×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota Land Cruiser Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Coil Springs found

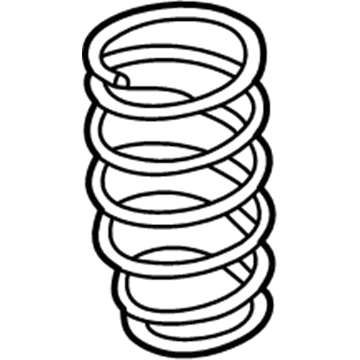

2004 Toyota Land Cruiser Coil Spring, Rear Driver Side

Part Number: 48231-6A690$253.84 MSRP: $362.42You Save: $108.58 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spring, Coil, Rear; Coil Spring, Rear Left; Coil Spring Rear; Coil Springs; Spring; Spring, Coil, Rear Driver Side

- Manufacturer Note: H=504,GREEN & PINK PAINTED

- Position: Rear Driver Side

- Part Name Code: 48231B

- Item Weight: 18.00 Pounds

- Item Dimensions: 18.1 x 11.1 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48231-6A690

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Land Cruiser Coil Spring, Rear Passenger Side

Part Number: 48231-6A680$247.90 MSRP: $353.95You Save: $106.05 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spring, Coil, Rear; Coil Spring, Rear Right; Coil Springs; Spring; Spring, Coil, Rear Passenger Side

- Manufacturer Note: H=498,GREEN&GREEN PAINTED

- Position: Rear Passenger Side

- Part Name Code: 48231A

- Item Weight: 17.40 Pounds

- Item Dimensions: 17.9 x 11.7 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48231-6A680

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Land Cruiser Coil Spring, Rear Passenger Side

Part Number: 48231-6A770$126.89 MSRP: $179.63You Save: $52.74 (30%)Product Specifications- Other Name: Spring, Coil, Rear; Coil Springs; Spring; Spring, Coil, Rear Passenger Side

- Manufacturer Note: W(ACTIVE HEIGHT CONTROL);H=485,PURPLE PAINTED

- Position: Rear Passenger Side

- Part Name Code: 48231A

- Item Weight: 5.10 Pounds

- Item Dimensions: 17.9 x 11.3 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48231-6A770

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Land Cruiser Coil Springs

Looking for affordable OEM 2004 Toyota Land Cruiser Coil Springs? Explore our comprehensive catalogue of genuine 2004 Toyota Land Cruiser Coil Springs. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota Land Cruiser Coil Springs Parts Q&A

- Q: How to service the coil springs and rear shock absorber on 2004 Toyota Land Cruiser?A: The first step for servicing the coil spring and rear shock absorber requires wheel removal at 131 Nm (1,340 kgf-cm, 97 ft. lbs.). The process begins with securing the rear axle housing using a jack and continuing by removing the shock absorber after unbolt the housing with 98 Nm (1,000 kgf-cm, 72 ft. lbs.) torque and repeating the procedure on the other side. The service process requires you to hold the piston rod steady during removal of the nut and two retainers together with a cushion and shock absorber which requires a torque of 69 Nm (704 kgf-cm, 51 ft. lbs.). Post-nut removal you should remove the two retainers and cushion from the shock absorber. It is necessary to disconnect the LH and RH stabilizer bar brackets by removing 4 bolts that require 18 Nm (185 kgf-cm, 13 ft. lbs.) torque setting and then disconnect the lateral control rod which requires a 150 Nm (1,530 kgf-cm, 111 ft. lbs.) torque setting application of bolt, washer and nut. Post-stabilization of the suspension it is essential to torque the nut and bolt for installation Start by disconnecting the breather hose before lowering the axle housing at a controlled pace because you must prevent damage to either the brake line or parking brake cable. Remove the coil spring and insulator afterward. Confirmation of proper coil spring end installation needs to be done before replacing it if incorrect. Begin by torqueing the bolt and follow spring from the frame to 28 Nm (290 kgf-cm, 21 ft. lbs.). To inspect the shock absorber properly extend and compress its rod until you notice irregular resistance or strange sounds because any detected abnormalities should trigger a replacement. To dispose of the shock absorber make a 2 - 3 mm (0.079 - 0.118 inch) diameter hole to release its internal gas while being cautious of little chips that may escape since the gas has no color, odor, and is harmless. Use 09710-00061 & 09710-07031 and 09951-07100 along with 09710-14013 then 09710-28012 through a press for bushing removal and installation that should proceed in the opposite direction of removal.