×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Tacoma Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Ball Joints found

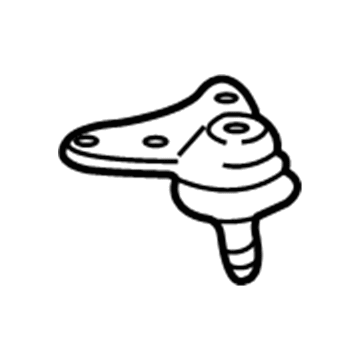

2003 Toyota Tacoma Lower Ball Joint, Driver Side

Part Number: 43340-39585$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Driver Side

- Replaces: 43340-39287, 43340-39286

- Item Weight: 8.80 Pounds

- Item Dimensions: 5.5 x 3.4 x 2.4 inches

- Condition: New

- SKU: 43340-39585

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Lower Ball Joint, Passenger Side

Part Number: 43330-39815$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Passenger Side

- Replaces: 43330-39366, 43330-39367

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.3 x 3.2 x 2.5 inches

- Condition: New

- SKU: 43330-39815

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

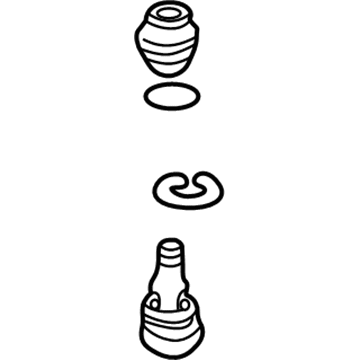

2003 Toyota Tacoma Upper Ball Joint, Front

Part Number: 43310-39016$49.94 MSRP: $69.51You Save: $19.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Upper; Upper Ball Joints; Front Upper Ball Joint Assembly for Driver & Passenger Side.

- Position: Front Upper

- Replaces: 43310-39085, 43310-39065

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.5 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43310-39016

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Lower Ball Joint, Front Passenger Side

Part Number: 43330-39556$134.88 MSRP: $190.93You Save: $56.05 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39555

- Part Name Code: 43330K

- Item Weight: 1.50 Pounds

- Item Dimensions: 5.4 x 3.2 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43330-39556

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Lower Ball Joint, Front Driver Side

Part Number: 43340-39436$117.66 MSRP: $165.16You Save: $47.50 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Joint Assembly, Lower Ball, Front Driver Side; Suspension Ball Joint; Ball Joint

- Position: Front Driver Side

- Replaces: 43340-39435

- Part Name Code: 43340A

- Item Weight: 5.20 Pounds

- Item Dimensions: 5.4 x 3.4 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43340-39436

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Lower Ball Joint, Front Passenger Side

Part Number: 43330-39565$93.25 MSRP: $130.89You Save: $37.64 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39355

- Part Name Code: 43330K

- Item Weight: 3.00 Pounds

- Item Dimensions: 5.4 x 3.2 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43330-39565

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

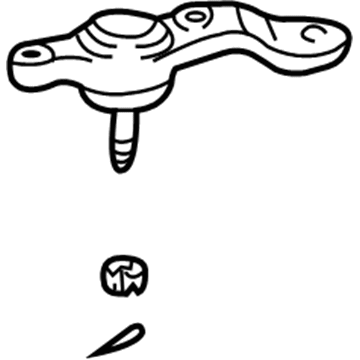

2003 Toyota Tacoma Lower Ball Joint, Front Driver Side

Part Number: 43340-39445$73.70 MSRP: $103.44You Save: $29.74 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Left Lower; Joint Assembly, Lower Ball, Front Driver Side; Suspension Ball Joint; Ball Joint

- Position: Front Driver Side

- Replaces: 43340-39275

- Part Name Code: 43340A

- Item Weight: 2.90 Pounds

- Item Dimensions: 5.4 x 3.3 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43340-39445

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

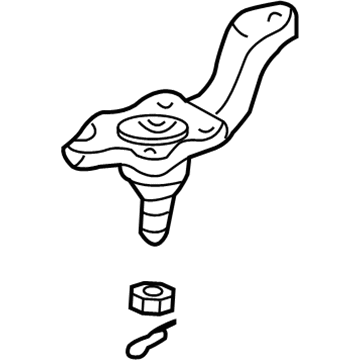

2003 Toyota Tacoma Upper Ball Joint, Driver Side

Part Number: 43360-39095$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Left Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Driver Side; Suspension Ball Joint; Ball Joint

- Position: Driver Side

- Part Name Code: 43360

- Item Weight: 1.90 Pounds

- Item Dimensions: 7.1 x 4.6 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43360-39095

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

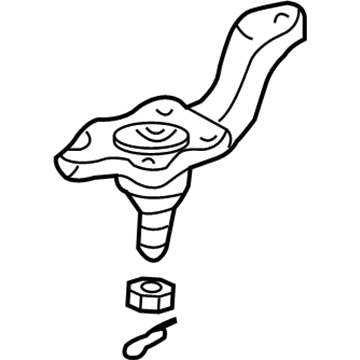

2003 Toyota Tacoma Upper Ball Joint, Passenger Side

Part Number: 43350-39105$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper B; Suspension Ball Joint, Front Right Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Passenger Side

- Part Name Code: 43350

- Item Weight: 1.90 Pounds

- Item Dimensions: 5.3 x 3.7 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43350-39105

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Ball Joint

Looking for affordable OEM 2003 Toyota Tacoma Ball Joint? Explore our comprehensive catalogue of genuine 2003 Toyota Tacoma Ball Joint. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Tacoma Ball Joint Parts Q&A

- Q: How to service and repair the upper ball joint on 2003 Toyota Tacoma?A: Service and repair operations for the upper ball joint must be applied to the specified models RZN191L-TRPDKAB, RZN196L-CRPDKAB, PZN196L-PRPDKAB, VZN195L-CRPDKAB and VZN195L-PRPDKAB starting with the removal of the steering knuckle with its axle hub. A correct torque value of the nut lies between 0.7 - 4.4 Nm (7 - 45 kgf-cm, 6 - 39 inch lbs.) which needs to be reached during a continuous movement of the nut for one full turn performed every 2 to 4 seconds. This torque check should occur on the fifth motion of nut rotation. Start ball joint replacement by disassembling the upper ball joint components through boot and wire removal followed by snap ring removal using snap ring expander tools and then using Special Service Tool: 09950-40011 combined with other tools to extract the ball joint. Install the new upper ball joint by using Special Service Tool: 09309-37010 with a socket wrench followed by installing a new snap ring using the snap ring expander and subsequently positioning a new boot with a new wire and complete the procedure with grease provided in the kit. Ending the process requires you to reinstall the steering knuckle together with the axle hub.