×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Solara Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Control Arms found

2000 Toyota Solara Control Arm, Rear

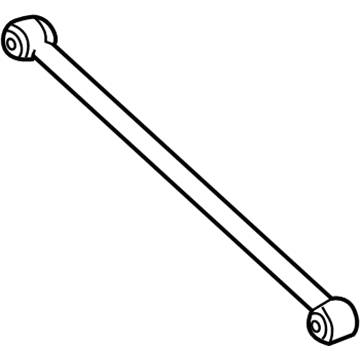

Part Number: 48710-33060$131.95 MSRP: $186.80You Save: $54.85 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Assembly, Rear Suspension; Suspension Control Arm; Lateral Link; Lateral Arm; Front Lateral Arm

- Position: Rear

- Replaces: 48710-06010

- Item Weight: 5.10 Pounds

- Item Dimensions: 1.9 x 1.5 x 1.5 inches

- Condition: New

- SKU: 48710-33060

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

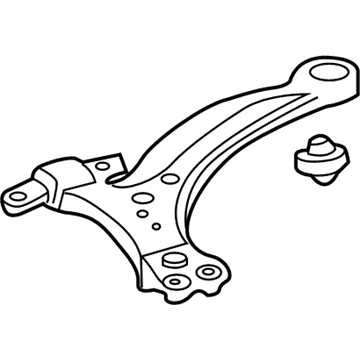

2000 Toyota Solara Lower Control Arm, Driver Side

Part Number: 48069-07030$193.96 MSRP: $276.93You Save: $82.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left; Control Arm Assembly; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm; Control Arm

- Position: Lower Driver Side

- Part Name Code: 48069

- Item Weight: 7.60 Pounds

- Item Dimensions: 19.7 x 3.3 x 15.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48069-07030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Solara Lower Control Arm, Passenger Side

Part Number: 48068-07030$193.96 MSRP: $276.93You Save: $82.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm; Control Arm Assembly; Control Arm; Arm Sub-Assembly, Front Suspension, Lower Passenger Side

- Position: Passenger Side

- Part Name Code: 48068

- Item Weight: 8.10 Pounds

- Item Dimensions: 19.3 x 3.2 x 15.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48068-07030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Solara Control Arm

Looking for affordable OEM 2000 Toyota Solara Control Arm? Explore our comprehensive catalogue of genuine 2000 Toyota Solara Control Arm. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Solara Control Arm Parts Q&A

- Q: How to service and repair the front control arm on 2000 Toyota Solara?A: The repair process of the front control arm begins with wheel removal from the front end. The removal process starts by detaching the lower suspension arm from the lower ball joint by unfastening its bolt and two nuts. The removal process starts by unscrewing the lower suspension arm at its front side using two bolts and the rear side bolt with a nut. After detachment of the arm with the stopper, remove the lower suspension arm bushing stopper. Bushing replacement requires Special Service Tool: 09649-17010, 09710-04081 as well as a steel plate and press to remove the old bushing and then Special Service Tool: 09238-47012, 09649-17010 and press to install a new bushing while ensuring proper orientation. The installation process begins by applying 206 Nm (2,100 kgf-cm, 152 ft. lbs.) torque to connect the lower suspension arm with the front suspension member. Next, connect the lower suspension arm to the lower ball joint with 127 Nm (1,300 kgf-cm, 94 ft. lbs.) torque. Then, reinstall the front wheel using 103 Nm (1,050 kgf-cm, 76 ft. lbs.) torque and verification of front wheel alignment needs to be performed.