×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota 4Runner Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rack And Pinion found

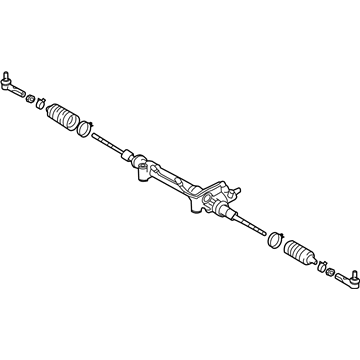

2006 Toyota 4Runner Steering Gear

Part Number: 44200-35070$976.36 MSRP: $1430.87You Save: $454.51 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Link Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly

- Part Name Code: 44200

- Item Weight: 49.50 Pounds

- Item Dimensions: 52.7 x 11.1 x 6.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44200-35070

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota 4Runner Rack And Pinion

Looking for affordable OEM 2006 Toyota 4Runner Rack And Pinion? Explore our comprehensive catalogue of genuine 2006 Toyota 4Runner Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota 4Runner Rack And Pinion Parts Q&A

- Q: How to Overhaul a Power Rack and Pinion Assembly on 2006 Toyota 4Runner?A: The power steering control valve upper oil seal installation process begins with applying power steering fluid to the lip of the new seal before pressing it in using tool set Special Service Tool: 09950-60010 (09951-00180, 09951-00320, 09952-06010) and 09950-70010 (09951-07150). Use Special Service Tool: 09950-60010 (09951-00180, 09951-00320, 09952-06010) and 09950-70010 (09951-07150) to press newly coated molybdenum disulfide lithium base grease bearing into place. Before mounting the power steering control valve users should tap gently on a new union seat with a plastic hammer and apply power steering fluid to the rings before expanding and placing all four rings on the control valve assembly. The rings need Special Service Tool: 09631-20081 for sliding over them while maintaining correct expansion and receiving power steering fluid coating on the Teflon rings. Before inserting the valve assembly into the housing it is necessary to protect the oil seal lip by wrapping vinyl tape around the shaft's serrated port. Use a hammer to drive in the oil seal lip together with the new O-ring using Special Service Tool: 09950-60010 (09951-00390), 09950-70010 (09951-07100) while guaranteeing proper orientation. Secure the control valve assembly inside a vise and wrap tape around the pinion section of the control valve shaft before tightening the guide nut to 25 Nm through the use of Special Service Tool: 09631-20060. Perform this operation with caution to avoid oil seal lip damage. The bearing guide nut requires a punch along with a hammer to stake it in place yet a new O-ring needs power steering fluid application before installing it to the nut. The control valve assembly requires 2 g (0.07 oz.) of molybdenum disulfide base grease application to the needle roller bearing inside the rack housing before installation with two bolts that need torquing to 18 Nm (184 kgf-cm, 13 ft. lbs.). Use a 24 mm hexagon wrench to install the rack guide and spring but only after adding Part No. 08833-00080 (Three Bond 1344, Loctite 242 or equivalent) to 2 or 3 threads of the rack guide spring cap then tighten it to 25 Nm (250 kgf-cm, 18 ft. lbs.) before returning the cap 30 degrees. Special Service Tool: 09616-00011 should be used to rotate the control valve shaft followed by loosening the cap until the rack guide spring stops engaging. With a torque range between 1.35 Nm to 1.55 Nm tighten the cap before installing it temporarily along with application of sealant to the lock nut threads. Apply Special Service Tool: 09922-10010 when torquing the nut to 65 Nm (660 kgf-cm, 48 ft. lbs.) while using the tool in the specified direction. Verify the rack total preload measurement between 0.7 to 1.5 Nm before removing the rack ends. The power steering rack should be checked for blockage by using a wire in the vent hole. Installation of the rack end sub-assembly requires a new claw washer together with torqueing the rack end LH to 98 Nm (1,000 kgf-cm, 72 ft. lbs.) through Special Service Tool: 09922-10010 before repeating for the RH side. Position the washer with a brass bar before using a hammer to stake it while keeping the rack free from impact. Mount the rack boots to both sides of the assembly and fasten the clamps and clips while protecting their shape. The power steering rack assembly requires inspection by using Special Service Tool: 09616-00011 while you apply MP grease to all components followed by dust cover installation. Connect the steering turn pressure tubes using Special Service Tool: 09023-38200 and torque them to 23 Nm (230 kgf-cm, 17 ft. lbs.). Then install the tie rod end sub-assemblies while torquing their nuts to 88 Nm (897 kgf-cm, 65 ft. lbs.). Fasten the power steering link assembly using two bolts and nuts before torquing them to 100 Nm (1,020 kgf-cm; 74 ft. lbs.) while you should rotate the bolt not the nut. The outlet return tube must be attached using Special Service Tool: 09023-12700 while torqueing to 40 Nm (410 kgf-cm, 30 ft. lbs.) followed by installation of the pressure feed tube assembly at 28 Nm (286 kgf-cm, 21 ft. lbs.). Finally, the flare nut needs a torque of 40 Nm (410 kgf-cm, 30 ft. lbs.). Install the engine under covers together with their specified bolts then secure the tie rod ends to the steering knuckle arms while fully tightening the steering intermediate shaft sub-assembly No.2. The last task involves installing front wheels that must point forward straight ahead before moving onto the turn signal switch assembly followed by the spiral cable sub-assembly and steering column cover and steering wheel assembly. During installation check the steering wheel center point as well as the horn button assembly and SRS warning light and perform power steering fluid addition and bleeding followed by leak checks and front wheel alignment inspection.