgf.cm, 87 in.lbf). Subassembly A of the liquid tube requires compressor oil to be applied on both a new O-ring and hose joint before being fastened with a bolt at 5.4 Nm (55 kgf.cm, 48 in.lbf). The cooler refrigerant discharge hose No.1 receives its compressor oil on a new O-ring before being bolted at 5.4 Nm (55 kgf.cm, 48 in.lbf). First install the hood lock support sub assembly through its 2 bolts reaching torque of 5.0 Nm (51 kgf.cm, 44 in.lbf) before attaching the clip followed by assembly of the hood lock with 3 bolts then the high and low pitched horn assemblies. Allow the hood sub assembly to reach its tolerance through adjustment while using Special Service Tool: 07110-58060 (07117-58060, 07117-58070, 07117-58080, 07117-58090, 07117-78050, 07117-88060, 07117-88070, 07117-88080) to add refrigerant to 460 plus or minus 30 g (16.2 plus or minus 1.1 oz.), then warm the engine before checking for leaks.

- Q: How to properly remove and install an A/C Condenser on Scion xA?A:A correct removal of the condenser HVAC starts with battery terminal cable uncoupling followed by a minimum 90-second wait period for Air Bag safety. Start by evacuating the refrigeration system of refrigerant before you remove three bolts on the radiator grille, low pitched horn assembly, high pitched horn assembly and hood lock assembly. You must take off the hood lock support sub-assembly by detaching its clip and unfastening the two bolts. Thoroughly isolate the No. 1 cooler refrigerant discharge hose by unthreading its bolt then unhook its O-ring followed by wrapping the hose ends in vinyl tape to stop moisture and foreign materials from getting inside. The liquid tube sub-assembly requires removal of its bolt and O-ring before sealing both ends with vinyl tape. Disassemble the condenser with receiver assembly by uninstalling its two bolts. To install the condenser with receiver assembly use 2 bolts that require 9.8 N.m torque (100 kgf.cm, 7 ft.lbf). The liquid tube sub-assembly installation begins by removing vinyl tape before applying compressor oil (ND-OIL 8 or equivalent) to a new O-ring and its installation followed by securing the liquid tube using a bolt that reaches 5.4 N.m (55 kgf.cm, 48 in.lbf) torque. The No. 1 cooler refrigerant discharge hose installation includes removing the vinyl tape followed by compressive oil application to a new O-ring while installing the O-ring before securing the hose with the bolt at 5.4 N.m (55 kgf.cm, 48 in.lbf) torque specification. First install the hood lock support sub-assembly by bolting it two times to 5.0 N.m (51 kgf.cm, 44 in.lbf) torque and clip in before adding the hood lock assembly using three bolts. Reinstall the high pitched horn assembly together with the low pitched horn assembly and radiator grille. First normalize the hood sub-assembly before repairing the negative battery cable then initialize all systems that need it after reconnecting the cable to the terminal. The technician conducts refrigerant charging while heating up the engine while inspecting for refrigerant escapes.