×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2009 Toyota FJ Cruiser Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Axle Shafts found

2009 Toyota FJ Cruiser Axle Assembly

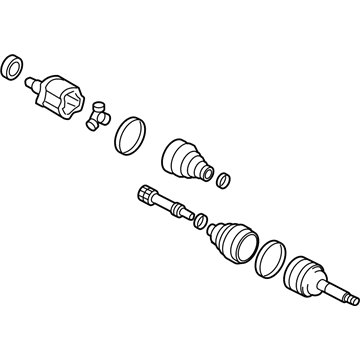

Part Number: 43430-60061$419.71 MSRP: $615.09You Save: $195.38 (32%)Ships in 1 Business DayProduct Specifications- Other Name: CV Axle Assembly, Front Left, Front Right; CV Axle Assembly; GSP Cv Axle; Axle Shaft

- Replaced by: 43430-60062

- Item Weight: 24.50 Pounds

- Item Dimensions: 31.3 x 5.2 x 5.4 inches

- Condition: New

- SKU: 43430-60061

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

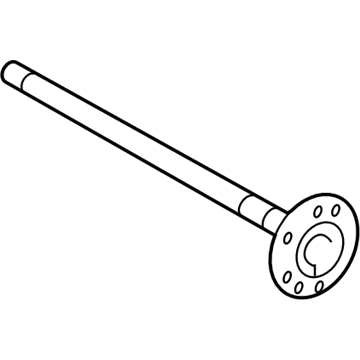

2009 Toyota FJ Cruiser Axle Shaft, Rear

Part Number: 42311-60240$477.48 MSRP: $699.76You Save: $222.28 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts; Shaft, Rear Axle, Passenger Side; Shaft, Rear Axle, Driver Side

- Position: Rear

- Item Weight: 16.10 Pounds

- Item Dimensions: 29.3 x 9.0 x 7.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42311-60240

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota FJ Cruiser Axle Shaft

Looking for affordable OEM 2009 Toyota FJ Cruiser Axle Shaft? Explore our comprehensive catalogue of genuine 2009 Toyota FJ Cruiser Axle Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2009 Toyota FJ Cruiser Axle Shaft Parts Q&A

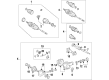

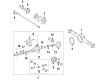

- Q: How to install the rear axle shaft and related components on 2009 Toyota FJ Cruiser?A: The installation process for the rear axle shaft begins with new oil seal installation using Special Service Tool: 09950-60020 09951-00770 and a hammer followed by lip application of MP grease. After greasing a new O-ring with MP grease, install it followed by fitting the rear axle shaft with the parking brake plate and torquing 4 nuts to 120 Nm (1,224 kgf-cm, 89 ft-lbf). The bearing examination for the rear axle shaft must be conducted before installation of the rear speed sensor. Two bolts secure the parking brake plate by torquing it to 8.0 Nm (82 kgf-cm, 71 in-lbf). High-temperature grease should be applied before mounting the parking brake shoe and its two accompanying parts: shoe strut and return tension spring. The parking brake system needs inspection before placing the rear disc and performing parking brake shoe clearance adjustment. Install the rear disc brake caliper assembly through its 2 bolts together with 2 washers while torquing them to 105 Nm (1,071 kgf-cm, 78 ft-lbf). After that, attach the flexible hose with a new clip. Connect the brake tube to flexible hose through the use of Special Service Tool: 09023-00101 according to specified torque values: 15 Nm (155 kgf-cm, 11 ft-lbf) when not using the tool while the recommended torque rate with the tool amounts to 14 Nm (143 kgf-cm, 10 ft-lbf). Both torque specifications require a torque wrench with a 300 mm (11.81 in.) fulcrum and run parallel to the tool. Connect the cable to the negative terminal of the battery using 3.9 Nm (40 kgf-cm) torque while installing the rear wheel to 112 Nm (1,137 kgf-cm). After inspecting the differential oil and checking for leakage the system requires brake fluid filling before braking line bleeding and checking reservoir fluid level and additional examination for brake fluid leakages. The inspection of the parking brake lever travel must be followed by necessary adjustments and the VSC sensor signal must be checked last.