×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2007 Toyota RAV4 Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rack And Pinions found

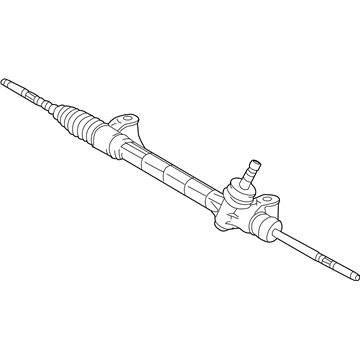

2007 Toyota RAV4 Steering Gear

Part Number: 45510-42240$653.07 MSRP: $957.08You Save: $304.01 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly

- Replaces: 45510-0R020, 45510-42040, 45510-42090, 45510-42110

- Condition: New

- SKU: 45510-42240

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota RAV4 Steering Gear

Part Number: 45510-42230$626.05 MSRP: $917.49You Save: $291.44 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly

- Replaces: 45510-42030, 45510-42100, 45510-0R100, 45510-0R010, 45510-0R070, 45510-42080

- Condition: New

- SKU: 45510-42230

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota RAV4 Rack And Pinion

Looking for affordable OEM 2007 Toyota RAV4 Rack And Pinion? Explore our comprehensive catalogue of genuine 2007 Toyota RAV4 Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2007 Toyota RAV4 Rack And Pinion Parts Q&A

- Q: How to service and repair the Rack And Pinion on 2007 Toyota RAV4?A: The repair process of rack and pinion starts by aligning front wheels to the straight ahead position while disconnecting the battery cable from the negative terminal and waiting 90 seconds to avoid Air Bag deployment. First disconnect the No. 2 tie rod end sub-assembly with Special Service Tool: 09628-62011 by unbolting the tie rod end from the steering knuckle while protecting the dust cover. Simon will duplicate the same repairs for the No. 1 tie rod end sub-assembly. Begin by first removing the column hole cover silencer sheet by taking out the floor carpet and clips then disconnect the steering sliding yoke sub-assembly by securing the steering wheel with a seat belt before marking the sliding yoke and removing the bolt for its disconnection. The first step includes removing sub-assembly clips A and B to separate the No. 1 steering column hole cover followed by separating engine assembly with transaxle. Tear the column hole cover off from the rack and pinion before marking the intermediate shaft and then removing it from the rack and pinion. Disassemble the rack and pinion assembly by removing all the bolts and nuts but protect the nut from rotating movement. The No. 1 tie rod end sub-assembly requires special service tool 09612-00012 which needs protective tape before a vise installation allows the sub-assembly's removal together with the rack end marking. Repeat the same steps during the No. 1 tie rod end sub-assembly installation. Inspect the No. 2 tie rod end sub-assembly ball joint by placing it in a vise while installing the castle nut and checking its turning torque with a torque wrench to confirm the measurement between 0.98 to 3.92 Nm. Run the same tie rod end sub-assembly evaluation sequence also on the No. 1 component. The inspection of total preload with Special Service Tool: 09616-00011 must stay within the range of 0.7 to 1.3 Nm or the rack and pinion should get replaced. Knock down the lock nut along with the No. 2 tie rod end sub-assembly to the rack end but stop when in alignment before tightening the lock nut to full specification for toe-in adjustment. Conduct the same sequence with the No. 1 tie rod end sub-assembly. Mount the rack and pinion onto the front suspension crossmember using bolts and nuts while tightening them to 138 Nm while maintaining the nut stationary. Place matchmarks correctly before installing the intermediate shaft onto the rack and pinion and apply 35 Nm torque to it. The engine assembly and transaxle installation follows the sub-assembly of the new-clamped hole cover to the steering column. Secure No. 1 hole cover together with clip A on the sub-assembly by checking the lip remains unharmed. The interpolation process requires a 35 Nm torque for connecting the sliding yoke onto the intermediate shaft before installing the column hole cover silencer sheet with clips and the floor carpet. The sub-assembly of the No. 2 tie rod end needs to be attached to the steering knuckle at a torque setting of 49 Nm but can require additional tightening as needed followed by new cotter pin installation. The same installation technique should be used for the No.1 tie rod end sub-assembly until it reaches a torque of 103 Nm before installing the front wheels. Reposition the cable to the negative battery terminal before aligning the front wheels straight ahead while conducting an inspection and adjustment of the front wheel alignment.