×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2001 Toyota Camry Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Timing Belts found

2001 Toyota Camry Timing Belt

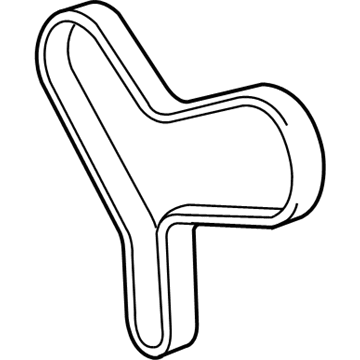

Part Number: 13568-09080$60.54 MSRP: $84.98You Save: $24.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Timing; Engine Timing Belt; Timing Belt Kit

- Replaces: 13568-09050

- Part Name Code: 13568

- Item Weight: 1.00 Pounds

- Item Dimensions: 14.0 x 12.1 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13568-09080

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Camry Timing Belt

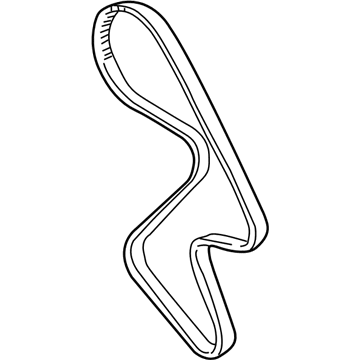

Part Number: 13568-09041$43.13 MSRP: $60.03You Save: $16.90 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Timing; Engine Timing Belt; Timing Belt Kit

- Manufacturer Note: (L)

- Replaces: 13568-74010, 13568-03010, 13568-79025, 13568-79225, 13568-74020, 13568-79095, 13568-74011, 13568-74012

- Part Name Code: 13568

- Item Weight: 1.10 Pounds

- Item Dimensions: 14.0 x 11.8 x 2.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13568-09041

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Camry Timing Belt

Looking for affordable OEM 2001 Toyota Camry Timing Belt? Explore our comprehensive catalogue of genuine 2001 Toyota Camry Timing Belt. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2001 Toyota Camry Timing Belt Parts Q&A

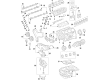

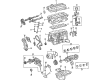

- Q: How to remove and install the timing belt on 2001 Toyota Camry?A: Remove generator, RH front wheel, fender apron seal, and power-steering belt; disconnect ground strap, remove engine moving control rod and No.2 RH engine mount. Disconnect high-tension cords and spark plugs; remove timing belt covers, set No.1 to TDC, remove idlers, pulleys, timing belt, inspect.