×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Land Cruiser Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rack And Pinion found

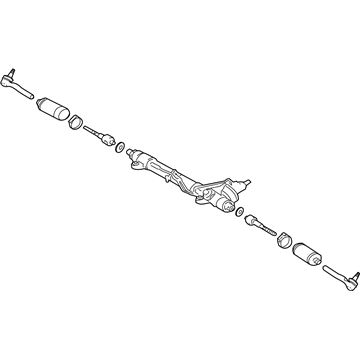

2003 Toyota Land Cruiser Link Assembly, Power Steering

Part Number: 44200-60100$680.83 MSRP: $997.77You Save: $316.94 (32%)Product Specifications- Other Name: Rack and Pinion Assembly; Steering Gearbox

- Part Name Code: 44200

- Item Weight: 38.20 Pounds

- Item Dimensions: 52.2 x 11.0 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44200-60100

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Land Cruiser Rack And Pinion

Looking for affordable OEM 2003 Toyota Land Cruiser Rack And Pinion? Explore our comprehensive catalogue of genuine 2003 Toyota Land Cruiser Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Land Cruiser Rack And Pinion Parts Q&A

- Q: How to service and repair the Rack And Pinion on 2003 Toyota Land Cruiser?A: The Rack And Pinion assembly service and repair process starts with vise attachment using Special Service Tool: 09630-00014 (09631-00142) where you must avoid tight clamping. First use Special Service Tool: 09023-38200 to detach the 2-turn pressure tubes from their respective locations before unclamping the RH and LH clips rack boots and clamps with pliers while maintaining care for the intact boots. After marking the RH and LH parts for later use unfasten the clips and rack boots and clamps from the rack and pinion assembly. Stake the claw washers with a screwdriver and hammer while avoiding the rack and pinion. Either a spanner or a wrench can be used to stabilize the rack and pinion before removing its ends using Special Service Tool: 09922-10010 while making sure to note the positions of the RH and LH rack ends. To start, remove the rack guide spring cap lock nut then the rack guide spring cap and afterward the rack guide spring and rack guide sub-assembly before taking off the dust cover. Place matchmarks on the control valve housing with control valve assembly before you remove the two bolts to pull the assembly out and remove the O-ring. Before valve assembly extraction use Special Service Tool: 09631-20060 to loosen the bearing guide nut and wrap the control valve shaft with vinyl tape before using a plastic hammer. Make sure to avoid damaging the oil seal lip during this process. Disassemble the valve assembly by removing its nut and O-ring, followed by separating cylinder end stopper and spacer with Special Service Tool: 09922-10010 as well as O-ring from stopper. Use Special Service Tool: 09950-70010 (09951-07200) to extract the rack along with its oil seal while keeping the rack from falling and then remove the oil seal from the rack. Examine the rack and pinion for runout and wear parameters while ensuring maximum runout measures lower than 0.03 mm (0.0118 inch). Also inspect the bearing for damage then apply molybdenum disulfide lithium base grease as required. Special Service Tools 09950-60010 (09951-00260) and 09950-70010 (09951-07150) should be used to perform the replacement with proper directional installation of the oil seal. Replace the bushing when there are signs of cracking while applying grease to its interior space. During the rack and pinion assembly the Teflon ring and O-ring should be exchanged and installed without damaging the rack and pinion groove structure. The replacement of Teflon rings should involve Special Service Tool 09631-20081 to correctly position new rings onto the rack and pinion. You should remove and install another union seat to the control valve housing if necessary. When reinstalling the components apply power steering fluid together with lithium base grease molybdenum disulfide to the indicated sections followed by installation of the rack and pinion with tool number 09631-00350 while double-checking the seal position. The spacer and cylinder end stopper installation requires torqueing to 110 Nm (1,122 kgf-cm, 81 ft. lbs.) through the utilization of Special Service Tool: 09922-10010 and then conducting an air tightness test with Special Service Tool: 09631-12071. Coat the Teflon rings before installing the control valve assembly and take measures to protect them from installation-related harm. The bearing guide nut requires torqueing to 24.5 Nm while stake operations secure the nut into place. The control valve housing receives the valve assembly then both bolts receive 18 Nm torque (180 kgf-cm, 13 ft. lbs.) after which the dust cover and rack guide sub-assembly along with rack guide spring and rack guide spring cap secured with sealant get installed. total preload adjustment requires the rack and pinion teeth to avoid damaging the oil seal lip before torquing the rack guide spring cap lock nut to 52 Nm (520 kgf-cm, 38 ft. lbs.) while validating total preload measurements. Complete the installation by torquing the rack ends to 99 Nm (1,014 kgf-cm, 74 ft. lbs.) and staking the washer followed by the installation of rack boots and clamps with clips before placing 2 turn pressure tubes (TORQUE 23 Nm (230 kgf-cm, 17 ft. lbs.) on the tube hole.