×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Land Cruiser Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rack And Pinions found

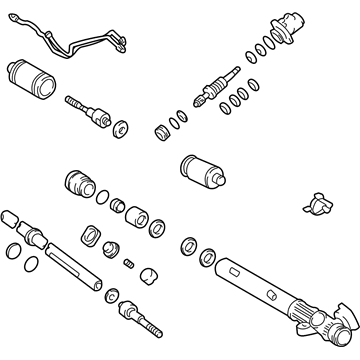

2002 Toyota Land Cruiser Gear Assembly, Power Steering(For Rack & Pinion)

Part Number: 44250-60050$685.64 MSRP: $1004.81You Save: $319.17 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox

- Part Name Code: 44250

- Item Weight: 40.80 Pounds

- Item Dimensions: 48.8 x 9.5 x 8.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44250-60050

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

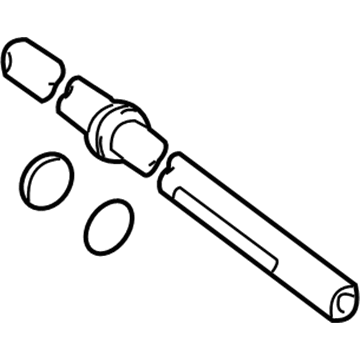

2002 Toyota Land Cruiser Rack, Front

Part Number: 44204-60020$389.74 MSRP: $571.17You Save: $181.43 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rack Sub-Assembly, Power; Rack And Pinion Rack Gear, Front; Steering Gearbox; Steering Rack; Rack Sub-Assembly, Power Steering

- Position: Front

- Part Name Code: 44204

- Item Weight: 5.40 Pounds

- Item Dimensions: 33.1 x 3.3 x 2.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44204-60020

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Land Cruiser Rack And Pinion

Looking for affordable OEM 2002 Toyota Land Cruiser Rack And Pinion? Explore our comprehensive catalogue of genuine 2002 Toyota Land Cruiser Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Land Cruiser Rack And Pinion Parts Q&A

- Q: How to remove and install the Rack And Pinion on 2002 Toyota Land Cruiser?A: You must start by aligning the front wheels forward before removing the steering wheel pad and steering wheel. Begin by lifting off the No. 1 engine under cover through bolt removal of seven pieces followed by performing the same procedure to remove the No. 2 engine under cover. The engine oil filter assembly is removed by disconnecting two clips with hoses followed by removing two bolts and a nut and bracket as well as O-ring and the engine oil filter. To separate the No. 2 intermediate shaft assembly rotate the steering wheel completely to the right side until you can disconnect the pressure feed tube by uninstalling its union bolt and gasket. Disengage the return tube using Special Service Tool: 09023-38400. The bracket and grommet assembly can be removed when you detach 2 bolts on the system. After that disconnect the tube clamp by removing its bolt. Begin by mark-aligning the tie rod end together with its lock nut and rack end. Then loosen the lock nut and take out the tie rod end. The Rack And Pinion assembly requires 2 bolts removal alongside 2 nuts and 2 washers before removal. To install the Rack And Pinion assembly first install two bolts and two nuts together with two washers before torquing the assembly to 100 Nm (1,020 kgf-cm, 74 ft. lbs.). After aligning the matchmarks between tie rod end and lock nut, install them on the vehicle then torque both nuts to 55 Nm (560 kgf-cm, 41 ft. lbs.). Install the tube clamp through a bolt tightened to 18 Nm (180 kgf-cm, 13 ft. lbs.) and follow it up with installation of the grommet and bracket with 2 new bolts torqued to 100 Nm (1,020 kgf-cm, 74 ft. lbs.). Use Special Service Tool: 09023-38400 to connect the return tube at 50 Nm (510 kgf-cm, 37 ft. lbs.) torque when the tool reaches a 300 mm (11.81 inch) fulcrum length and remains parallel to the tool. You should attach the pressure feed tube by putting a new gasket on the union bolt then torquing it to 42 Nm (430 kgf-cm, 31 ft. lbs.). The installation of engine oil filter assembly starts with adding a new O-ring followed by securing it with 2 bolts and a nut torqued to 18 Nm (180 kgf-cm, 13 ft. lbs.), then reconnect both hoses and clips. Next, attach the No. 2 intermediate shaft assembly. The RH and LH tie rod ends can be reconnected while installing the No. 2 engine under cover with 6 bolts and the No. 1 engine under cover with 7 bolts. Align the front wheels at 0 degrees and place the spiral cable at the center. Then install the steering wheel using matchmarks while tightening the set nut temporarily before connecting the connector. The power steering braking process should be completed before checking the steering wheel positioning for center alignment. Torque the steering wheel nut to 50 Nm while installing the pad and performing front wheel alignment verification.