×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2001 Toyota Celica Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rack And Pinions found

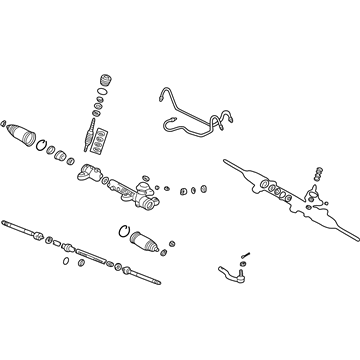

- Product Specifications

- Other Name: Link Assembly, Power Steering; Rack and Pinion Assembly; Steering Gearbox; Gear Assembly; Gear Assembly, Power Steering(For Rack & Pinion)

- Replaces: 44200-20880, 44200-29025

- Part Name Code: 44250

- Item Weight: 22.10 Pounds

- Item Dimensions: 50.7 x 10.5 x 6.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44200-20881

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

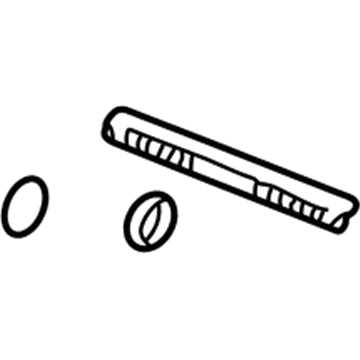

- Product Specifications

- Other Name: Rack Sub-Assembly, Power; Rack And Pinion Rack Gear, Front; Steering Gearbox; Steering Rack; Rack; Rack Sub-Assembly, Power Steering

- Position: Front

- Part Name Code: 44204

- Item Weight: 5.50 Pounds

- Item Dimensions: 32.4 x 3.1 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 44204-20400

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Celica Rack And Pinion

Looking for affordable OEM 2001 Toyota Celica Rack And Pinion? Explore our comprehensive catalogue of genuine 2001 Toyota Celica Rack And Pinion. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2001 Toyota Celica Rack And Pinion Parts Q&A

- Q: How to remove and reinstall the Rack And Pinion on 2001 Toyota Celica?A: The first step to remove rack and pinion includes making sure front wheels point directly ahead followed by removing steering wheel pad and steering wheel. Begin the rack and pinion removal process by taking off RH and center and LH engine under covers before disconnecting the RH and LH tie rods ends along with the No. 2 intermediate shaft assembly. Apply Special Service Tool: 09023-38400 to disconnect the pressure feed and return tubes and then remove the tube clamp by unbolting it. Begin the work by removing the engine hood after disconnecting the column hole cover sub-assembly. A technician can attach the engine sling device by removing engine hangers bolts and the No. 2 cylinder head cover followed by PCV hose disconnection and correct installation of the No. 1 and No. 2 engine hangers with specified part number and torque standards. Lower ball joint should be disconnected from the lower suspension arm and stabilizer bar followed by unfastening the engine rear mount insulator and front suspension member through removing bolt (bolt A) and 3 nuts until the engine front mount insulator and front suspension member can be detached by removing 2 bolts (bolt B). A transmission jack should be used to hold the front suspension member with lower suspension arm while you take out 6 bolts (C, D, E) to remove this assembly. The PS rack and pinion assembly should be extracted by removing four bolts then marking the intermediate extension and control valve shaft before unbolted and removing both components. The first installation step includes attaching the engine rear mount bracket using three bolts and the insulator using the specified through bolt torque values. The PS rack and pinion assembly should be installed by aligning matching numbers on PS stopper and claws before installing the bolt which gets fastened with 4 bolts on the front suspension member at specified torque requirements. The front suspension member should be reinstalled with lower suspension arm and PS rack and pinion assembly using 6 bolts according to their precise torque specifications (position C D and E). Install engine front mount insulator and front suspension member pairs through bolt B and use 2 bolts (bolt B) while front suspension member and engine rear mount insulator pairs connect through bolt A and installment of 3 nuts at their specified torque level. Attache the stabilizer bar using its nut while restoring lower ball joint to lower suspension arm followed by a removal of the engine sling device from engine hangers. Before finishing reconnect the PCV hoses and position the No. 2 cylinder head cover with its 4 bolts while returning the engine hood into place. Fasten the column hole cover sub-assembly to the tube clamp using the specified torque of the bolt while using Special Service Tool: 09023-38400 at the specified torque to attach pressure feed and return tubes. Proceed with installation of the engine under covers beginning with the LH and continuing to the center and finally the RH assembly while reconnecting the No. 2 intermediate shaft and the RH and LH tie rod ends. Set the front wheels directly before positioning the spiral cable correctly and installing the steering wheel to matchmark specifications. Tighten the steering wheel set nut loosely at this stage. The power steering bleeding procedure should be performed followed by centering the steering wheel and torquing the steering wheel set nut to 50 Nm (510 kgf-cm, 37 ft. lbs.) while installing the steering wheel pad and checking front wheel alignment.