×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Avalon Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter Motor found

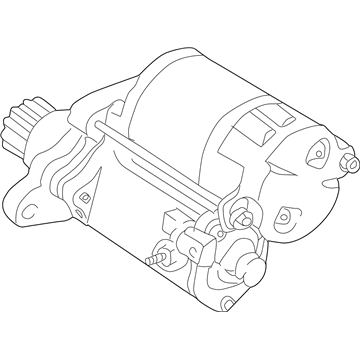

2002 Toyota Avalon Starter Assembly

Part Number: 28100-74260-84$158.04 MSRP: $222.38You Save: $64.34 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: REMAN STARTER ASSY; Starter Motor; Starter

- Replaces: 28100-03100, 28100-74260

- Item Weight: 15.60 Pounds

- Item Dimensions: 13.8 x 6.5 x 6.3 inches

- Condition: New

- SKU: 28100-74260-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Avalon Starter Motor

Looking for affordable OEM 2002 Toyota Avalon Starter Motor? Explore our comprehensive catalogue of genuine 2002 Toyota Avalon Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Avalon Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2002 Toyota Avalon?A: Service and repair of the starter motor requires starting with dust protector removal followed by disconnecting the lead wire from the magnetic switch terminal before removing the two through bolts with 5.9 N.m (60 kgf.cm, 52 in.lbf) torque. Remove the field frame together with armature and then align the protruding field frame portion to the magnetic switch indentation before removing the O-ring using a new ring for installation. Two screws securing the starter housing, clutch assembly, and gear need to be unscrewed using 5.9 N.m (60 kgf.cm, 52 in.lbf) torque for removal of these components. Afterward, the return spring, idler gear, and bearing can be separated. The removal process involves using a magnetic finger to obtain the steel ball from the clutch shaft hole prior to taking out the brush holder through screw disassembly of two screws and disassembling the end cover from the field frame with 1.5 N.m (15 kgf.cm, 13 in.lbf) torque followed by O-ring removal and brush detachment from the brush holder. The procedure for reassembly follows the original steps but involves applying high-temperature grease for lubrication of bearings as well as springs and steel ball and gears. You must begin the replacement process by inserting a brass bar into a vice and then push down the pinion gear until you tap down the stop collar to pry out the snap ring and complete the removal of the stop collar, pinion gear, and compression spring. The reassembly process starts with attaching the compression spring to the starter clutch followed by fixing the clutch shaft and then the starter clutch onto the starter housing while performing the exact steps for installing the stop collar and snap ring. Replace the front bearing with Special Service Tool: 09286-46011 to extract it while Special Service Tool: 09820-00031 will press in a new bearing following a correct installation direction. Special Service Tool: 09286-46011 should be used for removing the rear bearing followed by installation with the help of a press. Begin the magnetic switch terminal kit replacement by utilizing three bolts to remove both the end cover and gasket and plunger. The depth measurement of the contact plate should determine whether it needs replacement when exceeding 0.9 mm (0.035 in.). The new terminal 30 kit parts require installation according to instructions while using Special Service Tool: 09810-38140 to tighten terminal nuts correctly and press down contact plates with a wooden block using a force of 981 N (together with the mentioned torques). The contact plate tightening requires a wooden block to supply 981 N (100 kgf, 221 lbf) of force while using Special Service Tool: 09810-38140 to torque terminal nuts to 17 N.m (173 kgf.cm, 12 ft.lbf). Follow this step carefully to avoid over-tightening the nuts. Install the plunger and new gasket and end cover with their three bolts after cleaning contact surfaces while tightening these bolts to 2.5 N.m (25 kgf.cm, 22 in.lbf).