×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Sequoia Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rack And Pinions found

2006 Toyota Sequoia Rack, Front

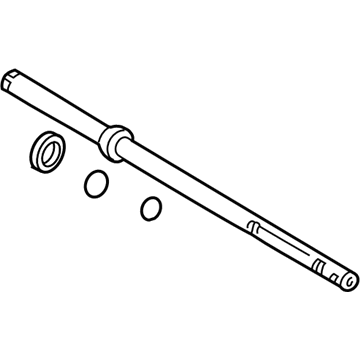

Part Number: 44204-0C011$580.43 MSRP: $850.63You Save: $270.20 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rack Sub-Assembly, Power; Rack And Pinion Rack Gear, Front; Steering Gearbox; Steering Rack; Rack Sub-Assembly, Power Steering

- Position: Front

- Part Name Code: 44204

- Item Weight: 5.70 Pounds

- Item Dimensions: 32.1 x 3.3 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44204-0C011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

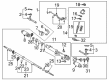

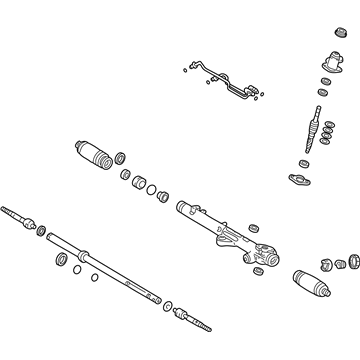

2006 Toyota Sequoia Steering Gear

Part Number: 44250-0C041$722.76 MSRP: $1059.21You Save: $336.45 (32%)Product Specifications- Other Name: Gear Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Rack & Pinion; Gear Assembly; Gear Assembly, Power Steering(For Rack & Pinion)

- Manufacturer Note: W(REAR STABILIZER)

- Replaces: 44250-0C050, 44250-0C020

- Part Name Code: 44250

- Item Weight: 1.40 Pounds

- Item Dimensions: 3.4 x 3.2 x 3.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44250-0C041

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Sequoia Rack And Pinion

Looking for affordable OEM 2006 Toyota Sequoia Rack And Pinion? Explore our comprehensive catalogue of genuine 2006 Toyota Sequoia Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Sequoia Rack And Pinion Parts Q&A

- Q: How to service and repair the power Rack And Pinion on 2006 Toyota Sequoia?A: The first step for repairing or servicing the power steering rack and pinion requires disconnecting the negative battery terminal then allowing 90 seconds of wait time to avoid Air Bag activation. Begin the power steering rack and pinion repair by directing the front wheels forward before you remove both the steering wheel pad along with its assembly. The removal of the bolt enables you to disconnect the No. 2 intermediate shaft assembly as well as both tie rod end sub-assemblies and the clamp plate. Disconnect the pressure feed tube assembly with Special Service Tool: 09023-12701 and the return tube assembly using the identical tool. Start the PS rack and pinion assembly removal process by unfastening three fixtures from the bracket and proceeding to detach two set bolts along with their nut and washer until the PS assembly becomes disembedded. Separate the rack and pinion assembly through a vise operation, being cautious not to excessively tighten it. After removed grommet and bracket elements, proceed with rack and pinion disassembly. Follow the directions of Special Service Tool: 09023-38401 to remove the turn pressure tube assembly with both O-rings present. Stabilize the power steering rack and pinion assembly inside the vise through usage of Special Service Tools 09612-00012 and 90105-10346. Mark the positions for reassembly after removing the tie rod end sub-assemblies from both the left and right sides. Use caution to protect boot appearance while selectively loosening and removing clamps and rack boots along with the clips. Users must unstake the washer at the steering rack end using a screwdriver and hammer before handling the steering rack steady for removal with Special Service Tool: 09922-10010. Use a hexagon wrench to remove the rack guide spring cap lock nut followed by its components of rack guide spring cap and spring and sub-assembly. You can remove the rack housing cap by using Special Service Tool: 09816-30010 and stop the control valve shaft rotation with Special Service Tool: 09616-00011 before removing the self-locking nut. First reinstall the control valve housing then carefully mark the assembly positions before proceeding with removal of the dust cover along with the control valve assembly from the housing. Press the valve assembly with its attached oil seal through a careful press action without damaging the lip of the oil seal. Extract the oil seal and cylinder end stopper by employing Special Service Tool: 09631-16010. Evacuate the steering rack and pinion with bushing from its mount using Special Service Tool: 09950-70010 (09951-07200) to extract its O-ring material. Measure the runout and wear of the steering rack and pinion with a dial indicator to check that maximum deviation reaches 0.09 mm (0.0035 inch). Fit the bearing and install the oil seal by using Special Service Tool: 09950-60010 (09951-00250) and 09950-70010 (09951-07150) while making sure to set the oil seal in its right installation direction. Install the steering rack and pinion's new O-ring by applying power steering fluid onto it first and then add the teflon ring. The reassembly process requires coating all parts with power steering fluid or molybdenum disulfide lithium base grease before installing the oil seal through Special Service Tool: 09950-60010 (09951-00330) and positioning the steering rack and pinion into the rack housing. The installation process should involve setting the bushing and cylinder end stopper with correct alignment. A vacuum test must be performed using Special Service Tool: 09631-12071 at 53 kPa (400 mmHg, 15.75 in.Hg) for exactly 30 seconds. The control valve housing and its oil seal must be installed with a new gasket along with matched alignment between references and bolt torque should meet manufacturer specs. Fix the self-locking nut combined with dust cover and rack housing cap using an appropriate sealant while achieving the required torque values. Install the rack guide sub-assembly together with spring and cap before adjusting total preload to according specifications. Place the rack end along with the claw washer before performing proper torque measurements and securing the washer with a stake. Install the rack boot together with its clamp and clip while checking for any obstruction within the steering rack and pinion hole. After adjustment of toe-in complete the installation of tie rod ends with lock nuts. Install the power steering rack and pinion assembly before establishing a connection between the return and pressure feed tube assemblies using Special Service Tool: 09023-12701 and then joining the clamp plate. The technician must position the spiral cable correctly and then add the steering wheel assembly while performing air bleeds on the power steering system. The technician checks the steering wheel position while tightening the wheel set nut to 50 Nm before installing the pad. The last steps involve checking the front wheel alignment followed by negative battery terminal reinstallation and execution of yaw rate and deceleration sensor zero point calibration procedures with mandatory initialization when required.