×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota Matrix Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Rack And Pinions found

2004 Toyota Matrix Steering Gear

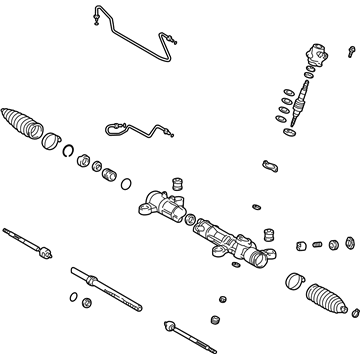

Part Number: 44250-01021$653.07 MSRP: $957.08You Save: $304.01 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly; Gear Assembly, Power Steering(For Rack & Pinion)

- Replaces: 44250-01020

- Part Name Code: 44250

- Item Weight: 14.40 Pounds

- Item Dimensions: 56.5 x 11.2 x 7.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44250-01021

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Matrix Steering Gear

Part Number: 44250-01041$634.05 MSRP: $928.99You Save: $294.94 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly; Gear Assembly, Power Steering(For Rack & Pinion)

- Replaces: 44250-01040

- Part Name Code: 44250

- Item Weight: 17.10 Pounds

- Item Dimensions: 49.2 x 10.6 x 6.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44250-01041

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

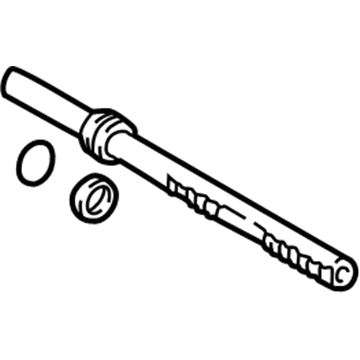

- Product Specifications

- Other Name: Rack Sub-Assembly, Power; Steering Gearbox; Steering Rack; Rack Sub-Assembly, Power Steering

- Part Name Code: 44204

- Item Weight: 5.70 Pounds

- Item Dimensions: 32.4 x 3.1 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44204-02060

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Matrix Rack And Pinion

Looking for affordable OEM 2004 Toyota Matrix Rack And Pinion? Explore our comprehensive catalogue of genuine 2004 Toyota Matrix Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota Matrix Rack And Pinion Parts Q&A

- Q: What Are the Complete Procedures and Safety Precautions for Disassembling, Inspecting, and Reassembling the Power Rack And Pinion Assembly with Proper Torque Specifications on 2004 Toyota Matrix?A: Apply power steering fluid or molybdenum disulfide lithium base grease to the parts as marked by the arrow during installation process. The technician should disconnect the battery negative terminal then inspect the center front wheel before disassembling the horn button assembly and steering wheel assembly with SST 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021). To start the installation process remove the front wheels and engine under covers from both sides of the vehicle and disconnect the tie rod end sub-assembly LH with SST 09628-62011 by removing the cotter pin and nut. Repeat for the RH side. The maintenance process begins by taking off the column hole cover silencer sheet followed by disconnecting the steering intermediate shaft and pressure feed tube assembly that uses SST 09023-38400 while returning to disconnect the return tube sub-assembly with the same SST to remove the bolt and tube clamp. The 4WD procedure includes disconnecting the clamp after removing its bolt. Lift and separate the front stabilizer link assemblies LH and RH before disconnecting the front suspension arm sub-assembly lower No.1 LH by removing its bolt and 2 nuts. Repeat this process on the RH side. The hood sub-assembly and cylinder head cover No.2 should be removed while installing the 2 engine hangers with bolts for direction guidance before attaching the engine chain hoist to suspend the engine assembly. To remove the front suspension crossmember sub-assembly disconnect it from the engine mounting insulator FR and the frame when supported by a transmission jack and at this time remove the bolts. Start by removing the steering column hole cover sub-assembly No.1 followed by the steering intermediate shaft after applying matchmarks and the rack and pinion power steering assembly by unbolt its components. Apply SST 09612-00012 to the rack and pinion power steering assembly before fixing it in a vise. Then use SST 09023-38200 to remove the left and right turn pressure tubes alongside their O-rings. Inspection of the LH tie rod end sub-assembly involves attaching it to a vise and tightening the stud bolt nut before flipping the ball joint stud back and forth to measure torque at the fifth turn within 0.49-3.43 Nm (5.0-35 kgf-cm, 4.34-30.38 inch lbs.). Use a spanner combined with SST 09922-10010 to uninstall the steering rack end sub-assembly after removing steering rack boots No.1 and No.2 while marking the RH and LH rack ends. First use SST 09922-10010 to eliminate the rack guide then remove the power steering control valve after taking away the rack housing cap while holding the control valve shaft with SST 09616-0011 to remove all bolts and gasket. Bind the control valve serrated area with vinyl tape to protect the oil seal lips before taking out the control valve and its oil seal together. Carefully separate the power steering control valve rings to protect the valve grooves from damage. To take out the upper oil seal from the power steering control valve SST 09950-70010 (09951-07150) serves alongside SST 09950-60010 (09951-00260) while snap ring pliers will remove the cylinder end stopper. Very carefully remove the power steering rack by pulling out the cylinder end stopper combined with SST 09612-24014 (09612-10061) while avoiding any drops. Extract the O-ring from the bushing after completing the procedure. To disconnect the power steering rack bush sub-assembly and the power steering cylinder tube oil seal use SST 09950-60010 (09951-00260), 09950-70010 (09951-07360). SST 09950-70010 (09951-07100) can be used to remove the power steering control valve lower bearing and center bearing. Test the power steering rack for its run out condition as well as teeth wear while maintaining maximum run out to 0.1 millimeters (0.004 inches). Insert the power steering control valve lower bearing and upper oil seal into their positions by applying molybdenum disulfide lithium base grease and power steering fluid on them respectively. The power steering rack installation requires the power piston O-ring and oil seal to have proper coating coverage while they settle. Proceed with the power steering rack bush sub-assembly installation by positioning the oil seal correctly before inserting the cylinder end stopper with SST 09612-22011 then securing it with the snap ring. Check how the rack and pinion power steering assembly operates under vacuum conditions by applying artificial vacuum. Position the power steering control valve before sliding the tapered end of SST over the control valve rings with expanded positions that are already coated with power steering fluid. Put the control valve into the valve housing while positioning the oil seal with the proper direction and lubricate the needle bearing before placing a fresh gasket. First wind vinyl tape around the serrated part of the control valve before you install the valve housing to the rack housing with bolts using the specified torque. First attach the rack guide followed by lubricating its contact surfaces with molybdenum disulfide lithium base grease before putting on the rack guide spring cap. The full preload should get checked by installing temporary RH and LH rack ends followed by torquing the rack guide spring cap and required adjustments. Place the steering rack end sub-assembly while verifying the steering rack hole remains clean from grease and add the steering rack boots No.1 and No.2 then tighten them using SST 09521-24010. Install the steering right and left turn pressure tubes while applying new O-rings with power steering fluid through SST 09023-38200 before finishing both RH and LH tie rod end sub-assemblies. Check toe-in by torquing the lock nuts after adjustment. Securing 4WD bush installation requires proper torque on the rack and pinion power steering assembly installation. The steering intermediate shaft installation requires precise mark alignment before fastening the bolt with proper torque. The service process includes installation of the steering column hole cover sub-assembly No.1 followed by the front suspension crossmember sub-assembly and proper torque application between the engine mounting insulator RR and FR. The lower section of front suspension arm sub-assemblies No.1 LH and RH must be connected together as well as front stabilizer link assemblies LH and RH. Use SST 09023-38400 to connect the return and pressure feed tube sub-assemblies following the specified torque requirements. Use new cotter pins to join steering intermediate shaft and tie rod end sub-assemblies on both the left hand (LH) and right hand (RH) sides. Install engine covers LH and RH and tighten the front wheels with specified torque before checking the center front wheel position. The service technician should install the column hole cover silencer sheet followed by power steering fluid addition and power steering fluid bleeding and fluid leak examinations. The last step includes installing cylinder head cover No.2 together with the hood sub-assembly and conducting checks and corrections on the hood sub-assembly as well as the center spiral cable, steering wheel assembly and front wheel alignment systems followed by SRS warning light inspection.