×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota MR2 Spyder Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter Motor found

- Product Specifications

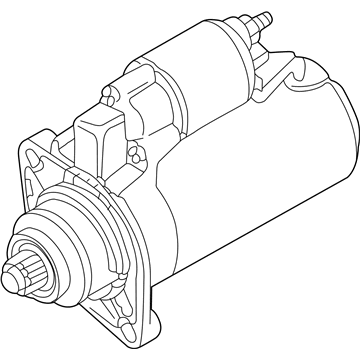

- Other Name: Reman Starter Assembly; Starter Motor

- Replaces: 28100-22060

- Item Weight: 9.30 Pounds

- Item Dimensions: 10.3 x 7.1 x 5.1 inches

- Condition: New

- SKU: 28100-22060-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota MR2 Spyder Starter Motor

Looking for affordable OEM 2004 Toyota MR2 Spyder Starter Motor? Explore our comprehensive catalogue of genuine 2004 Toyota MR2 Spyder Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota MR2 Spyder Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2004 Toyota MR2 Spyder?A: Start the procedure of repairing the starter motor by taking the following steps: disconnect the lead wire from the magnetic switch terminal then remove 2 through bolts and pull out the field frame with armature from the magnetic switch assembly. Initiate field frame servicing by taking out first the O-ring then the 2 screws together with end cover and finally the O-ring from the field frame. First engage the screwdriver to disconnect the brush from the brush holder and position the spring tank backward. After this disconnect the brush from its holder and remove all four brushes along with the holder. Detach the starter housing and clutch assembly and gears by removing the 2 bolts and extracting these components: starter housing (1), idler gear (2), bearing (3), clutch assembly (4) and return spring (5) from the magnetic switch assembly. A magnetic finger tool should be used to bring out the steel ball from the clutch shaft opening. Users must employ Special Service Tool: 09286-46011 to remove bearings before pressing in new front and rear bearings through Special Service Tool: 09820-00031 using a press. The processor requires a new magnetic switch terminal kit by removing the three bolts followed by unfastening the end cover and gasket and plunger from the assembly. Inspect the contact plate wear by measuring its depth to confirm it does not surpass 0.9 mm (0.035 in.). Special Service Tool: 09810-38140 removes terminal nuts through Special Service Tool: 09810-38140 to access Terminal C and Terminal 30 as documented in the instructions for removal. The new terminal 30 kit parts need temporary installation with correct terminal insulator positioning before tightening the nuts. A wooden block (20 x 37 x 40 mm) should apply 981 N (100 kgf, 221 lbf) of force against the contact plate before the nuts are tightened to 17 N.m (170 kgf.cm, 12 ft.lbf) using Special Service Tool: 09810-38140. Install the magnetic switch end cover after cleaning contact surfaces by putting in the plunger and 3 bolts with new gasket and torquing them to 2.5 N.m (26 kgf.cm, 23 in.lbf). The reassembly process starts with high-temperature grease lubrication of bearings and gears before installing the armature to the magnetic switch assembly while placing the steel ball inside the clutch shaft hole and finishing with starter housing installation followed by clutch assembly and gears using grease on the return spring before torquing the starter housing to 5.9 N.m (60 kgf.cm, 52 in.lbf). Fitting a new O-ring to the field frame requires proper alignment of its magnetic switch before installation. Position the brush holder onto the field frame then attach the brushes before applying a new O-ring to the end cover while tightening its 2 screws to 1.5 N.m (15 kgf.cm, 13 in.lbf). The installation process requires two through bolts on the field frame and armature assembly to be torqued to 5.9 N.m (60 kgf.cm, 52 in.lbf). Then, connect the lead wire to terminal C by nutting it to 5.9 N.m (60 kgf.cm, 52 in.lbf). Finish with a new dust protector installation.