×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

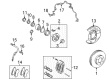

OEM 2000 Toyota Tacoma Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

2000 Toyota Tacoma Caliper, Driver Side

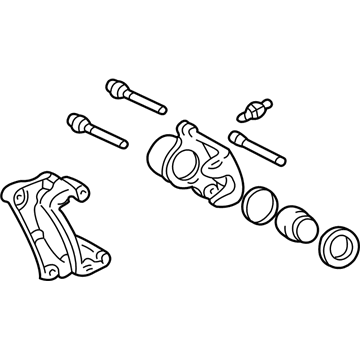

Part Number: 47750-04030$264.79 MSRP: $378.07You Save: $113.28 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Part Name Code: 47750

- Item Weight: 11.30 Pounds

- Item Dimensions: 10.0 x 7.6 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-04030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

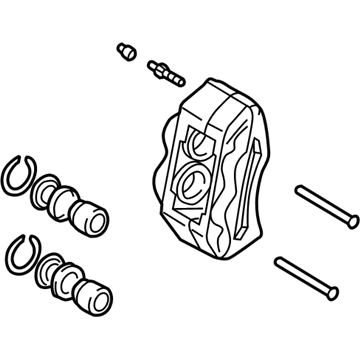

Product Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Manufacturer Note: (L)

- Position: Driver Side

- Replaces: 47750-35100

- Part Name Code: 47750

- Item Weight: 13.70 Pounds

- Item Dimensions: 10.3 x 7.5 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-04040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

Product Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Manufacturer Note: (L)

- Position: Passenger Side

- Replaces: 47730-35100

- Part Name Code: 47730

- Item Weight: 12.20 Pounds

- Item Dimensions: 10.0 x 7.8 x 5.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-04040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730

- Item Weight: 11.80 Pounds

- Item Dimensions: 10.3 x 7.5 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-04030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Tacoma Brake Caliper

Looking for affordable OEM 2000 Toyota Tacoma Brake Caliper? Explore our comprehensive catalogue of genuine 2000 Toyota Tacoma Brake Caliper. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Tacoma Brake Caliper Parts Q&A

- Q: How to service and repair the brake caliper on 2000 Toyota Tacoma?A: Service and repair of the brake caliper starts with removing the front wheel before tightening it to 103 Nm (1,050 kgf-cm, 76 ft. lbs.). Start by disconnecting the flexible hose by uninstalling both the union bolt and 2 gaskets from the caliper then detaching the hose itself while torquing it to 30 Nm (310 kgf-cm, 22 ft. lbs.). Put the flexible hose lock into the caliper lock hole before reinstalling. Remove the caliper through the process of unbolting the 2 mounting bolts at 123 Nm (1,250 kgf-cm, 90 ft. lbs.). Proceed by first removing the clip then taking out the pins and anti-rattle spring and lastly remove two pads alongside four anti-squeal shims. Reverse the installation procedures until completion when you will need to add brake fluid to the reservoir then bleed the system for leaks inspection.