×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Avalon Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rack And Pinion found

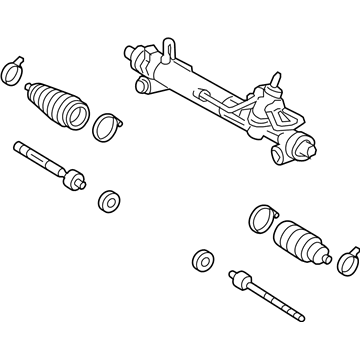

2006 Toyota Avalon Steering Gear

Part Number: 44250-07101$676.90 MSRP: $992.01You Save: $315.11 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly; Gear Assembly, Power Steering(For Rack & Pinion)

- Replaces: 44250-07100

- Part Name Code: 44250

- Item Weight: 22.30 Pounds

- Item Dimensions: 50.7 x 10.9 x 6.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44250-07101

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Avalon Rack And Pinion

Looking for affordable OEM 2006 Toyota Avalon Rack And Pinion? Explore our comprehensive catalogue of genuine 2006 Toyota Avalon Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Avalon Rack And Pinion Parts Q&A

- Q: How to overhaul the rack and pinion power steering gear assembly on 2006 Toyota Avalon?A: The first step in rack and pinion power steering rack and pinion assembly overhaul requires mounting the power steering control valve upper oil seal while applying SST 09950-70010 (09951-07150) and a press for installation with correct seal positioning. Place the control valve upper bearing into position with the aid of SST 09950-70010 (09951-07150). The process for control valve installation starts with expanding four new valve spacers followed by fluid coating before inserting them onto the control valve with any required adjustments. Insert SST 09631-20081 over the valve spacers carefully and position the control valve into the valve housing without harming the spacers or oil seal lip and apply power steering fluid to a new oil seal lip before using SST 09612-22011 for installation. First apply grease to the needle roller bearing of the rack housing and the serrated part of the control valve. Then use a new gasket to cover the control valve housing before installing and torquing 2 bolts to 20 Nm (204 kgf-cm, 15 ft. lbs.). When installing a new lock nut engineers should restrain the control valve from rotation with SST 09616-00011 and finalize installation by using a 27 mm socket wrench while applying sealant (Part No. 08833-00080, Three Bond 1344, Loctite 242 or equivalent) to 2 or 3 threads of the rack housing cap and torquing to 54 Nm (546 kgf-cm, 40 ft. lbs.) before staking with a punch and hammer. To install the rack guide begin by lubricating its contact area and inserting it with the compression spring followed by thread sealing the spring cap before performing the temporary fixture. The total preload adjustability requires installation of the RH and LH rack end sub-assembly with SST 09631-10021 torqued to 25 Nm (250 kgf-cm, 18 ft. lbs.) followed by loosening and valve control turning left and right before spring cap loosening when the spring stops working. Tighten the rack guide spring cap to attain a preload between 1.2 to 1.5 Nm (12.2 to 15.3 kgf-cm, 10.6 to 13.3 inch lbs.) while applying sealant to the lock nut threads and temporarily installing it with SST 09616-00011 and 09922-10010. After verifying the total preload you should eliminate the rack end sub-assembly before applying MP grease around the control valve shaft. Then place vinyl tape around the spline and finally put on the dust cover. The installation of the rack and pinion end sub-assembly requires two new claw washers which should fit properly into the rack grooves before installing them with SST 09922-10010 to a torque of 58 Nm (586 kgf-cm, 42 ft. lbs.) after hammer and brass bar staking. Check the power steering rack for obstructed holes then secure steering rack boot No. 2 with silicone grease applied to its tiny opening and inserted into the housing groove without causing damage. Repetitions for steering rack boot No. 1 require tightening boot clamps (SST 09521-24010) to create a 2.0 mm (0.079 inch) or less clearance before installing boot clips via pliers usage. The tie rod assembly left should be connected to the rack end with proper mark alignment followed by lock nut torque adjustment. The procedure must be repeated for the right-hand side tie rod assembly. Secure the left turn pressure tube through o-ring coating with power steering fluid and torque application of SST 09023-38201 at 11 Nm (113 kgf-cm, 8 ft. lbs.) while keeping the torque wrench parallel to the SST. Place the power steering rack housing heat insulator with care after both the left and right turn pressure tubes receive installation. The rack and pinion power steering rack and pinion assembly should be installed using 2 bolts and 2 nuts with final torque set at 70 Nm (714 kgf-cm, 52 ft. lbs.) and avoid twisting the nuts. Screw the pressure feed tube assembly together using SST 09023-12701 while maintaining a 22 Nm torque (227 kgf-cm, 16 ft. lbs.) and keeping the torque wrench aligned parallel to the SST before you proceed to install the return tube assembly the same way. The pressure feed tube should be clamped in place using two bolts which require a 9.8 Nm (100 kgf-cm, 87 inch lbs.) torque setting before front stabilizer bracket installation through each of the two bolts, also with a torque setting of 19 Nm (194 kgf-cm, 14 ft. lbs.). After connecting the tie rod assembly LH to the steering knuckle with the castle nut the technician torques it to 49 Nm (500 kgf-cm, 36 ft. lbs.) before installing a new cotter pin that requires additional nut tightening if needed. This sequence is repeated for the RH side. The repetitive steps on the RH side involve matching the steering intermediate shaft bolt matchmarks before torquing it to 35 Nm (360 kgf-cm, 26 ft. lbs.). After bleeding the power steering fluid the technician should check for leaks and finally install the front fender apron seals LH and RH before torquing the front wheel to 103 Nm (1,050 kgf-cm, 76 ft. lbs.). Front wheel alignment must be checked as the final step.